Brushless DC electric motors (BLDC) are revolutionizing various industries. Their efficiency and reliability make them a popular choice in modern applications. These motors are widely used in electric vehicles, drones, and household appliances. Their design eliminates brushes, resulting in less wear and a longer lifespan.

One significant benefit of brushless DC electric motors is their high power-to-weight ratio. This feature allows users to achieve better performance with less energy consumption. Additionally, they operate more quietly compared to brushed motors, making them suitable for sensitive environments. However, there are challenges to consider. The cost of BLDC motors can be higher than traditional motors. This could be a setback for budget-conscious projects.

Despite these concerns, many industries are embracing brushless DC electric motors. The technology continues to evolve, leading to better efficiency and lower operational costs. Designers and engineers must continually evaluate their choices, balancing performance against budget constraints. In this article, we will explore the different types of brushless DC electric motors available and their specific benefits, offering valuable insights for anyone considering this technology.

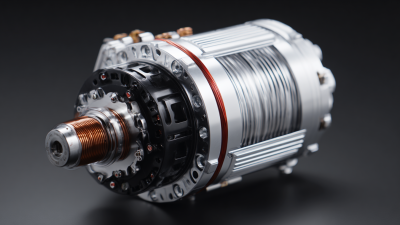

Brushless DC electric motors come in various types, each with specific benefits. The main types include sensorless brushless motors, brushed motors, and permanent magnet motors. Sensorless brushless motors rely on back EMF for operation. They are simple and cost-effective but might struggle at low speeds.

Permanent magnet motors offer high efficiency and compact designs. They are suitable for high-performance applications like drones and electric vehicles. However, these motors can be pricier and often require advanced control mechanisms.

When choosing a type, consider your application needs carefully. Think about the environment, load requirements, and space constraints. Sometimes, a simpler motor might perform just as well.

Tips: Always account for potential heat generation. Overheating can lead to inefficiency. Test in a controlled setting before full-scale use. Lastly, be aware that some types may have limited availability. Explore your sources thoroughly.

Brushless DC electric motors are gaining popularity for various applications. One key advantage is their higher efficiency. Unlike traditional motors, brushless designs do not have friction from brushes. This leads to less energy loss and longer battery life in portable devices.

Another benefit is the reduced maintenance. Traditional motors often require brush replacement. Brushless motors, however, can run for years without significant wear. This lower maintenance can save time and money for users.

Tips: When selecting a brushless motor, consider the application needs carefully. Think about speed, torque, and required durability. Not all brushless motors are created equal. Conducting thorough research may help you find the best fit for your project. Also, be aware that while brushless motors may have a higher initial cost, their longevity and efficiency could lead to savings in the long run.

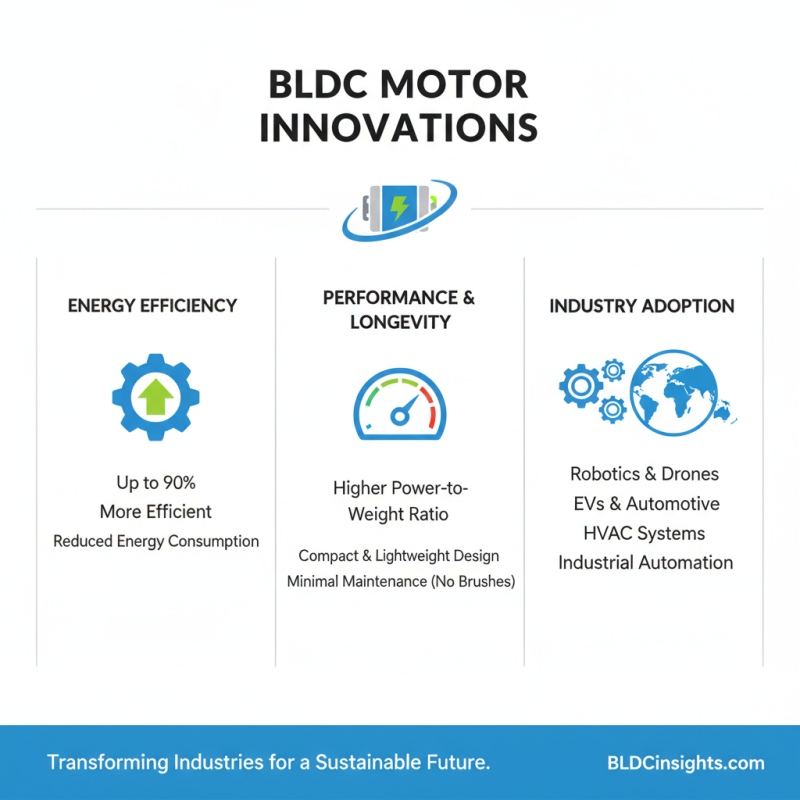

Brushless DC electric motors have gained immense popularity across various applications. Their efficiency ratings significantly impact power consumption and performance metrics. According to a report by the International Energy Agency, these motors can achieve efficiencies exceeding 90%. This high efficiency leads to substantial energy savings over time.

In practical scenarios, brushless motors often deliver better torque-to-weight ratios. They perform well in demanding applications like robotics and electric vehicles. For instance, in electric cars, the savings in power consumption can translate to extended range. Yet, some challenges persist. The initial cost is generally higher than that of brushed motors. Users may find the installation process complex, necessitating trained personnel.

Performance metrics are critical. Torque response is often instantaneous, enhancing operational efficiency. In real-world applications, variability in performance can occur due to thermal effects and load conditions. The benefits are clear, yet achieving optimal performance requires careful consideration and ongoing adjustments. Understanding these nuances can lead to better long-term outcomes.

| Motor Type | Efficiency (%) | Power Consumption (W) | Torque (Nm) | Applications |

|---|---|---|---|---|

| Inner Rotor | 85 - 95 | 100 - 500 | 0.5 - 5 | Robotics, HVAC |

| Outer Rotor | 90 - 98 | 50 - 300 | 1 - 3 | Electric Vehicles, Drones |

| Slotless | 80 - 90 | 75 - 400 | 0.2 - 4 | Power Tools, Fans |

| Coreless | 70 - 85 | 10 - 150 | 0.1 - 2 | Medical Devices, Small Appliances |

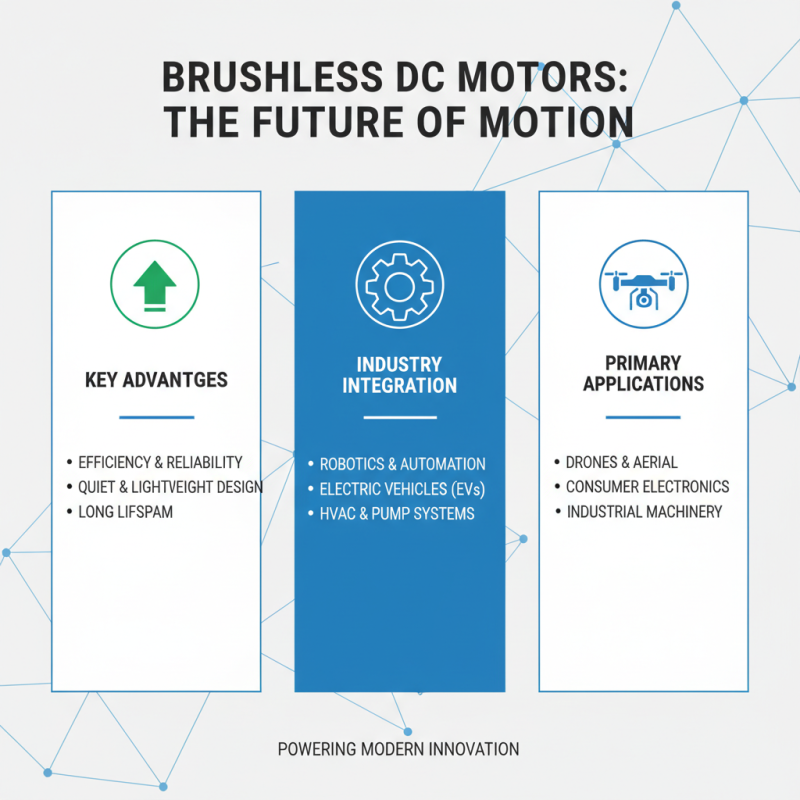

Brushless DC motors have become integral in various industries. Their efficiency and reliability are unmatched. These motors are quiet and lightweight, making them perfect for modern applications. From robotics to automotive, their impact is profound. They power drones, electric vehicles, and HVAC systems.

In robotics, brushless motors enable precise movements. They help in tasks that require accuracy. These motors are often used in manufacturing lines. Here, they drive conveyor belts and robotic arms. They improve production rates significantly. However, the technology is not without challenges. The initial cost can be high, affecting budgets.

Furthermore, maintenance can be tricky. While they require less maintenance than brushed motors, issues can arise. Overheating can occur if not monitored. Industries need to invest in good thermoregulation systems. This ensures longevity and efficiency. The benefits of brushless motors are clear. However, organizations must be mindful of these limitations to harness their potential effectively.

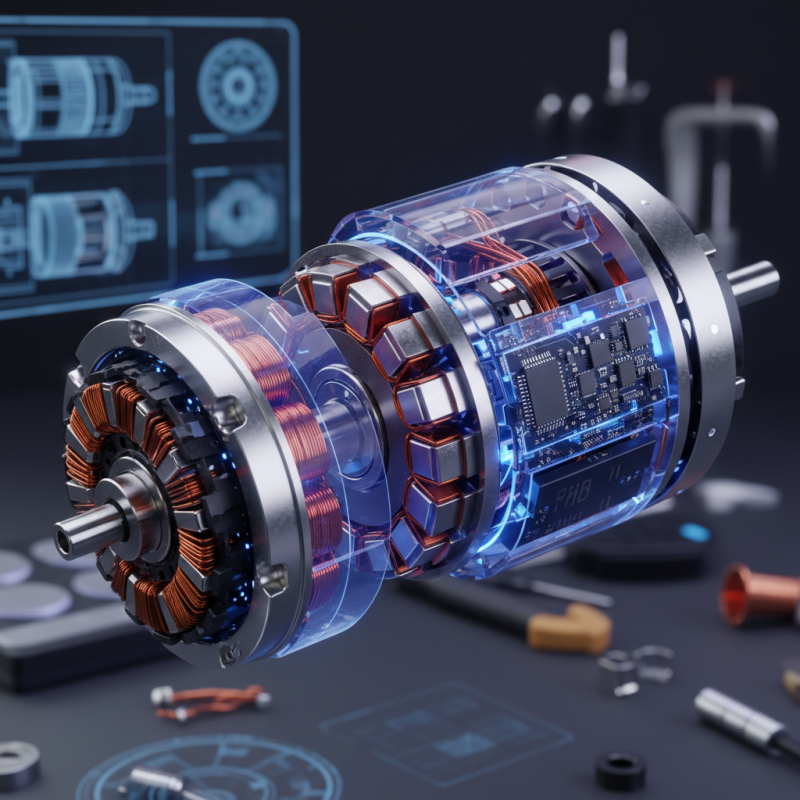

Innovations in brushless DC electric motors are transforming how we think about energy efficiency and performance. These motors, which rely on electronic controllers, offer higher efficiency and reduced maintenance compared to traditional counterparts. The latest designs focus on lightweight materials and compact structures, which allow for greater power-to-weight ratios. Many industries are embracing these advancements to meet their evolving needs.

Emerging technologies like artificial intelligence and advanced sensors are shaping the future of motor design. Incorporating smart interfaces can enhance performance and facilitate predictive maintenance. However, challenges remain in terms of cost and complexity. Not all manufacturers can easily adapt to these innovations. As designs become more intricate, so does the knowledge required to implement and maintain them effectively.

Sustainability is another hot topic. The push for greener technologies is driving research into eco-friendly materials and recycling processes for motor components. While the benefits are clear, the path forward is riddled with hurdles. Businesses must balance performance, cost, and environmental impact in their decision-making. The future of brushless motors looks promising, but careful consideration is required to fully realize its potential.