As industries evolve, the demand for more efficient and versatile motor solutions has led to the rise of Frameless BLDC Motors. These motors, characterized by their lightweight and compact design, are increasingly being recognized for their potential to significantly enhance performance across various applications, from robotics to automotive systems. According to Dr. Emily Carter, a leading expert in electric motor technologies, "Frameless BLDC Motors represent the next frontier in motion control, offering unprecedented efficiency and adaptability for modern engineering challenges."

In 2025, we anticipate significant trends shaping the future of Frameless BLDC Motors, driven by technological innovations and changing market demands. As manufacturers seek to improve energy efficiency and reduce physical footprint, these motors are poised to become integral in applications ranging from consumer electronics to aerospace. The industry's exploration of novel materials and advanced manufacturing techniques will further propel the development of these motors, allowing for greater customizability and performance enhancements.

As we delve into the key trends influencing Frameless BLDC Motors, it becomes evident that their impact will extend far beyond traditional applications, ushering in a new era of innovation and efficiency for diverse sectors. Understanding these dynamics is essential for stakeholders aiming to capitalize on the opportunities presented by this cutting-edge technology.

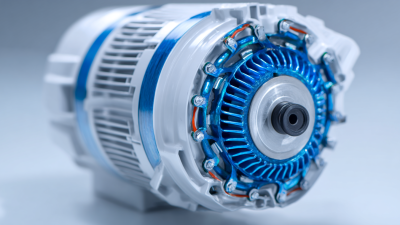

Frameless Brushless DC (BLDC) motors have gained significant traction in various industries due to their unique design and numerous advantages. Unlike conventional motors, frameless BLDC motors eliminate the bulky outer casing, allowing for a compact form factor that can be directly integrated into applications. This design flexibility leads to increased efficiency as these motors can achieve higher power-to-weight ratios, making them ideal for space-constrained environments such as robotics, drones, and medical devices. Their simplified configuration also results in lower thermal resistance, enabling better heat dissipation and higher performance in demanding scenarios.

When considering the integration of frameless BLDC motors, it is crucial to prioritize cooling solutions to maintain optimal performance. Implementing heat sinks or active cooling systems can significantly enhance the longevity and reliability of these motors. Additionally, proper placement within the application can mitigate temperature build-up, ensuring efficient operation.

Another key advantage of frameless BLDC motors is their quiet operation, making them suitable for applications requiring low noise levels, such as in home appliances or healthcare equipment. To maximize benefits, engineers should focus on motor control algorithms that can adapt to varying load conditions, enhancing both performance and efficiency. By leveraging these motors' attributes, manufacturers can innovate and improve products in a variety of fields.

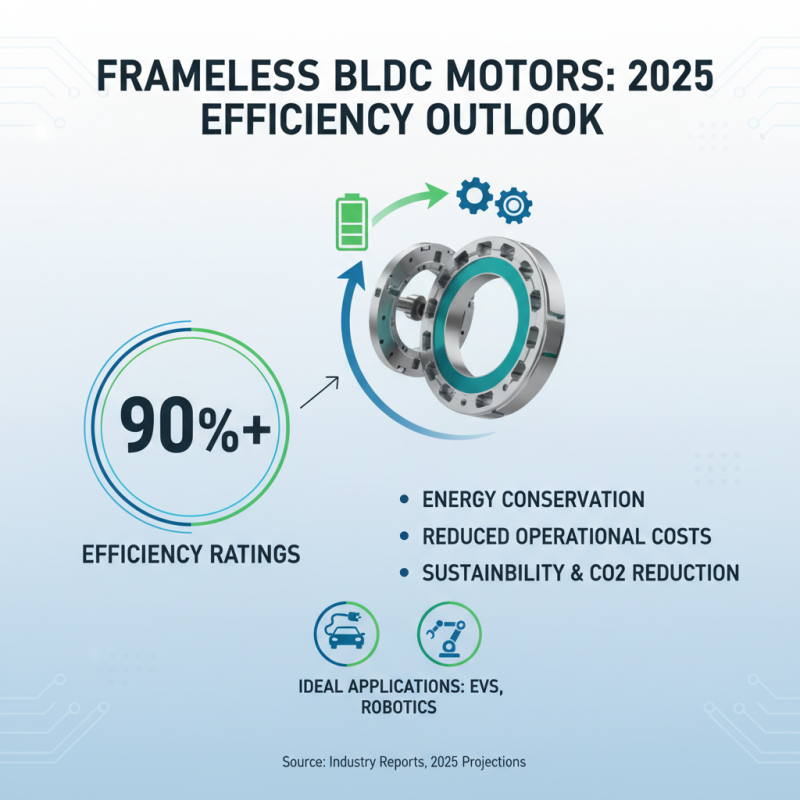

As the demand for high-efficiency motors continues to grow, frameless BLDC motors are emerging as a leading solution across various industries. In 2025, key efficiency metrics will play a significant role in shaping the market landscape. Industry reports indicate that these motors can achieve efficiency ratings exceeding 90%, making them ideal for applications where energy conservation is paramount, such as in electric vehicles and robotics. The reduced energy loss not only lowers operational costs but also contributes to sustainability efforts, aligning with global goals for reduced carbon emissions.

Another crucial metric to watch in 2025 is power density. Frameless BLDC motors are increasingly designed to deliver higher torque and power output in smaller and lighter packages. Reports suggest that advancements in materials and design could lead to power density improvements of up to 30% compared to traditional motor designs. This increase makes frameless BLDC motors suitable for a wider range of applications, from aerospace to medical devices, where space and weight are limiting factors. The combination of high efficiency and superior power density positions frameless BLDC motors as a transformative technology in the realm of motion control.

Frameless BLDC (Brushless DC) motors are rapidly gaining traction across a variety of industries, thanks to their unique design and operational benefits. Unlike traditional motors, frameless BLDC motors provide a compact and lightweight solution that can be integrated directly into applications where space and weight are critical factors. This makes them particularly attractive in automotive applications, robotics, and consumer electronics, where efficient power management and space optimization are paramount. Their inherent design also contributes to increased power density and performance, allowing them to deliver robust functionality in diverse settings.

As industries continue to evolve, the applications of frameless BLDC motors are expanding beyond their traditional realms. In the medical field, for example, these motors are being utilized in advanced surgical instruments and imaging devices, where precision and reliability are essential. Similarly, in automation and manufacturing, frameless BLDC motors are employed in robotics for tasks requiring high precision and responsiveness. The adaptability of these motors also enables their use in renewable energy applications, assisting in the efficient operation of solar tracking systems and wind turbines, thereby promoting sustainable practices across sectors. Their versatility positions frameless BLDC motors as a key player in the drive towards more efficient and innovative technological solutions.

The frameless brushless DC (BLDC) motor technology is experiencing a transformative wave driven by a blend of innovations that enhance efficiency and broaden applications across various sectors. According to a report by Research and Markets, the global market for BLDC motors is projected to reach $38 billion by 2025, reflecting a compound annual growth rate (CAGR) of 10%. This growth can be attributed to the ongoing advancements in magnetic materials, control algorithms, and manufacturing processes that allow for improved power density and energy efficiency.

One of the key innovations in frameless BLDC motors is the development of integrated sensor technologies that enable more precise motor control and feedback. This integration not only reduces the size and complexity of the motor systems but also enhances their performance in demanding environments, such as robotics and aerospace applications. Additionally, the rise of smart technologies and IoT connectivity is fostering a new era of automation, where frameless BLDC motors can be remotely monitored and controlled, resulting in optimized operational efficiencies and predictive maintenance capabilities.

Moreover, the exploration of sustainable materials and eco-friendly manufacturing techniques is setting the stage for a greener future in motor technology. Industry experts predict that the adoption of these sustainable practices in the production of frameless BLDC motors could lead to a 25% reduction in overall manufacturing costs by 2025. As the demand for higher efficiency and environmentally conscious solutions escalates, these innovations will play a critical role in shaping the future landscape of frameless BLDC motor technology.

The development of frameless BLDC (Brushless Direct Current) motors is poised to face several challenges as technologies evolve through 2025. One primary concern is the increasing demand for higher efficiency and performance. The need for motors that not only perform well under varying loads but also consume less energy is crucial. Manufacturers must innovate in materials and designs, focusing on lightweight yet durable components that ensure both efficiency and longevity.

Another challenge lies in the integration of advanced features such as IoT connectivity. As automation and smart technologies become more prevalent, frameless BLDC motors must incorporate sensors and communication protocols to facilitate real-time monitoring and control. This adds complexity to the design and manufacturing processes, requiring a fine balance between enhanced functionalities and the cost of production.

Tips for engineers working in this field include prioritizing modular design, which allows for easier updates and customization based on customer requirements. Additionally, staying informed about advancements in magnetic materials could potentially lead to weight reduction and performance improvements. Exploring collaborations with software developers might also yield innovative solutions for integrating IoT capabilities seamlessly into existing motor designs.