In today’s rapidly advancing technological landscape, the versatility and reliability of DC motors make them indispensable components in a wide array of applications. DC motors, or direct current motors, convert electrical energy into mechanical energy, allowing for precise control of speed and torque. This capability has positioned them as a preferred choice in industries ranging from automotive to robotics, and even in household appliances.

The benefits of using DC motors extend beyond just their operational efficiency. Their compact size and simplicity in design facilitate easy integration into various systems, providing engineers with the flexibility needed to innovate and enhance performance. Furthermore, DC motors are known for their excellent responsiveness, which is crucial for applications requiring quick and accurate adjustments. This introduction explores the top ten advantages of utilizing DC motors, highlighting their role in driving progress across multiple sectors and emphasizing why they are considered a cornerstone in modern engineering solutions.

DC motors, or direct current motors, are widely utilized due to their simplicity and efficiency. At their core, these motors convert electrical energy into mechanical energy through the interaction of magnetic fields. The basic components of a DC motor include the stator, rotor (or armature), commutator, and brushes. The stator generates a constant magnetic field, while the armature is the rotating part that carries the current. The commutator plays a crucial role by reversing the direction of the current flow through the armature windings, ensuring continuous rotation.

The functionality of DC motors relies on the principles of electromagnetism. When current flows through the armature, it creates a magnetic field that interacts with the stator's magnetic field, producing torque. This torque causes the rotor to rotate, allowing the motor to perform mechanical work. DC motors are known for their precise speed control, making them ideal for applications requiring variable speed and torque. Furthermore, their relatively simple design leads to easier maintenance and longer operational life, enhancing their appeal across various industries, including robotics, automotive, and consumer electronics.

DC motors are integral to various industrial applications due to their numerous advantages, making them a preferred choice in many sectors. One of the key benefits is their precise speed control, which is essential in processes requiring accuracy. According to a study by the International Journal of Engineering Research and Applications, DC motors with speed control features can enhance productivity in manufacturing by up to 20%. This level of control allows industries such as robotics, conveyor systems, and textile machines to operate more efficiently, reducing waste and improving output quality.

Another significant advantage of DC motors lies in their ease of use and maintenance. A report by the National Electrical Manufacturers Association highlights that the simplicity of DC motor design leads to lower maintenance costs compared to alternative motor types. Industries benefit from lower operational downtime, as DC motors can be easily serviced and repaired. Furthermore, their compact size and lightweight nature allow for flexible integration into various systems, making them ideal for applications in automotive assembly lines and automated guided vehicles. This versatility, combined with reliability and operational efficiency, positions DC motors as a cornerstone technology across many industrial sectors.

| Benefit | Description | Common Applications |

|---|---|---|

| Simple Speed Control | DC motors offer easy speed regulation by varying the voltage applied. | Conveyor systems, fans |

| High Starting Torque | DC motors can provide high torque at startup compared to AC motors. | Electric vehicles, cranes |

| Compact Size | DC motors are relatively smaller and lighter, making them suitable for confined spaces. | Robotics, portable tools |

| Cost-Effective | Generally, DC motors are more affordable than their AC counterparts. | Consumer electronics, appliances |

| Low Maintenance | They require less maintenance compared to other types of motors due to simpler design. | Fans, printers |

| Quick Response | DC motors have a rapid response to control signals, making them ideal for dynamic applications. | Servo systems, robotics |

| Reversible Operation | DC motors can easily reverse direction by changing the polarity of the voltage. | Lift systems, winches |

| Wide Speed Range | They operate efficiently across a broad speed range, offering flexibility in applications. | Packaging machinery, medical devices |

| Smooth Operation | DC motors provide smooth and quiet operation, beneficial in noise-sensitive environments. | Home appliances, office equipment |

| High Efficiency | DC motors are known for their high efficiency, resulting in reduced energy consumption. | HVAC systems, electric bikes |

DC motors have emerged as a pivotal technology in various applications due to their remarkable energy efficiency. According to the U.S. Department of Energy, DC motors can achieve efficiency levels of up to 90%, surpassing many other motor types. This efficiency translates into reduced energy consumption, which is particularly beneficial in applications ranging from automotive to industrial machinery. As energy costs increase, the adoption of DC motors can result in significant savings over time, making them an attractive choice for businesses looking to optimize operations.

In addition to direct energy savings, the inherent controllability of DC motors contributes to their energy efficiency. Research indicates that variable-speed drives can further enhance efficiency by allowing motors to operate at the precise speed required for specific tasks. A report from the International Energy Agency (IEA) suggests that implementing variable-speed drives in motor systems can lead to energy savings of 20% to 50%, emphasizing the importance of integrated motor control technologies. As industries strive for sustainability, the integration of energy-efficient DC motors stands out as a key strategy to reduce carbon footprints and comply with global energy regulations.

This chart illustrates the top 10 benefits of using DC motors across different applications, highlighting their energy efficiency, control simplicity, and other advantages.

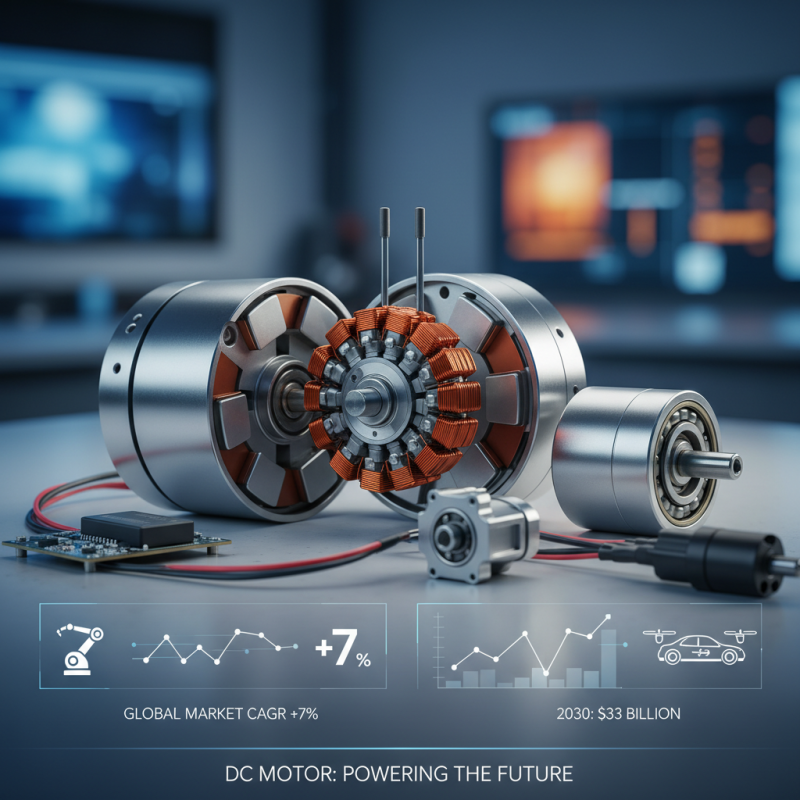

DC motors have established themselves as a versatile and reliable choice across various sectors, including automotive, robotics, and consumer electronics. According to a recent report by Research and Markets, the global DC motor market was valued at approximately $20 billion in 2022 and is expected to grow at a CAGR of 7% through 2030. This growth is driven by the increasing demand for automation and precision control in industrial applications, where the flexibility and efficiency of DC motors play a significant role. Their ability to provide instant torque and maintain a constant speed makes them ideal for use in applications ranging from electric vehicles to automated manufacturing systems.

In the robotics sector, DC motors are pivotal for driving movements and operating actuators. A study from Industry Research shows that the robotics market is projected to reach nearly $200 billion by 2025, with DC motors being a core component in many designs due to their simplicity and ease of control. Their lightweight nature also contributes to energy efficiency, which is particularly beneficial in mobile applications such as drones and electric scooters. Furthermore, the adaptability of DC motors to various control methods allows for enhanced performance, enabling advancements in technology that require high precision and reliability.

The integration of DC motors into modern technology and automation has revolutionized various industries by providing precise control and reliability. These motors are particularly favored in applications requiring steady speed and torque, enhancing efficiency in automated systems. From robotics to manufacturing, the ability to seamlessly adjust motor speed ensures that machines can operate with optimum performance, adapting to varying workloads and reducing energy consumption.

Moreover, DC motors offer compact designs that facilitate easier installation in diverse environments. Their straightforward control mechanisms align well with modern automation protocols, enabling integration with advanced control systems like PLCs (programmable logic controllers) and microcontrollers. This compatibility simplifies the process of automating tasks, leading to higher productivity and reduced operation times.

As industries continue to embrace smart technology, the role of DC motors becomes increasingly essential, forming the backbone of numerous automated processes that drive innovation and economic growth.