The advent of technology in industrial applications has brought about significant advancements, particularly in the realm of motors. Among these, the Industrial Brushless Motor stands out as a transformative solution for boosting efficiency and performance across various sectors. Unlike traditional brushed motors, brushless motors utilize electronic controllers to optimize operation, consequently reducing mechanical wear and prolonging lifespan. This transition has led to a paradigm shift in how industries approach power and output, ensuring that operations run smoother and more reliably.

In today's competitive landscape, organizations are continually seeking ways to enhance productivity while minimizing operational costs. The Industrial Brushless Motor provides a compelling answer by offering higher torque-to-weight ratios and improved energy efficiency. This not only helps in cutting down electricity costs, but also supports sustainable practices by lowering energy consumption and emissions. As industries strive for greater effectiveness and reliability, understanding the benefits of these advanced motors becomes crucial for informed decision-making in equipment procurement and process optimization.

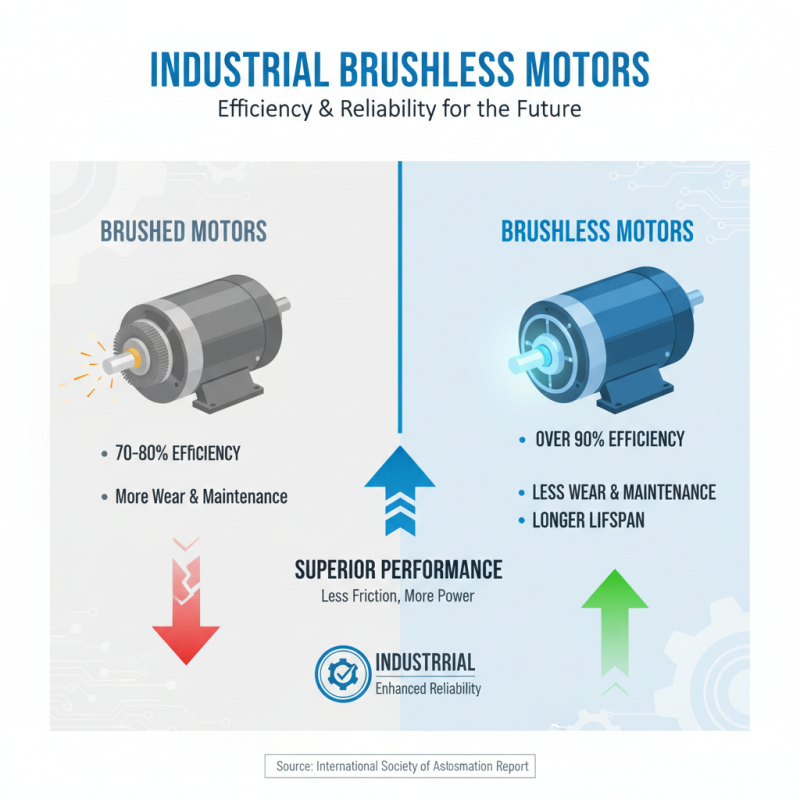

Industrial brushless motors are becoming increasingly popular due to their efficiency and reliability in various applications. Unlike traditional brushed motors, brushless motors operate without physical brushes, which reduces friction and wear, thus leading to enhanced performance. This design allows for smoother operation and less maintenance, contributing to longer lifespans. According to a report by the International Society of Automation, brushless motors can achieve efficiency ratings of over 90%, compared to about 70-80% for brushed counterparts, making them a superior choice for industrial applications.

The components of industrial brushless motors primarily include the rotor, stator, and electronic controller. The rotor, which is attached to the output shaft, rotates within the magnetic field produced by the stator. The stator consists of several windings that create a rotating magnetic field when energized. This setup is further complemented by the electronic controller, which regulates the power supply and monitors the motor's performance, allowing for precise control over speed and torque. As reported by MarketsandMarkets, the global brushless motor market is projected to grow at a CAGR of 9.5% from 2021 to 2026, underscoring the increasing reliance on these innovative motors in sectors such as robotics, aerospace, and manufacturing.

Brushless motors have emerged as a revolutionary alternative to traditional brushed motors, particularly in industrial applications where efficiency and performance are paramount. One of the primary advantages of brushless motors is their enhanced reliability. Without brushes, these motors experience significantly less wear and tear over time, resulting in a longer lifespan and reduced maintenance requirements. This feature not only saves time and money in the long run but also minimizes operational disruptions caused by failures and repairs.

Another notable benefit lies in the efficiency of brushless motors. These motors operate on a principle that eliminates energy loss associated with friction between brushes and commutators found in their brushed counterparts. As a result, brushless motors provide better performance, converting a higher percentage of electrical energy into mechanical energy. This increased efficiency translates into lower energy consumption, which is vital for industries looking to reduce their carbon footprint and operational costs. Furthermore, brushless motors offer improved thermal management and quieter operation, enhancing the overall working environment in industrial settings.

Brushless motors have gained immense popularity in various industrial applications due to their ability to enhance efficiency and optimize energy use. According to a report by the International Energy Agency (IEA), electric motor systems, which include brushless motors, account for roughly 20-30% of global electricity consumption. By switching to brushless motor technology, industries can substantially reduce energy consumption, with studies indicating that these motors can improve energy efficiency by up to 50% compared to their brushed counterparts.

One of the primary ways brushless motors achieve enhanced efficiency is through the elimination of friction losses associated with brushes. This design leads to improved thermal management and longer lifespan, resulting in less frequent maintenance and reduced operational costs. The U.S. Department of Energy highlights that brushless motors typically operate with efficiency ratings of 85% to 95%, significantly outperforming traditional motors that often fall between 70% to 80%. This efficiency translates not only into lower energy bills but also into a smaller carbon footprint, reinforcing the growing need for sustainable practices within the industrial sector.

Furthermore, brushless motors provide precise control of speed and torque, allowing for better performance in demanding applications. The ability to maintain consistent performance under varying load conditions translates to optimized production processes and minimized energy waste. According to a report by the Electric Power Research Institute, implementing brushless motors across industrial systems can lead to an overall reduction in energy costs of up to 25%, demonstrating their value as a key technology for enhancing efficiency and performance in modern industries.

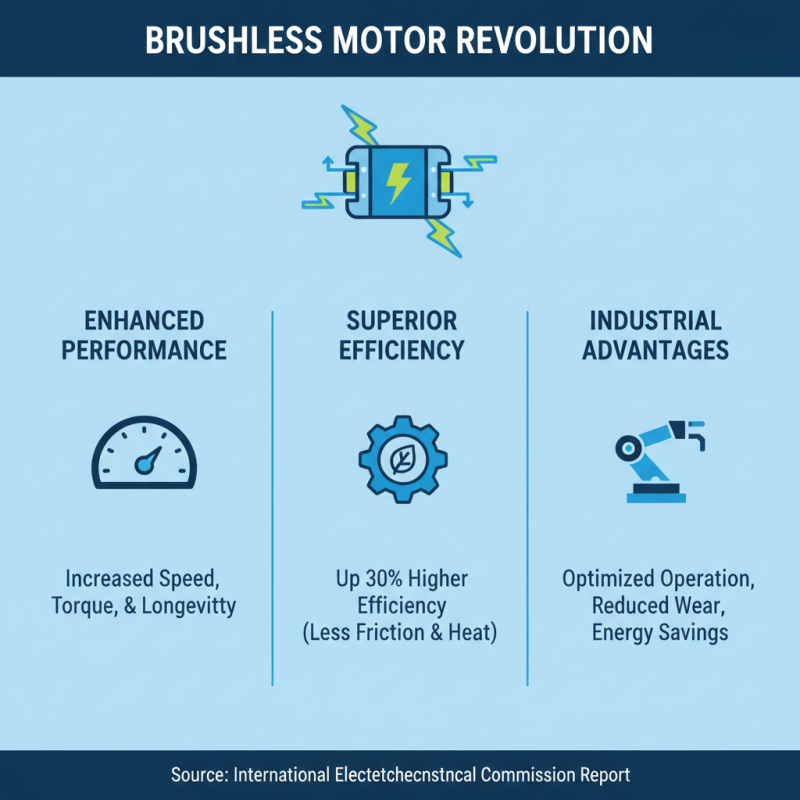

Brushless motors have revolutionized industrial applications, particularly in improving performance metrics such as speed, torque, and longevity. According to a report by the International Electrotechnical Commission, brushless motors are known to provide up to 30% higher efficiency compared to traditional brushed motors, primarily due to reduced friction and heat generation during operation. This increase in efficiency directly translates to enhanced performance, allowing machinery to operate at optimized speeds without risking overheating or unnecessary wear.

In terms of torque, brushless motors exhibit superior characteristics, providing consistent and high torque output across a broader speed range. Research from the Electric Power Research Institute indicates that brushless motors can deliver up to 40% more torque than their brushed counterparts at similar sizes, making them ideal for applications requiring rapid acceleration and precision. Furthermore, the durability of brushless motors is noteworthy; they typically have a lifespan that exceeds 15,000 hours of continuous operation, which is significantly longer than the average lifespan of brushed motors. This longevity reduces maintenance costs and increases overall equipment uptime, creating a more reliable industrial environment.

Brushless motors are increasingly becoming the preferred choice across various industries due to their efficiency and performance advantages. In the manufacturing sector, for instance, brushless motors are widely used in robotic arms and conveyor systems, enabling precise control and reduced maintenance costs. Their design eliminates the need for brushes, which not only leads to less wear and tear but also allows for a longer lifespan and improved reliability. This is particularly advantageous in high-output environments where downtime can significantly impact productivity.

In the automotive industry, brushless motors power electric vehicles, contributing to enhanced performance and energy efficiency. They provide better torque characteristics and a smoother operation, which is essential for the consumer's driving experience. Moreover, in the medical field, brushless motors are utilized in surgical instruments and diagnostic equipment, where precise movements are critical. The versatility of these motors means they can be tailored for a range of applications, from high-speed drills to low-speed gear systems, thus making them vital for innovation and development in these sectors. The impact of brushless motors is profound, driving advancements in technology and contributing to the sustainability of various industries.

| Application Industry | Efficiency Improvement (%) | Performance Feature | Lifespan (years) | Typical Application |

|---|---|---|---|---|

| Automotive | 20 | High Torque | 15 | Electric Vehicles |

| Manufacturing | 15 | Noise Reduction | 10 | Conveyor Systems |

| Aerospace | 25 | Compact Design | 20 | Drones |

| Medical | 30 | Precision Control | 12 | Surgical Tools |

| Robotics | 18 | Responsiveness | 15 | Automated Machines |