In the ever-evolving landscape of modern engineering, the selection of the right motor can significantly impact the success of a project. One of the standout options available to engineers and designers today is the PMDC Motor, known for its impressive efficiency and versatility. PMDC, or Permanent Magnet Direct Current motors, combine the simplicity of design with exceptional performance, making them an ideal choice for a wide range of applications.

As we delve into the top five benefits of incorporating PMDC Motors in your next project, it becomes clear why they have gained popularity in various industries. From their compact size to their reliable torque characteristics, PMDC Motors offer unique advantages that cater to the demands of contemporary design. By understanding these benefits, engineers can make informed decisions that enhance operational efficiency, reduce energy consumption, and ultimately lead to more successful project outcomes.

Whether you are developing a small electronic device or a large industrial system, the role of PMDC Motors is pivotal in driving innovation and performance.

PMDC (Permanent Magnet Direct Current) motors have emerged as a preferred choice for various projects due to their enhanced efficiency. One of the primary advantages of PMDC motors is their ability to maintain high performance with minimal energy consumption. This efficiency is particularly valuable in applications where power supply is limited or where reducing operational costs is a priority. By maximizing output while minimizing energy usage, PMDC motors contribute to more sustainable and cost-effective project outcomes.

Moreover, the simplicity of the design in PMDC motors allows for easier integration into various systems. They require fewer components, which reduces the potential for mechanical failures and maintenance challenges. This straightforward architecture not only improves reliability but also enhances operational efficiency by enabling faster installation and commissioning processes.

As projects increasingly demand high efficiency with lower environmental impact, the adoption of PMDC motors becomes a strategic choice for engineers and designers looking to optimize their designs.

When considering motor options for your next project, PMDC motors stand out not only for their performance but also for their cost-effectiveness across various applications. Their simple design allows for reduced manufacturing costs while maintaining high efficiency. This is particularly beneficial in applications where budget constraints are critical, such as in automotive systems or consumer electronics. By selecting a PMDC motor, developers can minimize initial investments and operational costs, leading to greater overall project feasibility.

Moreover, the low maintenance requirements of PMDC motors further enhance their cost advantages. With fewer components prone to wear and tear compared to other motor types, businesses can save on maintenance expenses and downtime. This reduction in the ongoing operational costs makes PMDC motors an attractive choice for a wide range of applications, from robotics to medical devices. By incorporating PMDC motors, engineers can achieve economically viable solutions while ensuring reliability and longevity in their designs.

The chart below illustrates the top five benefits of using PMDC motors in various applications, highlighting their cost-effectiveness, efficiency, reliability, ease of control, and compact size.

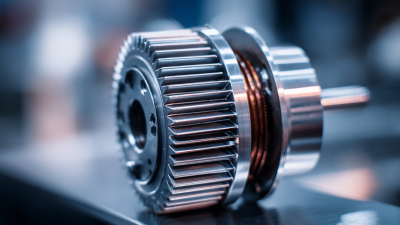

When designing a project, space constraints often challenge engineers and designers. PMDC (Permanent Magnet Direct Current) motors present a compact design that effectively addresses these spatial limitations. Their smaller footprint compared to traditional motors allows for more flexibility in layout and integration, making them ideal for applications in tight environments, such as portable devices or small machinery. This design efficiency not only streamlines the manufacturing process but also enhances the overall aesthetics of the final product.

Furthermore, the reduced size of PMDC motors does not compromise performance. In fact, their lightweight structure can lead to an overall decrease in the total weight of the assembly, which is particularly beneficial in industries like automotive and aerospace where weight savings are critical. The ability to incorporate these motors without the need for bulky housing further simplifies the design and can lead to cost savings in both material and production. Overall, the integration of PMDC motors can result in innovative, space-efficient solutions that can meet the demands of contemporary engineering challenges.

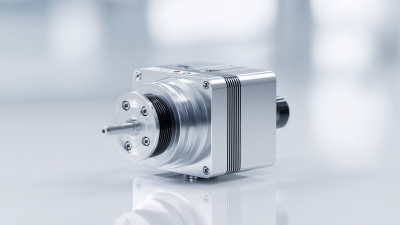

When embarking on a new project, the need for versatile performance in your drive systems cannot be overstated. PMDC (Permanent Magnet Direct Current) motors stand out for their ability to be customized for a variety of applications. This adaptability means that whether you're working on robotics, automotive systems, or home appliances, PMDC motors can be tailored to meet specific speed, torque, and control requirements, ensuring optimal performance for your unique design.

Customization options extend beyond just the physical aspects of the motor. By modifying parameters such as the winding configurations, magnet materials, and even the electronic controllers, engineers can achieve precise performance characteristics that align perfectly with project goals. This flexibility not only enhances the efficiency of the final product but also allows for innovations that can set your project apart in a competitive market. With PMDC motors, the path to a high-performing and versatile solution is well within reach.

In engineering projects, the reliability and longevity of the motors used are paramount, particularly in demanding environments.

PMDC (Permanent Magnet Direct Current) motors are increasingly favored for their robust performance, which significantly reduces maintenance needs.

For instance, recent innovations in the industry showcase how advanced motor technologies, including modular options for speed regulation, contribute to operational efficiency.

This is particularly evident in industrial applications, where the transition from older DC motors to improved models leads to enhanced reliability and reduced downtime.

Moreover, the implementation of PMDC motors can also yield substantial long-term benefits. Their compact design and efficiency not only facilitate easier integration into various projects but also result in lower operational costs over time.

By employing such motors, engineers can ensure that their systems experience fewer failures and require less frequent servicing, ultimately extending the overall lifespan of the machinery involved.

In a landscape where performance and durability are critical, PMDC motors stand out as a superior choice, promising a robust solution for future engineering endeavors.