The increasing demand for energy-efficient solutions in various applications has led to the rising popularity of Bldc Drive systems. These brushless direct current drives are not only known for their efficient energy consumption but also for their ability to improve overall system performance. By utilizing advanced technology and innovative design, Bldc Drive systems offer significant advantages over traditional motor systems, making them an ideal choice for a wide range of industries, from manufacturing to renewable energy generation.

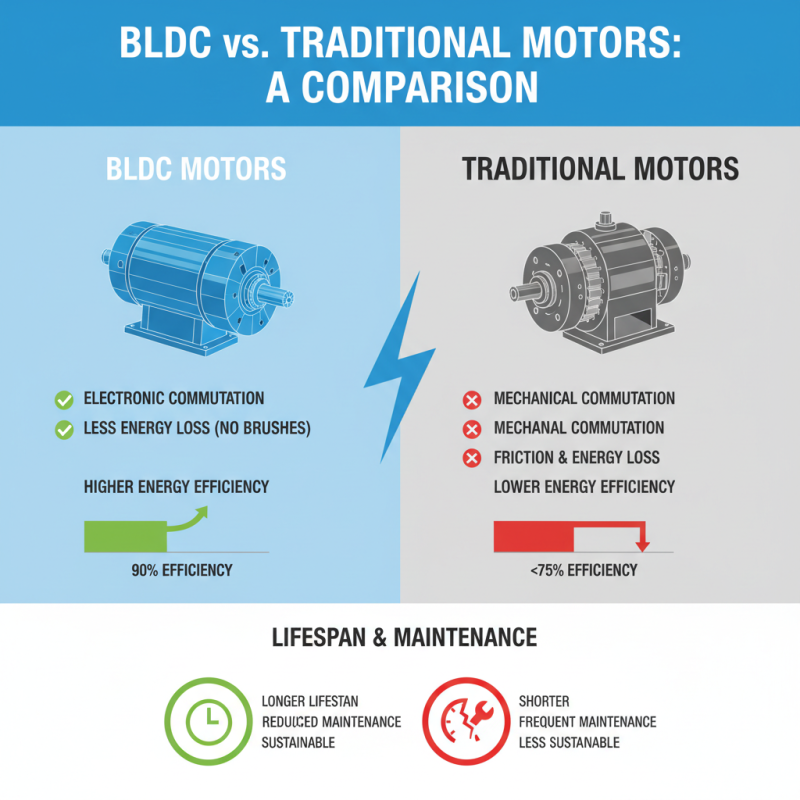

One of the primary benefits of Bldc Drives is their superior efficiency, which results in reduced energy costs and a lower carbon footprint. Unlike conventional motors that rely on brushes for operation, Bldc Drives use electronic commutation, leading to less energy loss and enhanced durability. This efficiency not only provides economic benefits but also supports environmental sustainability initiatives that are increasingly important in today's world.

Moreover, the application of Bldc Drive systems enhances system control and performance. These drives can provide precise speed and torque control, enabling better adaptation to varying load conditions. This level of control is critical in applications where precision and reliability are essential, thus making Bldc Drives a compelling choice for modern, energy-efficient applications. As industries strive to meet energy efficiency standards and reduce environmental impacts, the adoption of Bldc Drive technology is set to play a pivotal role in shaping a more sustainable future.

BLDC (Brushless Direct Current) drive systems have emerged as a prominent choice for energy-efficient applications due to their unique operational advantages. One of the top benefits of these systems is their high efficiency. BLDC motors convert a higher percentage of electrical energy into mechanical energy compared to traditional brush-type motors. This efficiency reduces energy consumption significantly, which is crucial in applications where power savings can lead to lower operational costs and reduced environmental impact.

Additionally, BLDC systems are known for their longevity and low maintenance requirements. Since they lack brushes, there is less friction and wear, which means these motors can operate continuously without the need for frequent replacements or servicing. This not only extends the lifespan of the equipment but also minimizes downtime, making them an ideal choice for critical and continuous operations.

Tips for maximizing the efficiency of BLDC systems include ensuring proper temperature management, as excessive heat can reduce performance. Additionally, selecting the correct size and type of motor for your application can optimize energy use and enhance operational effectiveness. Regularly reviewing load profiles can also highlight opportunities for further energy savings, making the most out of the inherent advantages of BLDC drive systems.

Brushless DC (BLDC) motors are rapidly gaining traction in various sustainable applications due to their remarkable energy efficiency and reduced environmental footprint. According to the International Energy Agency (IEA), electric motors account for approximately 40% of global electricity consumption, making their efficiency improvements crucial for sustainable development. BLDC motors, with their high power-to-weight ratio and minimal energy losses, often operate with efficiencies exceeding 90%. This positions them as an excellent choice for applications in renewable energy systems, electric vehicles, and industrial automation.

One of the key features of brushless DC motors is their lack of brushes, which not only reduces mechanical wear and tear but also minimizes maintenance requirements. The absence of brushes leads to lower heat generation and noise levels, promoting a quieter and more efficient operating environment. Furthermore, BLDC motors utilize advanced electronic control systems, allowing for precise speed and torque management that enhances overall system performance. The U.S. Department of Energy reported that implementing variable frequency drives, which are commonly paired with BLDC motors, can lead to energy savings of 50% or more in various industrial applications.

Tips: When selecting a motor for an energy-efficient application, consider the specific torque and speed requirements for optimal performance. Additionally, look for systems that integrate advanced control technologies to maximize energy savings and meet sustainability goals. By choosing BLDC motors, industries can significantly contribute to reducing their carbon footprint while benefiting from enhanced reliability and efficiency.

The adoption of Brushless Direct Current (BLDC) technology has significantly transformed the landscape of energy consumption across various applications. One of the most notable impacts of BLDC systems is their inherent efficiency. Because these systems utilize electronic commutation instead of mechanical brushes, they reduce energy loss associated with friction and wear. This leads to a higher conversion rate of input electrical energy into mechanical energy, bolstering performance and minimizing energy wastage. As a result, industries leveraging BLDC motors can experience substantial reductions in their overall energy consumption, making these systems an ideal choice for energy-efficient applications.

Moreover, BLDC technology offers improved control and precision over motor performance, allowing for customizable operation that aligns with specific energy requirements. Advanced speed and torque control capabilities enable these systems to operate at optimal performance levels, reducing unnecessary energy use. Additionally, the ability to fine-tune motor functions means that devices can be designed to consume less power during low-load scenarios. This adaptability enhances the overall energy efficiency of systems, facilitating substantial cost savings and contributing to a more sustainable future. By decreasing energy consumption, BLDC systems not only benefit individual organizations through lower operational costs but also play a critical role in the global pursuit of reduced carbon footprints and environmental preservation.

When comparing BLDC (Brushless Direct Current) motors to traditional motor systems, several key factors come into play that highlight the advantages of BLDC technology. One of the most significant aspects is energy efficiency. BLDC motors utilize electronic commutation, which eliminates the friction and energy loss associated with brushes found in traditional brushed motors. This results in lower energy consumption and improved performance in a wide range of applications. Additionally, the absence of brushes reduces maintenance needs and enhances motor lifespan, making BLDC systems a more sustainable choice in the long run.

Another important factor in this comparative analysis is torque delivery. BLDC motors are capable of providing high torque at low speeds, which is particularly beneficial for applications that require precision and reliability. In contrast, traditional motors often experience torque loss at lower speeds, leading to inefficiencies in operation. Furthermore, the compact design of BLDC systems allows for better integration in space-constrained environments, which is increasingly demanded in modern technology. Overall, the benefits of BLDC motors in terms of energy efficiency, torque performance, and compactness clearly demonstrate their superiority in many applications compared to traditional motor systems.

Brushless DC (BLDC) drive systems have gained significant traction in various energy-efficient applications due to their unique design and operational advantages. In industries such as HVAC, electric vehicles, and renewable energy systems, the efficiency gains from implementing BLDC systems are evident. For example, in HVAC systems, BLDC motors can modulate their speed proactively, ensuring optimal energy consumption while maintaining desired temperature levels. This adaptability leads to lower energy bills and decreased greenhouse gas emissions, making them a sustainable choice for modern buildings.

In the automotive sector, the transition towards electric vehicles has highlighted the benefits of BLDC motors, which offer higher torque at lower speeds compared to traditional motors. This characteristic enables electric vehicles to accelerate more efficiently while maximizing battery life. Real-world implementations show that vehicles equipped with BLDC drive systems experience better performance and increased range, proving essential in the shift toward cleaner transportation. Similarly, in renewable energy applications, BLDC systems are utilized in wind turbines and solar trackers, allowing for improved performance and energy output, thus enhancing the overall effectiveness of renewable resources.

This chart demonstrates the energy efficiency gains achieved by using Brushless DC (BLDC) drive systems in various real-world applications. The data illustrates the percentage of energy savings compared to traditional systems.