In recent years, the demand for efficient and reliable motor control solutions has surged, largely driven by advancements in technology and increased energy efficiency requirements. Brushless DC Motor Control has emerged as a leading alternative to traditional brushed motors, offering significant advantages such as higher efficiency, reduced maintenance costs, and longer operational lifespan. According to a report by Research and Markets, the global brushless DC motor market is projected to reach approximately $40 billion by 2026, growing at a CAGR of around 13% from 2021. This growth is largely attributed to the rising adoption of automation in various sectors, including automotive, industrial machinery, and consumer electronics. As industries continue to prioritize energy efficiency and performance, understanding the advantages of Brushless DC Motor Control becomes crucial for engineers and manufacturers aiming to stay competitive in a rapidly evolving technological landscape.

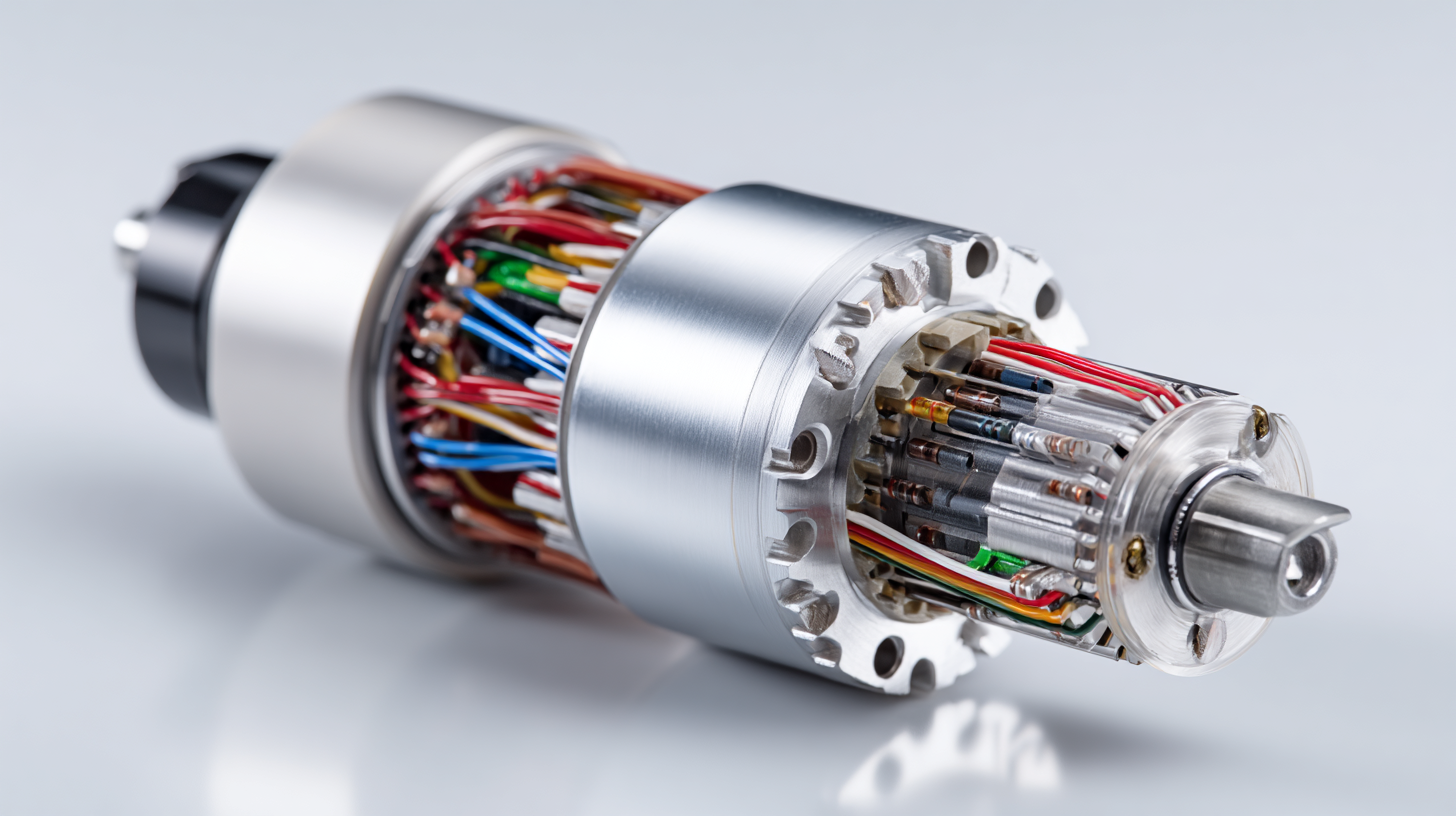

Brushless DC motors (BLDC) are becoming increasingly vital in modern applications due to their significant contributions to energy efficiency. Unlike traditional brushed motors, BLDC motors eliminate the friction and wear associated with brushes, leading to reduced energy loss and enhanced longevity. This inherent efficiency makes them ideal candidates for a wide range of uses, from electric vehicles to industrial machinery, where energy conservation is paramount.

The expanding global market for brushless DC motors reflects their essential role in contemporary technology. With projections indicating that the brushless DC motor market will reach approximately USD 66.57 billion by 2033, an impressive growth rate of 11.63% from 2025, it is clear that industries are recognizing the value of these motors. Their ability to deliver high performance while utilizing less energy not only meets regulatory demands for energy-efficient solutions but also supports sustainable practices in the quest for reduced carbon footprints. As technological advancements continue, BLDC motors retain their position at the forefront of innovation, enabling smarter and greener systems across various sectors.

Brushless DC (BLDC) motors have become a cornerstone in modern technology, especially in applications requiring precision and control. Unlike traditional brushed motors, BLDC motors eliminate mechanical brushes, resulting in reduced friction and increased efficiency. According to a report by MarketsandMarkets, the global brushless DC motor market is projected to reach $29.16 billion by 2025, growing at a CAGR of 16.5%. This surge is primarily attributed to their superior performance characteristics, which allow for enhanced precision in motion control systems.

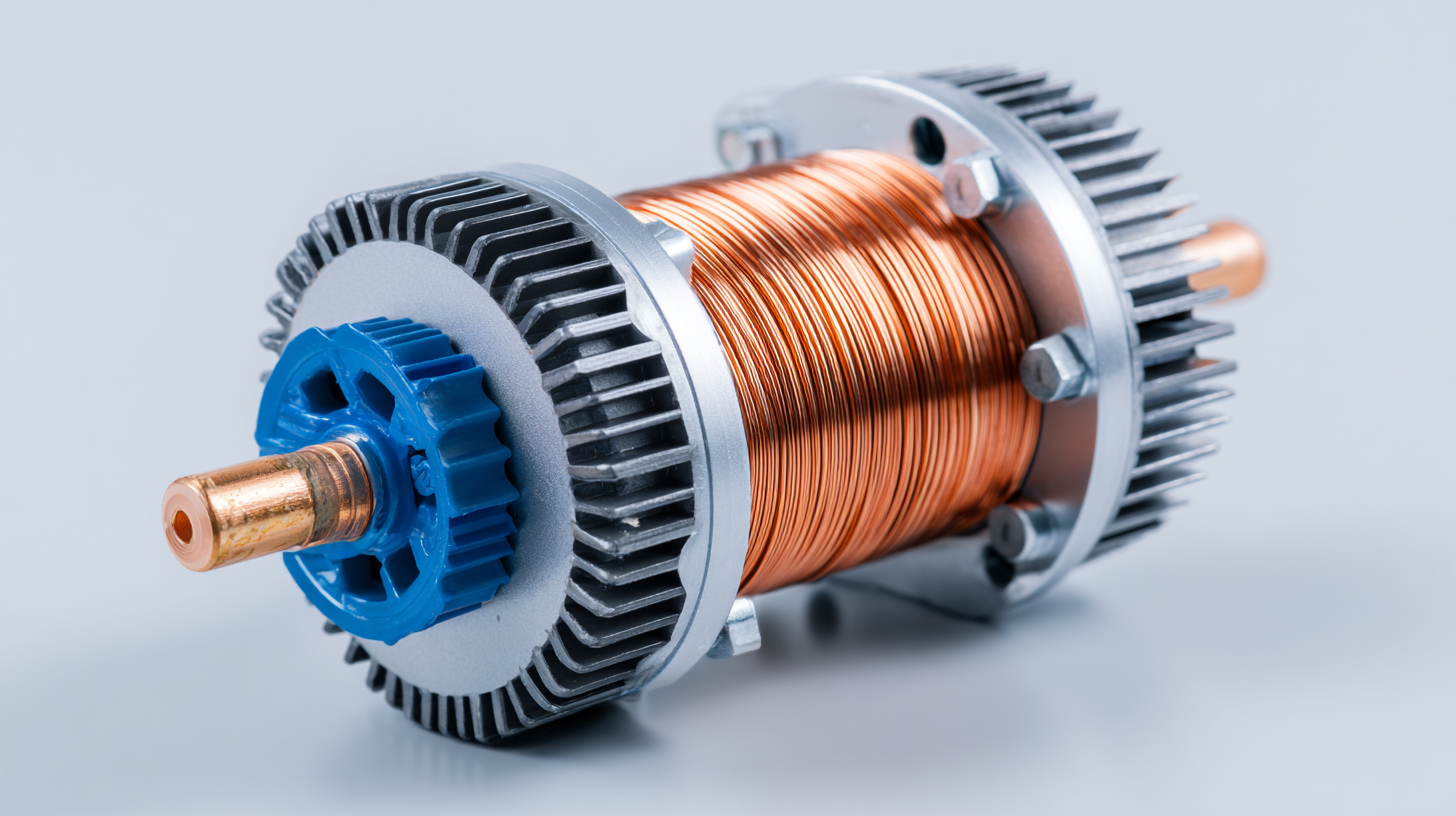

One of the key advantages of BLDC technology is the ability to deliver high torque at low speeds, which is critical in applications ranging from robotics to aerospace. The efficiency gains are significant; a study published in the IEEE Transactions on Industry Applications indicates that BLDC motors can achieve up to 90% efficiency under optimal conditions, compared to 75-80% for brushed counterparts. This level of efficiency directly translates to longer operational lifespans and lower energy costs, making them particularly appealing for industries focused on sustainability and performance optimization. Additionally, the advanced control algorithms used in BLDC systems facilitate smoother operation and precise positioning, enhancing overall system accuracy and reliability.

Brushless DC (BLDC) motors are increasingly recognized for their lower maintenance costs, making them an attractive option in modern technology. Unlike traditional brushed motors, which rely on physical contact between brushes and a commutator, BLDC motors utilize electronic controllers that minimize wear and tear. This design leads to a significant reduction in the frequency of maintenance interventions, translating to lower operational costs. For industries that demand reliability and efficiency, this reduced need for upkeep is particularly beneficial.

Moreover, the application of BLDC motors in off-grid water pumping systems illustrates their advantages not only in terms of efficiency but also sustainability. For instance, 3HP brushless submersible solar pumps can deliver substantial volumes of water for irrigation, enhancing agricultural productivity while reducing energy costs. As the market for brushless DC motors continues to expand, projected to reach USD 66.57 billion by 2033, the implications for maintenance and operational economies become increasingly significant. This trend reflects a broader movement toward sustainable technologies that combine efficiency with cost-effectiveness, essential for meeting the demands of modern agriculture and beyond.

| Feature | Brushless DC Motors | Brushed DC Motors |

|---|---|---|

| Maintenance Frequency | Low (1-2 times a year) | High (3-4 times a year) |

| Lifespan | Up to 10,000 hours | Around 1,500 hours |

| Operational Noise | Very Low | Moderate to High |

| Efficiency | 85-90% | 70-80% |

| Control Precision | High (closed-loop control) | Moderate |

| Initial Cost | Higher | Lower |

| Long-term Cost Saving | Significant | Minimal |

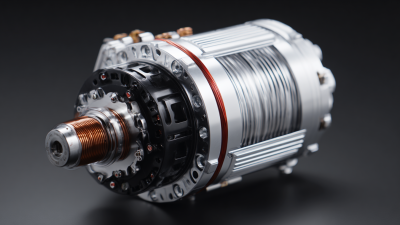

Brushless DC (BLDC) motors are increasingly vital in the fields of automation and robotics, primarily due to their efficient power management and durability. Unlike traditional brushed motors, BLDC motors eliminate the need for mechanical brushes, resulting in reduced friction and wear. This technological advancement leads to enhanced longevity and reliability, essential features for applications in modern manufacturing and automated systems. As reported, the global DC electric motor market was valued at $45.10 billion in 2024 and is projected to grow significantly, reaching an estimated $78.82 billion by 2032, highlighting the increasing integration of these advanced motors in various sectors.

The advantages of brushless DC motors extend to their superior control capabilities, which facilitate precise motion and increased responsiveness in robotics. These motors can easily interface with sophisticated control systems, allowing for real-time adjustments to speed and torque. As automation technology becomes more prevalent, having motors that can adapt quickly to high-performance requirements becomes crucial. Industry reports indicate that the growth of sectors reliant on automation will only accelerate, making BLDC motors a key component in the development of innovative robotic solutions that enhance efficiency and productivity across various industries.

Brushless DC motors (BLDC) are gaining traction in various industries, primarily driven by the imperative for environmental sustainability. Recent studies indicate that BLDC motors can be up to 90% efficient, compared to only 60-70% for traditional brushed motors. This increased efficiency not only leads to reduced energy consumption but also minimizes carbon footprints, making these motors a preferred choice in sustainable manufacturing practices. As industries aim to comply with stringent environmental regulations, the adoption of these motors is becoming a strategic imperative.

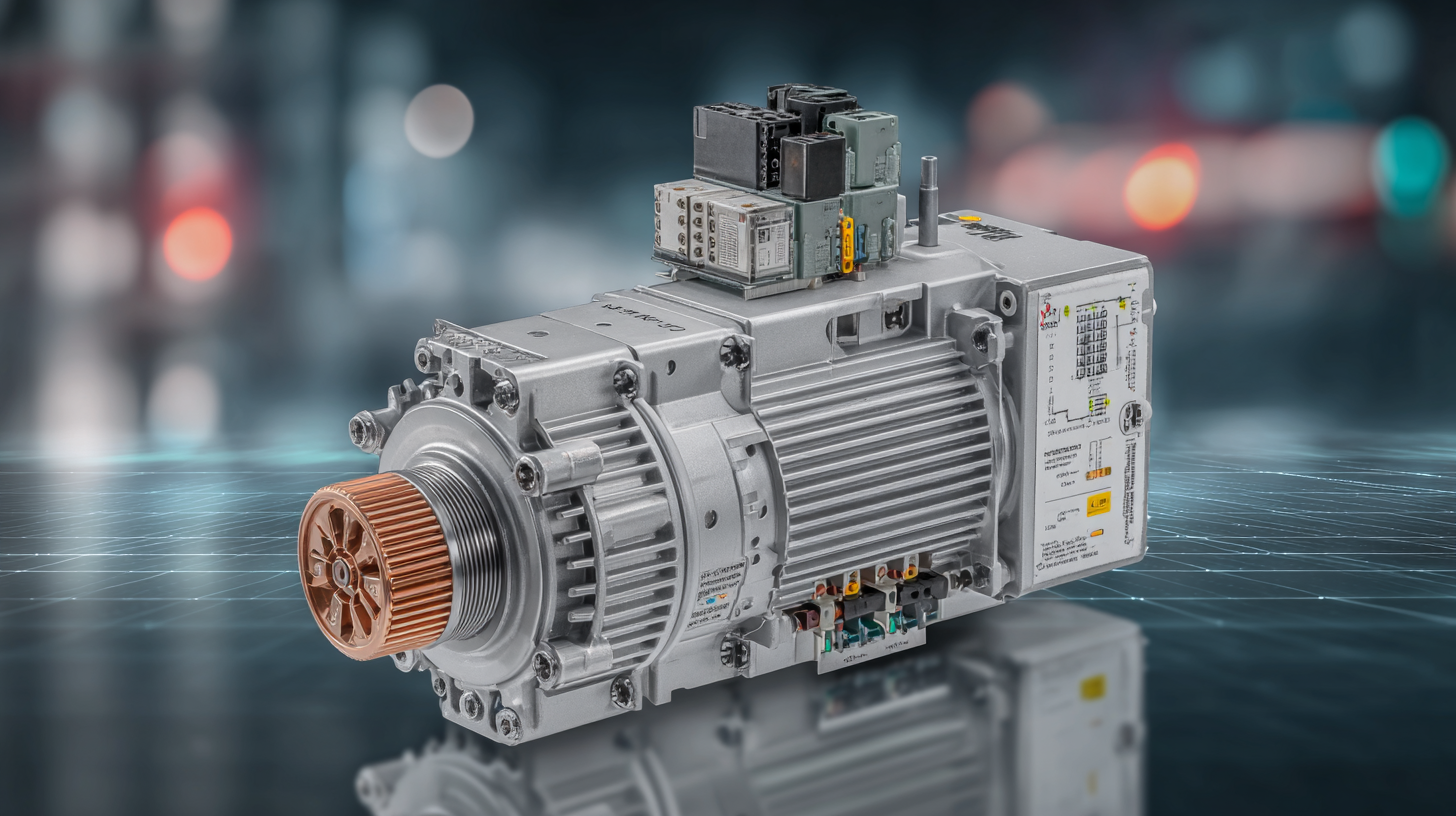

One significant application of BLDC motors is in electric vehicles (EVs), where their efficiency considerably extends driving ranges and reduces the overall impact on the environment. According to a report from the International Energy Agency, the number of electric vehicles on the road is projected to reach 250 million by 2030, with BLDC motors playing a crucial role in this transition. The lower maintenance requirements and longer operational lifespan of these motors further contribute to their sustainable appeal, as they result in less waste and reduced resource depletion over time.

**Tips:**

When considering the transition to brushless DC motors, businesses should evaluate not only the initial investment but also the long-term savings in energy and maintenance costs. Additionally, adopting BLDC technology can enhance corporate sustainability efforts, appealing to a growing consumer base that prioritizes environmentally friendly products.