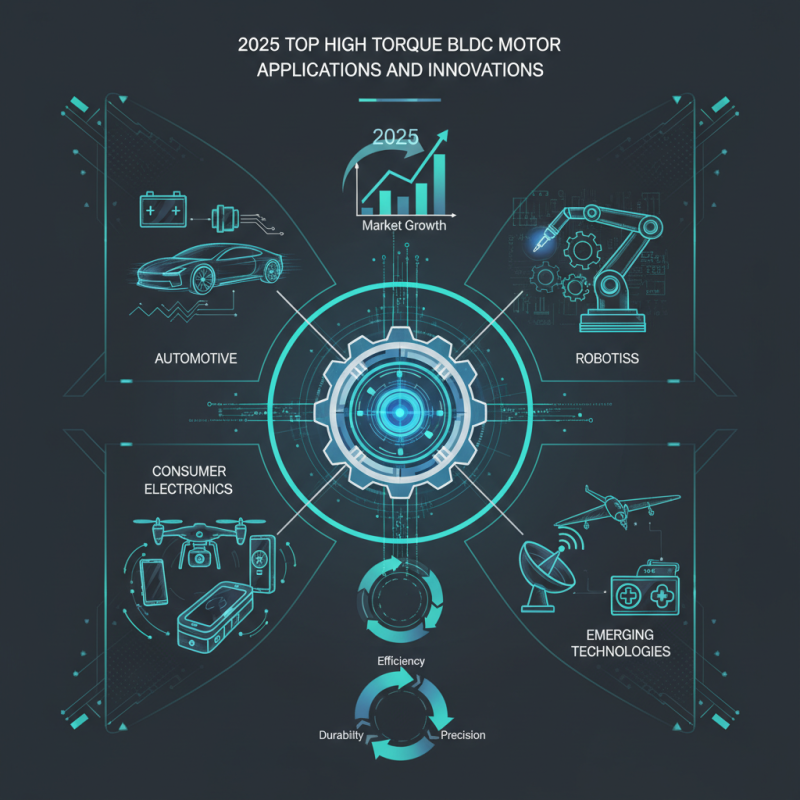

As industries continue to evolve in the quest for higher efficiency and innovative solutions, the demand for High Torque BLDC Motors is on a prominent rise. According to a recent market research report by Grand View Research, the global market for BLDC motors is expected to reach USD 40 billion by 2025, driven by their increasing applications in automotive, robotics, and consumer electronics. This surge in demand highlights the pivotal role that High Torque BLDC Motors play in enhancing performance, durability, and energy efficiency across various sectors.

Dr. Emily Chen, a noted expert in electric motor technologies, emphasizes the significance of this trend, stating, "High Torque BLDC Motors are revolutionizing the way we approach automation and precision engineering, allowing for unprecedented levels of control and efficiency." Innovations in design and materials are propelling these motors to the forefront of technological advancements, fostering applications that were previously deemed unattainable. From improving efficiency in electric vehicles to enabling precise movements in industrial robotics, the impact of High Torque BLDC Motors on modern engineering continues to expand.

As we look toward 2025, understanding the latest applications and innovations surrounding High Torque BLDC Motors becomes essential for industry leaders and stakeholders. Exploring emerging technologies and market dynamics will not only illuminate the future landscape of the industry but also offer insights into maximizing the potential of these powerful motors in various applications.

The high torque BLDC (Brushless Direct Current) motor market is expected to witness significant advancements in 2025, driven by innovations that enhance efficiency and performance across various applications. Industry reports project that the global market for BLDC motors could reach USD 33.5 billion by 2025, with a compound annual growth rate (CAGR) of approximately 10.6% between 2020 and 2025. These advancements are attributed to the push for more energy-efficient solutions and the growing demand in sectors such as automotive, aerospace, and industrial automation.

Key innovations in high torque BLDC motors include the integration of advanced materials and smart technologies. The development of high-density magnetic materials significantly improves torque output while reducing size and weight. Furthermore, the incorporation of IoT (Internet of Things) capabilities allows for real-time monitoring and predictive maintenance, which enhances operational efficiency and reduces downtime. According to a recent analysis, smart motors equipped with IoT technologies are estimated to save up to 30% in energy costs, making them an attractive option for manufacturers looking to optimize production processes.

Additionally, advancements in motor control algorithms, particularly in vector control and field-oriented control, are set to enhance performance even further. These technologies allow for more precise control of motor functions, which can lead to smoother operation and improved responsiveness in demanding applications. As industries increasingly seek to leverage automation and robotics, the demand for high torque BLDC motors that deliver both power and efficiency will continue to rise, positioning them at the forefront of technological innovation in 2025.

In 2025, various industries are poised to leverage the advancements in high torque Brushless DC (BLDC) motors, marking a significant shift towards enhanced efficiency and performance. The automotive sector stands out as a primary beneficiary, particularly with the growing demand for electric vehicles (EVs). High torque BLDC motors enable vehicles to achieve better acceleration and greater power, crucial for both passenger and commercial applications. Additionally, their compact design and high efficiency make them ideal for integrating into advanced driver-assistance systems (ADAS) and autonomous vehicles, significantly enhancing their operational capabilities.

The robotics industry is another area experiencing a transformation through the use of high torque BLDC motors. These motors' precision and reliability are critical for robotic arms and automated machinery, enabling complex tasks in manufacturing, healthcare, and logistics. Moreover, advancements in motion control technologies allow for improved responsiveness and accuracy, which are essential in environments where safety and precision are paramount. As industries continue to prioritize automation and efficiency, the role of high torque BLDC motors will become increasingly central in driving innovation and performance across diverse applications.

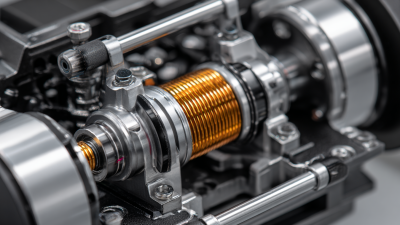

The efficiency and power density of modern Brushless DC (BLDC) motors are critical performance metrics that influence their application across various industries. In recent years, advancements in materials and manufacturing techniques have led to significant improvements in these areas. High-efficiency motors are designed to minimize energy losses through optimized rotor and stator designs, as well as improved magnetic materials. This not only reduces operational costs but also enhances the overall sustainability of the systems using these motors.

Power density, the measure of how much power can be generated in a given volume or mass, is becoming increasingly vital in sectors such as automotive and aerospace. Compact, lightweight BLDC motors with high power density are essential for applications where space and weight are at a premium. Innovations in cooling methods, such as advanced thermal management solutions, are enabling these motors to operate efficiently while maintaining high performance. As technology continues to evolve, we can expect to see further enhancements that will pave the way for more efficient, powerful, and compact BLDC motor solutions in the future.

The integration of Brushless DC (BLDC) motors into smart automation systems is increasingly pivotal in various industries, driving innovations that enhance operational efficiency and performance. According to a report by MarketsandMarkets, the global BLDC motor market is anticipated to reach USD 24.51 billion by 2025, growing at a CAGR of 17.5%. This surge highlights the growing reliance on advanced motor technologies in automation applications, from manufacturing to robotics.

Emerging trends in smart automation involve leveraging advanced algorithms, IoT connectivity, and machine learning to optimize the performance of BLDC motors. For instance, with the rise of Industry 4.0, manufacturers are implementing real-time data analytics to monitor motor performance and predict maintenance needs, thereby reducing downtime and operational costs. Moreover, innovations such as sensorless control techniques are gaining traction, allowing for finer control and efficiency in applications ranging from electric vehicles to HVAC systems.

The adoption of energy-efficient BLDC motors is also being propelled by stricter emission regulations and the increasing emphasis on sustainability. As reported by ResearchAndMarkets, the energy efficiency of these motors can be up to 90%, significantly higher than that of traditional brushed motors. This efficiency not only reduces operational costs but also aligns with the global push towards greener technologies, making BLDC motors a cornerstone in the future of smart automation.

| Application | Torque Rating (Nm) | Efficiency (%) | Control Type | Innovation Trends |

|---|---|---|---|---|

| Industrial Automation | 10-20 | 85 | Closed-loop | AI and IoT Integration |

| Robotics | 15-30 | 90 | Sensorless | Enhanced Real-time Control |

| Electric Vehicles | 80-150 | 95 | Vector Control | Battery Management Systems |

| Aerospace | 5-10 | 88 | PWM Control | Lightweight Materials |

| Home Appliances | 1-5 | 80 | Adaptive Control | Smart Home Integration |

As we look towards the future of high torque BLDC motors, the development landscape presents both challenges and opportunities. One of the key challenges is maximizing efficiency while maintaining strength and reliability. Manufacturers must balance these elements to meet the increasing demand for powerful motors in diverse applications, from robotics to electric vehicles. Additionally, the rapid pace of technological advancement calls for continuous innovation in materials and design, enabling motors to perform under more strenuous conditions while minimizing energy loss.

Tips: To tackle efficiency challenges, consider investing in advanced simulation technologies during the design phase. This can help identify potential issues before they arise, allowing for a more streamlined production process and improved motor performance.

At the same time, the rise of renewable energy sources and electric vehicles creates substantial opportunities for high torque BLDC motors. These sectors require motors that can deliver exceptional torque for varied applications without sacrificing energy efficiency. As industries increasingly prioritize sustainability, the development of motors that integrate smart technologies and robust power management systems will be essential.

Tips: Explore collaborations with tech startups focusing on smart motor technology solutions. Partnering with innovators can speed up the introduction of novel features into your product line, keeping you ahead of market demands.