In recent years, the adoption of Brushless DC Motor Drives (BLDC) in various sectors has significantly transformed the landscape of modern applications. According to a market analysis by Grand View Research, the global brushless DC motor market is expected to reach $26.4 billion by 2025, driven by increased efficiency and advancements in automation technology. This surge highlights the growing recognition of BLDCs in optimizing performance across diverse industries such as automotive, consumer electronics, and industrial automation.

Experts in the field, like Dr. Emily Chen, a noted researcher in motor technologies, emphasize the advantages of these drives, stating, "The transition to Brushless DC Motor Drives not only enhances energy efficiency but also extends operational lifespans, making them a cornerstone of contemporary engineering solutions." With benefits such as reduced maintenance costs, higher reliability, and improved thermal performance, it's evident that the shift towards brushless technology is not just a trend but a necessary evolution in the quest for greater efficiency and sustainability.

As industries strive to meet the demands of a rapidly changing technological landscape, understanding the top benefits of Brushless DC Motor Drives becomes crucial for engineers and decision-makers. This exploration reveals how integrating BLDC technology can lead to impressive gains in both productivity and cost-effectiveness, ultimately shaping the future of modern applications.

A Brushless DC (BLDC) Motor Drive is an advanced type of electric motor that operates without the traditional brushes found in conventional DC motors. Instead, it employs electronic commutation, utilizing a digital controller to switch the motor phases, which significantly enhances efficiency and reduces mechanical wear. This design leads to lower maintenance requirements and longer operational life. According to a report from MarketsandMarkets, the global brushless motor market is projected to grow from $20.48 billion in 2022 to $31.83 billion by 2027, highlighting the increasing demand and adoption of BLDC motors across various industries.

One of the primary advantages of using a BLDC Motor Drive is its superior energy efficiency, often exceeding 90%. This efficiency translates into reduced energy costs, which is crucial for industries aiming to minimize operational expenses. A study conducted by the Electric Power Research Institute (EPRI) estimates that the transition to brushless motor technology could lead to energy savings of up to 30% in certain applications. Furthermore, the integrated control system of a BLDC motor allows for precise speed and torque regulation, making it ideal for applications requiring consistent performance, such as in robotics and aerospace. As industries increasingly focus on automation and energy sustainability, the benefits provided by Brushless DC Motor Drives are becoming indispensable.

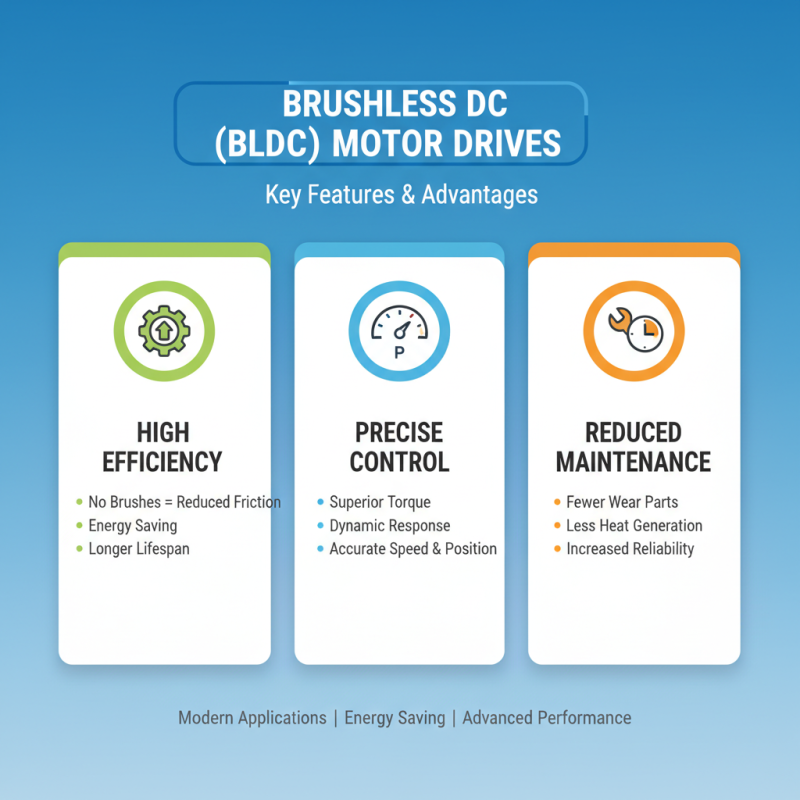

This chart displays the top 10 benefits of using Brushless DC Motor Drives in modern applications, emphasizing efficiency, longevity, and performance improvements.

Brushless DC (BLDC) motor drives offer several key features that enhance their applicability in various modern applications. One of the most significant advantages is their high efficiency, resulting from the elimination of brushes, which reduces friction and heat generation. This efficiency not only conserves energy but also allows for longer operational life and reduced maintenance needs. Furthermore, BLDC motors provide superior torque characteristics and dynamic response, making them suitable for applications that require precise speed and position control.

Another critical feature of brushless DC motor drives is their compact design. The absence of brushes means that these motors can be built in a more streamlined manner, saving space and weight, which is particularly advantageous in portable devices and applications with limited installation areas. Additionally, BLDC motor drives integrate advanced control algorithms that enable smooth operation across a range of speeds and loads. This capability, combined with their quiet performance, makes them ideal for use in environments where noise reduction is essential, such as in medical equipment and consumer electronics. Overall, the unique features of brushless DC motors contribute significantly to their versatility and effectiveness in addressing the demands of contemporary technological developments.

Brushless DC motors have gained prominence in recent years, owing to their numerous advantages over traditional brushed motors. One of the most significant benefits is their enhanced efficiency. Brushless motors operate with less electrical resistance and heat generation, which means they can convert more electrical energy into mechanical energy. This efficiency translates into lower operational costs, making them a preferred choice for applications ranging from household appliances to industrial machinery.

Another advantage of brushless DC motors lies in their longer lifespan. Unlike traditional motors that rely on brushes to create a connection, brushless motors eliminate the friction and wear associated with these components. As a result, they require less maintenance and have a higher reliability, making them ideal for mission-critical applications where downtime is not an option.

**Tips**: When considering brushless motors for your applications, always evaluate the specific torque and speed requirements to ensure optimal performance. Additionally, keep in mind that while their initial investment may be higher, the long-term savings in maintenance and energy costs can make brushless motors the smart choice. Finally, ensure that you choose the correct driver for your motor, as this can greatly affect efficiency and performance.

| Benefit | Description |

|---|---|

| Higher Efficiency | Brushless DC motors can achieve efficiency levels above 90%, reducing energy costs and heat generation. |

| Longer Lifespan | Without brushes, there is reduced wear and tear, leading to extended motor life and lower maintenance. |

| Compact Size | Brushless motors are generally smaller and lighter, making them ideal for space-constrained applications. |

| High Torque at Low RPM | They provide excellent torque characteristics at low speeds, useful in various applications such as robotics. |

| Quiet Operation | The lack of brushes and commutators leads to quieter operation, beneficial in noise-sensitive environments. |

| Better Control | Advanced control options allow for precise speed and position control, enhancing functionality in automation systems. |

| Improved Thermal Performance | Heat dissipation is more effective due to better design and materials, allowing for higher performance in demanding applications. |

| Regenerative Capabilities | Brushless motors can return energy back to the system, promoting efficiency in power usage. |

| Wide Range of Applications | Used in diverse fields from automotive to industrial automation, making them versatile components for modern systems. |

| Compatible with Modern Electronics | Integration with electronic circuits is seamless, enhancing automation and control strategies. |

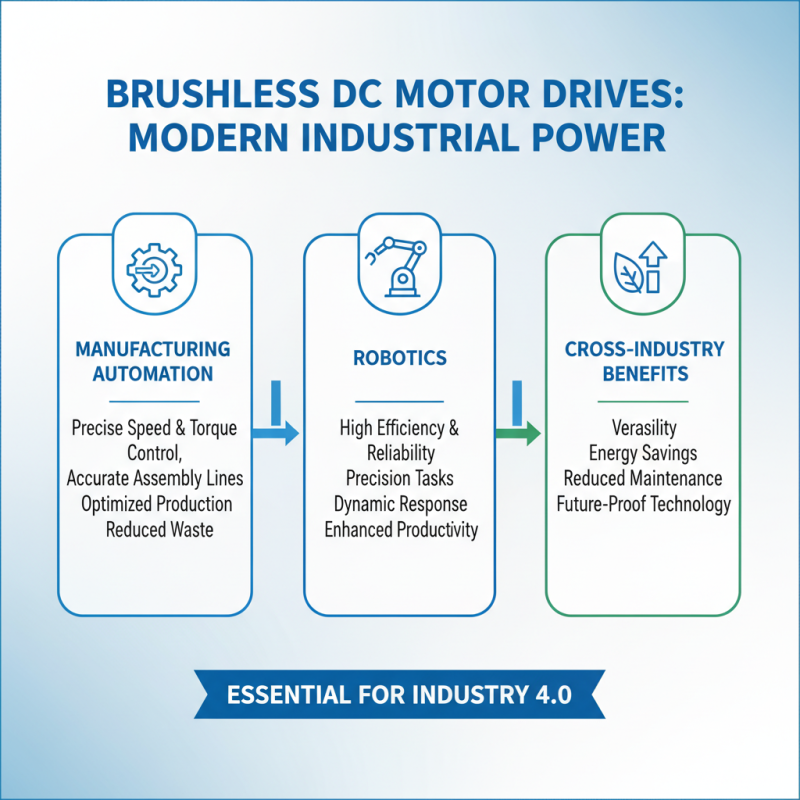

Brushless DC motor drives have increasingly become essential in various modern industries due to their efficiency and versatility. In manufacturing automation, these motors provide precise control over speed and torque, enabling highly accurate operations in assembly lines. Their ability to respond quickly to changes in demand allows industries to optimize production, reduce waste, and improve overall productivity. Consequently, brushless DC motor drives are widely employed in robotics, where their high efficiency and reliability are crucial for precision tasks.

In the automotive sector, brushless DC motors are integral to electric and hybrid vehicles, contributing to enhanced energy efficiency and reduced maintenance needs. These motors facilitate smooth acceleration and precise handling, significantly improving the driving experience. Furthermore, in the aerospace industry, brushless DC motor drives are utilized in applications such as flight control systems and actuation mechanisms, where reliability and performance are paramount. As these motors continue to gain traction, their applications are likely to expand further, redefining the standards of efficiency and performance across diverse sectors.

Future trends in brushless DC motor drive technology highlight the increasing integration of advanced electronics and artificial intelligence, which are set to revolutionize the industry. The evolution towards smarter motor drives is evident, as manufacturers aim to enhance efficiency and performance across various applications. The incorporation of real-time diagnostics and predictive maintenance capabilities allows these systems to operate optimally, reducing downtime and extending the lifespan of the motor drives.

Moreover, the push for sustainability and energy efficiency has galvanised research into materials and designs that minimize environmental impact. Emerging technologies, such as wide-bandgap semiconductors, offer greater power density, which translates to lighter and more compact designs. This not only improves the overall performance of brushless DC motors but also aligns with the global demand for greener solutions in industries ranging from automotive to renewable energy.

As the technology progresses, we can expect further innovations that improve torque control and reduce electromagnetic interference, paving the way for more versatile and reliable motor systems tailored to the demands of modern applications.