In the realm of electric motors, the "Brushless DC Motor Drive" stands out for its efficiency and performance. Renowned expert Dr. Alex Chen states, "Choosing the right drive is crucial for optimal motor function." This underscores the importance of selecting the best options available in the market today.

Brushless DC Motor Drives eliminate the drawbacks of traditional motors. They provide higher efficiency, reduced maintenance, and quieter operations. In various industries, these motors have become indispensable. However, not every drive is created equal. It's vital to weigh options carefully.

Many factors influence the performance of a Brushless DC Motor Drive. While some drives excel in efficiency, others may falter in specific applications. This leads to potential pitfalls if not considered. The landscape is evolving, but many questions remain. Are you utilizing the best technology for your needs? These considerations warrant reflection for improved outcomes.

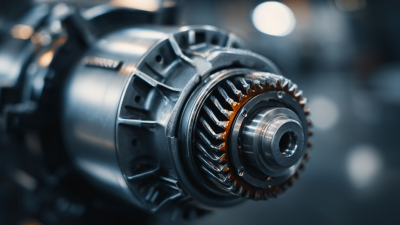

Brushless DC motors (BLDC) have gained immense popularity due to their numerous advantages. One major benefit is their high efficiency. Unlike brushed motors, BLDC motors do not have brushes that create friction. This leads to less energy loss and improved overall performance. With continuous advancements in technology, many applications are now leveraging this efficiency.

Another critical advantage is longevity. Without brushes, BLDC motors have a longer lifespan. They require less maintenance, making them ideal for various industries. Additionally, they operate more quietly than traditional motors, which is beneficial in noise-sensitive environments. However, it’s important to consider that the initial cost may be higher than brushed counterparts.

BLDC motors also offer precise control. Their speed and torque can be adjusted easily, allowing for better adaptability in different applications. Nonetheless, this can also lead to complexity. The control systems can be intricate and sometimes challenging to set up properly. Innovation comes with its own set of challenges, and this is a point of reflection for many engineers considering BLDC motors.

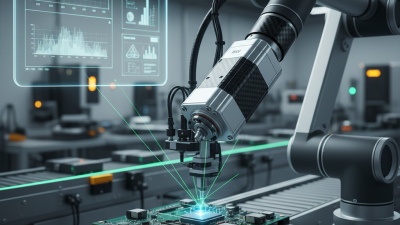

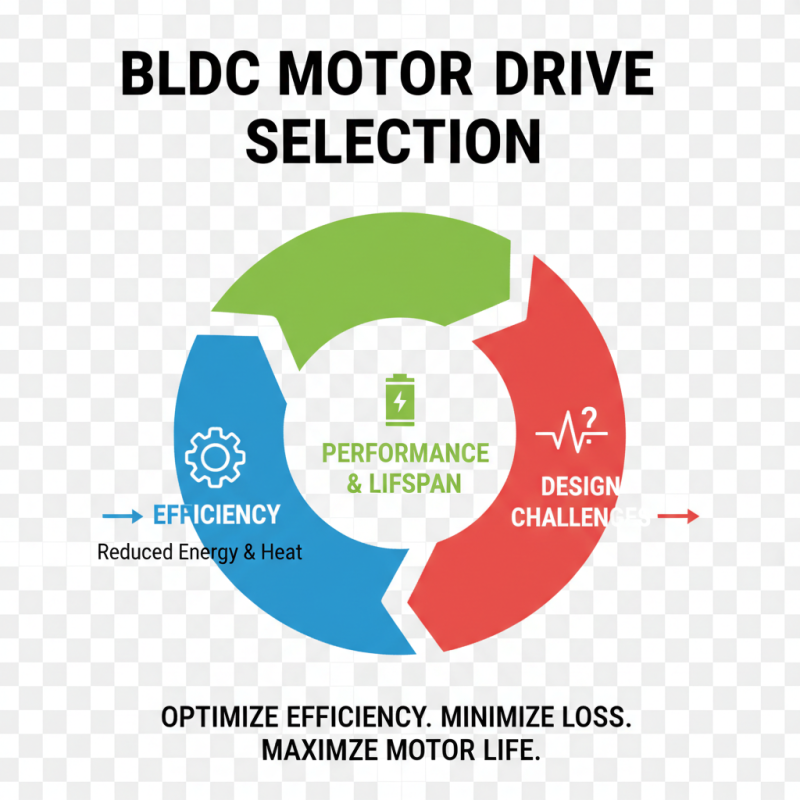

When selecting a brushless DC motor drive, several key factors come into play. Efficiency is often the top priority. An efficient drive reduces energy consumption and heat generation. This not only enhances performance but also extends the lifespan of the motor. However, achieving high efficiency can be challenging. Poor design choices can lead to energy loss, which must be carefully analyzed.

Performance is another critical aspect. It involves torque, speed control, and response time. High torque at low speeds is essential in many applications. If the drive cannot handle quick changes well, operations may suffer. Additionally, noise levels can impact overall performance. A quieter drive often indicates better engineering, but it might also reflect compromises in other areas.

Compatibility with existing systems is sometimes overlooked. You must ensure that the drive matches the power supply, interface, and operating environment. Mismatched components can create inefficiencies or even damage the system. Evaluating the compatibility of various features, like communication protocols, is essential. Failing to do so may lead to unforeseen issues later on.

When assessing brushless DC motor drive options, efficiency often stands out as a critical factor. Different drives offer varying levels of efficiency. Some controllers deliver better performance at low speeds, while others shine at high speeds. Understanding how these drives behave under different conditions helps users select the right option for their needs.

Comparative analysis reveals that while one drive may excel in terms of energy consumption, it may fall short in thermal management. Heat generation is a common issue with high-performance drives. Users should consider the implications of heat on system longevity and reliability. Choosing a drive with efficient cooling may lead to better overall performance, despite a slightly lower efficiency rating.

Another aspect to ponder is control complexity. Some efficient drives require intricate programming and setup. This might hinder quick deployment in time-sensitive projects. Balancing ease of use with performance needs is essential for optimal operations. Each drive has its pros and cons, requiring careful consideration to meet specific application requirements.

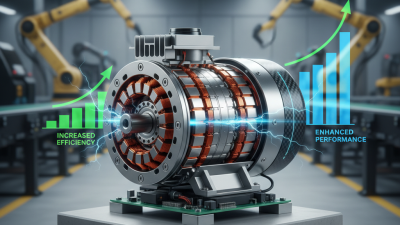

When evaluating brushless DC (BLDC) motor drives, performance metrics are crucial. Efficiency is often a top priority. Industry data shows that high-quality BLDC drives can achieve efficiency rates over 90%. This can significantly lower operational costs in applications like electric vehicles or robotics. However, factors like load conditions and ambient temperature need careful consideration.

Another important metric is the start-up torque. Many BLDC drives provide sufficient torque across various speeds, which is vital in dynamic applications. For instance, a recent report indicated that BLDC motors can deliver up to 300% of rated torque at startup. This capability, while impressive, can lead to overheating if not managed correctly.

Control precision also plays a significant role in performance. Many systems aim for response times under 10 milliseconds, which enhances smooth operation. Nevertheless, achieving tight control can be challenging. Programming and tuning a BLDC drive demands experience and fine-tuning. Many engineers find that while theoretical models suggest high performance, real-world results often differ. Debugging unpredictable behavior requires time and resources.

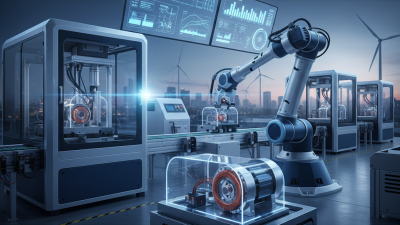

The future of brushless DC (BLDC) motor technology shows promising trends in efficiency and innovation. As industries push for greener solutions, BLDC motors are stepping up. Data from recent industry reports indicate a projected growth rate of 8% in this sector by 2026. This growth correlates with rising demands for energy-efficient systems across various applications.

Advancements in semiconductor technology are enhancing BLDC drives. These technologies can reduce energy loss significantly. Reports show a 10-15% efficiency gain compared to traditional motors. This increase is vital in industries where energy consumption heavily impacts costs. However, integration challenges remain. Some designs do not adapt easily. Manufacturers must balance efficiency with practical manufacturing processes.

Another area of focus is the integration of IoT in BLDC technology. IoT can provide real-time monitoring of motor performance. This allows for predictive maintenance and improved longevity. Nevertheless, this integration poses cybersecurity risks that can't be overlooked. Industry experts stress the importance of managing these vulnerabilities as the technology evolves. These developments highlight the dual path of opportunity and challenge in brushless motor technology.

| Drive Type | Efficiency (%) | Max Torque (Nm) | Operating Voltage (V) | Key Features |

|---|---|---|---|---|

| Sensorless Drive | 90 | 1.5 | 24 | Compact Size, Cost-effective |

| Closed-Loop Drive | 95 | 2.0 | 48 | High Precision, Improved Control |

| Digital Drive | 92 | 1.8 | 36 | Smart Features, User-Friendly Interface |

| Integrated Drive | 93 | 1.2 | 12 | Space-Saving Design, Ease of Use |