The rise of BLDC Electric Motors (Brushless DC Motors) has significantly transformed various sectors in modern technology, largely attributed to their superior efficiency and performance.

According to a report by MarketsandMarkets, the global BLDC motor market is projected to grow from $20.9 billion in 2021 to $31.2 billion by 2026, demonstrating a substantial compound annual growth rate (CAGR) of 8.4%.

This growth is fueled by the increasing demand for energy-efficient solutions and advancements in robotics, automotive, and consumer electronics.

BLDC electric motors, with their inherent advantages such as reduced maintenance requirements, increased reliability, and high torque-to-weight ratio, are becoming the preferred choice for manufacturers.

As industries progressively shift towards automation and smart technologies, the importance of integrating BLDC electric motors becomes even more evident, paving the way for innovative applications that optimize performance and minimize environmental impact.

BLDC electric motors, with their inherent advantages such as reduced maintenance requirements, increased reliability, and high torque-to-weight ratio, are becoming the preferred choice for manufacturers.

As industries progressively shift towards automation and smart technologies, the importance of integrating BLDC electric motors becomes even more evident, paving the way for innovative applications that optimize performance and minimize environmental impact.

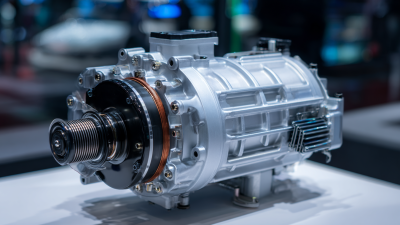

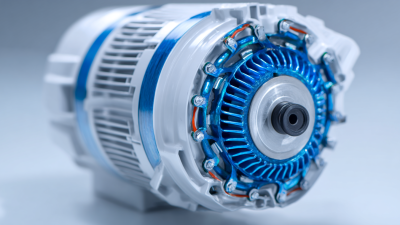

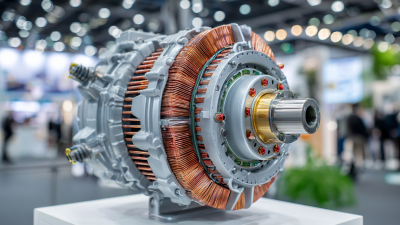

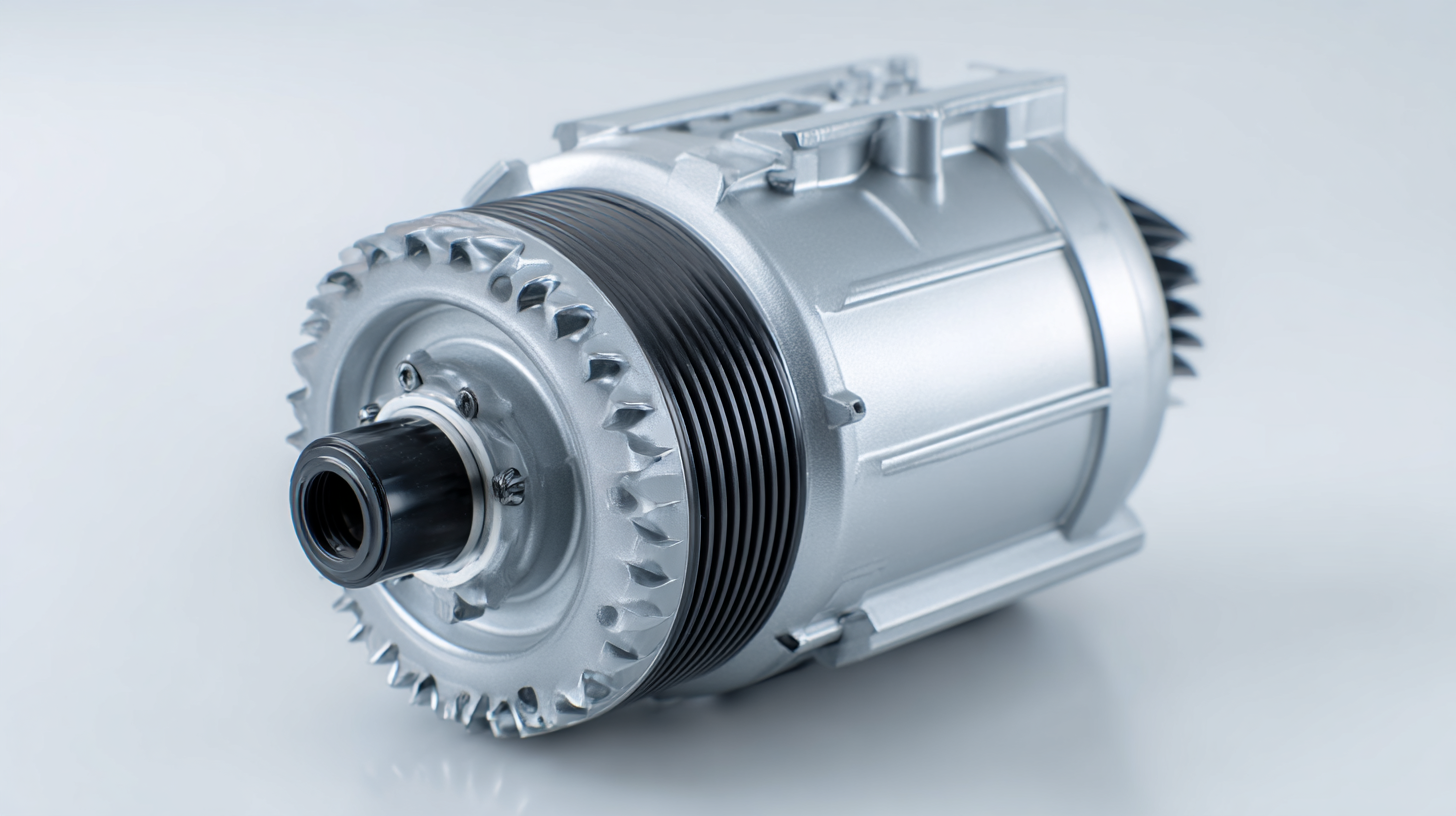

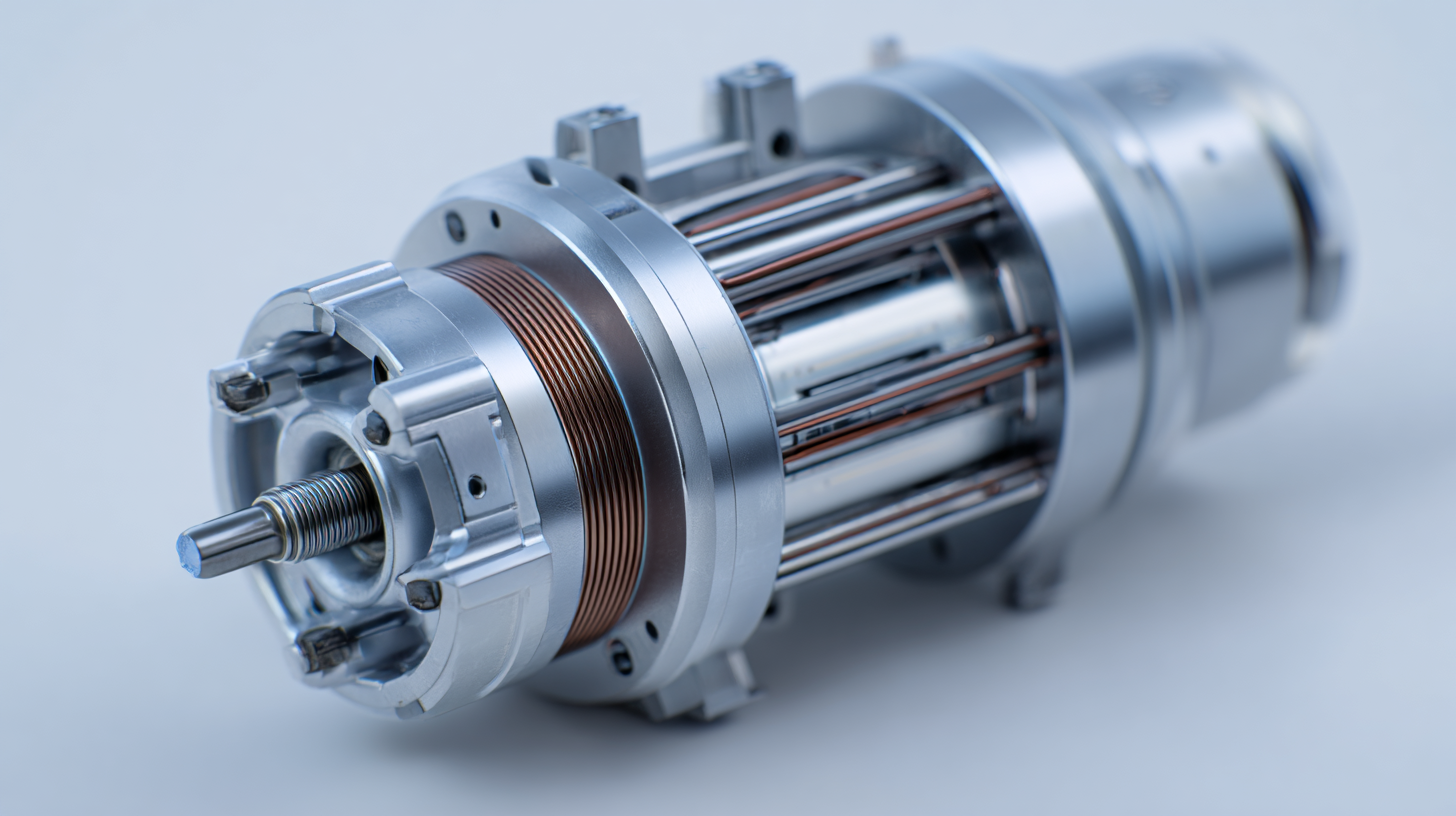

BLDC (Brushless Direct Current) electric motors have gained significant traction in modern technology due to their efficiency and durability. Understanding the basic components of a BLDC motor is crucial to appreciating its advantages. Unlike traditional brushed motors, BLDC motors utilize permanent magnets and electronic controllers, eliminating the need for brushes that wear out over time. This design not only reduces maintenance but also allows for better performance at higher speeds.

One of the standout features of BLDC motors is their ability to maintain high efficiency across a range of speeds. This performance is primarily attributed to their electronic commutation, which optimizes torque and minimizes energy loss. When integrating BLDC motors in your projects, consider the following tips: always match the motor specifications with your application needs, and ensure adequate cooling mechanisms to sustain efficiency during extended use.

Another key component is the rotor, which houses the permanent magnets, while the stator consists of windings that generate a magnetic field when energized. This interaction leads to smooth and high-torque operation. To maximize the lifespan of your BLDC motors, it's important to keep them free from dust and debris, and regularly check the connections to prevent any disruptions in power flow.

The rise of Brushless DC (BLDC) motors has been pivotal in modern technology, particularly as industries seek more efficient and environmentally-friendly alternatives to traditional motors. One primary advantage of BLDC motors is their energy efficiency; they can reach efficiencies of up to 90%, significantly reducing power consumption compared to conventional brushed motors. This high efficiency not only leads to lower operational costs but also contributes to sustainability efforts by minimizing energy waste.

In addition, BLDC motors boast a longer lifespan and reduced maintenance needs due to the absence of brushes, which are prone to wear and tear. This characteristic is particularly beneficial in applications such as household appliances, where reliable performance is critical. Recent industry reports indicate that the global market for BLDC motors is expected to grow at a CAGR of over 10% through the next five years, highlighting the increasing adoption of these motors across various sectors, including automotive and consumer electronics. As the demand for intelligent, energy-efficient solutions intensifies, the advantages of BLDC motors become increasingly evident, positioning them as a leading choice in contemporary motor technology.

| Advantage | Description | Impact on Performance | Typical Applications |

|---|---|---|---|

| High Efficiency | BLDC motors offer up to 90% efficiency due to low resistance and improved design. | Reduced energy consumption and lower electricity costs. | Electric vehicles, drones, renewable energy systems. |

| Compact Size | Smaller footprint compared to traditional motors with similar power ratings. | Easier integration into space-constrained environments. | Home appliances, robotics, medical devices. |

| Low Maintenance | Lacks brushes and minimizes wear and tear, leading to longer lifespan. | Reduced downtime and maintenance costs. | HVAC systems, electric scooters, computer cooling fans. |

| Precise Control | Electronic commutation allows for smooth and precise speed and torque control. | Enhanced performance in applications requiring accuracy. | CNC machines, robotic arms, automotive systems. |

| High Torque-to-Weight Ratio | Delivers more torque per unit weight compared to conventional motors. | Improved power density and performance in lightweight applications. | Electric bicycles, model aircraft, portable tools. |

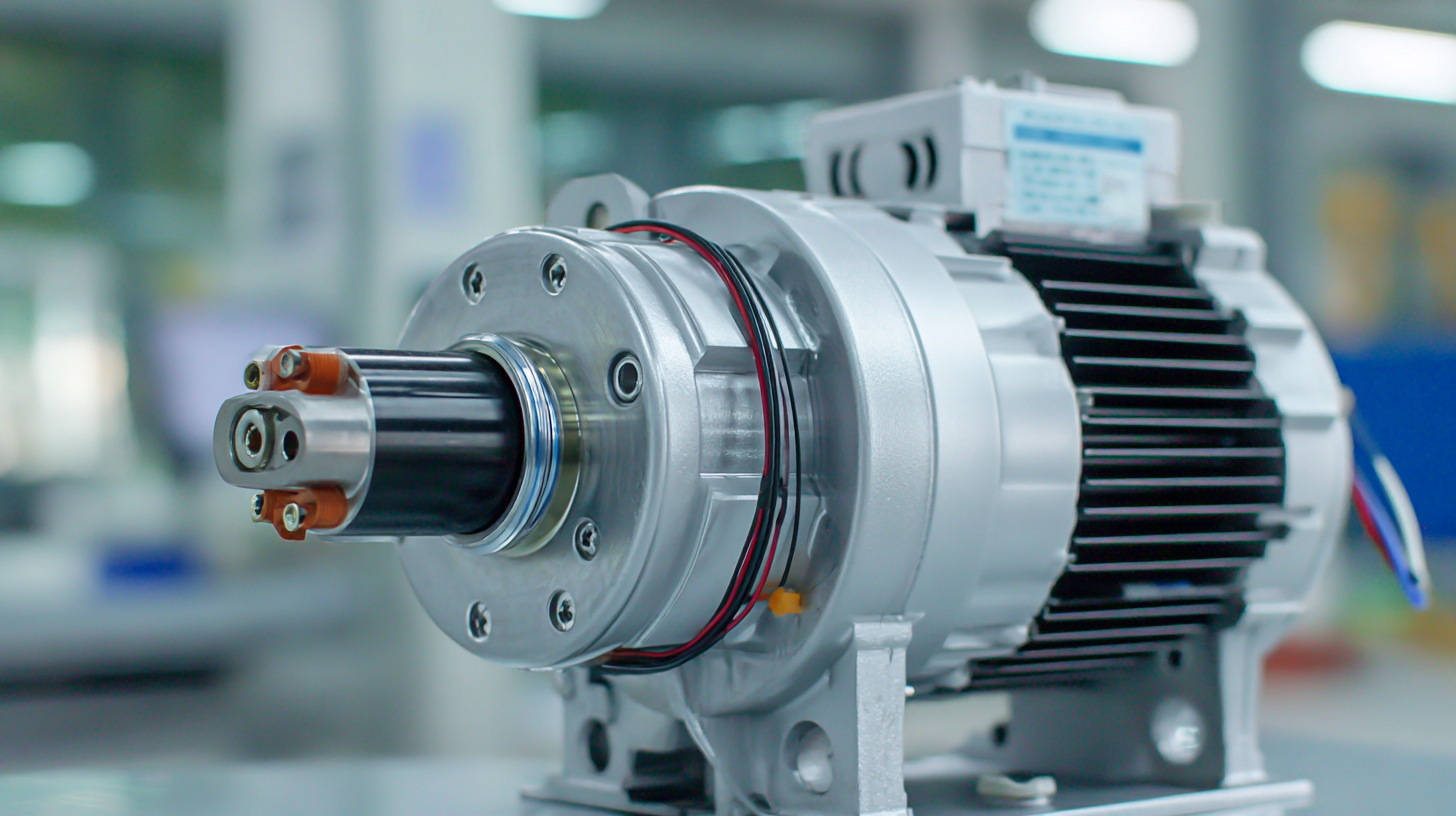

Brushless DC (BLDC) motors are increasingly finding applications across various modern technologies due to their superior efficiency and performance characteristics. In the automotive sector, particularly in electric vehicles (EVs), the adaptive speed control of BLDC motors is crucial for optimizing performance. Recent studies have highlighted the implementation of fuzzy logic in closed-loop speed control systems, improving power efficiency and responsiveness, which is vital for enhancing the driving experience in EVs. As a result, the adoption of BLDC motors in this sector is on the rise, with projections indicating rapid growth as EV technologies evolve.

In industrial applications, the demand for advanced motor control technologies is becoming paramount. One noteworthy advancement is the introduction of the Galvanic Isolated Hex Bridge Inverter designed for three-phase servo/BLDC motors, which enables improved control and safety in high-power applications. Market analysis indicates that industries are increasingly automating processes for precision and reliability, leading to a forecasted CAGR of 4.7% in the polygon mirror scanner motor market through 2035. These advancements underscore the significant role of BLDC motors in modern technology, driving innovations that facilitate greater efficiency across various sectors.

When comparing the costs of Brushless Direct Current (BLDC) motors to conventional motor options, it becomes evident that BLDC motors offer significant advantages in both initial investment and long-term savings. According to a report by the Allied Market Research, the global market for BLDC motors is projected to reach $28.6 billion by 2027, showcasing their rising popularity driven by efficiency and cost-effectiveness. While the upfront cost of BLDC motors may be higher—ranging from 10% to 30% more than traditional brushed motors—their operational efficiency, reduced maintenance needs, and longer lifespan can lead to substantial savings over time.

A key factor in the cost analysis is the energy efficiency of BLDC motors, which can be up to 90% compared to 70% for conventional motors, as reported by the Institute of Electrical and Electronics Engineers (IEEE). This efficiency translates into lower electricity bills, making BLDC motors a more economical choice for applications requiring prolonged use. Additionally, the reduced wear and tear on components due to the lack of brushes in BLDC motors result in fewer replacements and maintenance interventions, further enhancing their economic viability. As industries increasingly focus on sustainability and energy efficiency, the transition to BLDC motors stands out as a strategic investment that aligns with modern technological demands.

The future of BLDC (Brushless Direct Current) motor technology is poised to transform a wide range of industries. With their inherent advantages, such as higher efficiency, reduced maintenance needs, and a compact design, BLDC motors are increasingly being integrated into advanced applications. Industries like automotive and aerospace are already leveraging these motors for electric vehicles and drones, where weight and energy efficiency are critical factors. Furthermore, as global energy demands heighten, the push for sustainable technologies is likely to accelerate the adoption of BLDC motors, as they consume less power and generate less heat compared to traditional motors.

Another significant trend is the advent of smart motor technology. By incorporating IoT (Internet of Things) capabilities, BLDC motors can be monitored and controlled in real-time, allowing for enhanced performance and predictive maintenance. This integration is expected to streamline operations and reduce costs across manufacturing, robotics, and renewable energy sectors. As industries move towards automation and smart manufacturing, the role of BLDC motors will become increasingly vital, enabling precise control and efficiency that are essential in today's competitive landscape. The ongoing development in materials and electronics will further enhance the capabilities of BLDC motors, positioning them as a cornerstone technology for future innovations.