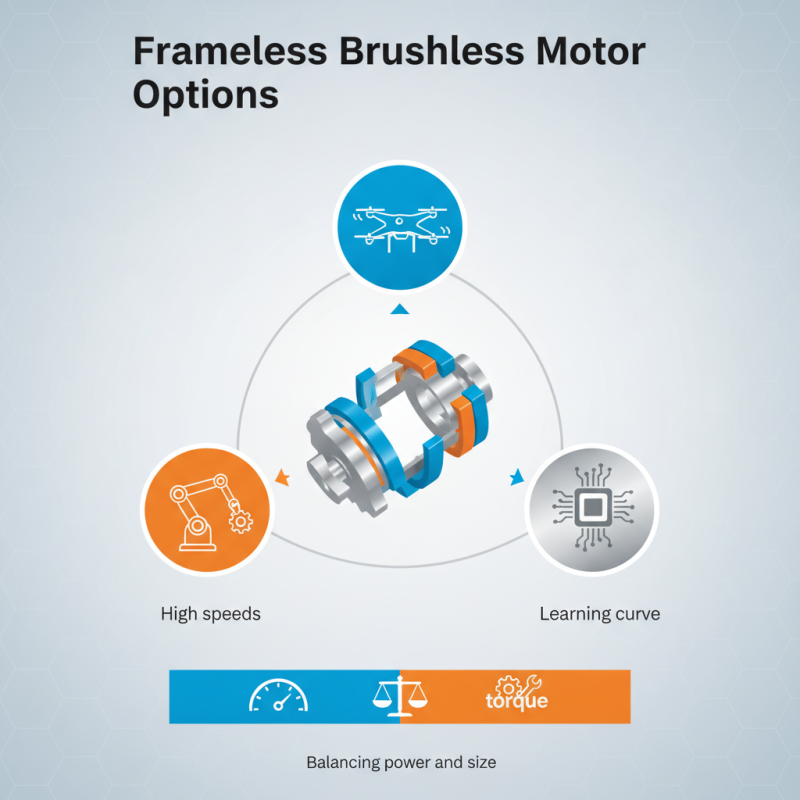

Finding the right motor for your project can be challenging. The Frameless Brushless Motor stands out for its versatility and efficiency. It is lighter and more compact than traditional motors, making it an excellent choice for various applications. You may find these motors ideal for drones, robotics, and more.

However, not every frameless brushless motor is created equal. Performance can vary greatly between models. Some may offer high speeds, while others focus on torque. It’s essential to consider what you need before making a decision.

Choosing the best option requires some reflection. Understand your project requirements clearly. Balancing power and size is critical. There may be a learning curve when experimenting with these motors. Embrace this process to find the perfect fit for your needs.

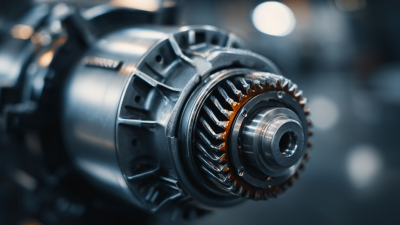

Frameless brushless motors are gaining traction in various industries. Understanding their core advantages can help project managers make informed decisions. These motors have no traditional frame, leading to significant weight reductions. According to a 2023 report, frameless designs can save up to 30% in weight compared to traditional designs.

One major benefit is the efficiency, especially in high-performance applications. A study highlighted that frameless brushless motors can achieve efficiency ratings above 90%. This efficiency translates into longer operational times and less energy consumption. These motors are also quieter, reducing noise pollution in sensitive environments. However, installation can be tricky. The absence of a frame means careful alignment is crucial.

Tips: Ensure proper alignment during installation to avoid uneven wear. Choose a motor based on your specific needs; not all frameless motors are equal. Consider the heat generation in high-output scenarios, which can affect performance over time. Overall, while frameless brushless motors offer many advantages, they require thoughtful planning and execution.

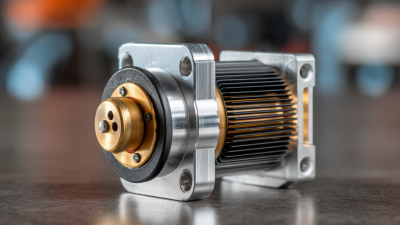

When selecting frameless brushless motors, understanding key specifications is crucial. One major factor is the motor’s size and weight. A lighter motor enhances efficiency, which is vital for robotics and drone applications. Reports indicate that weight reductions of just 10% can improve energy use by up to 15%.

Another important aspect is power output. Measuring in watts, higher ratings typically yield better performance. Most projects require an optimal balance between power and efficiency. Using data from engineering studies suggests that a motor rated at 1,000 watts will often outperform one at 500 watts in demanding environments. Yet, over-specifying power can lead to unnecessary heat generation and reduced lifespan.

Additionally, consider the operating voltage. Most frameless brushless motors operate at 12 to 48 volts. However, higher voltage can enhance torque and speed capabilities. Shorter life spans are often noted at extreme voltage levels. Seek a middle ground to ensure reliability and longevity. Understanding these specifications will aid in choosing the right motor for your specific project needs.

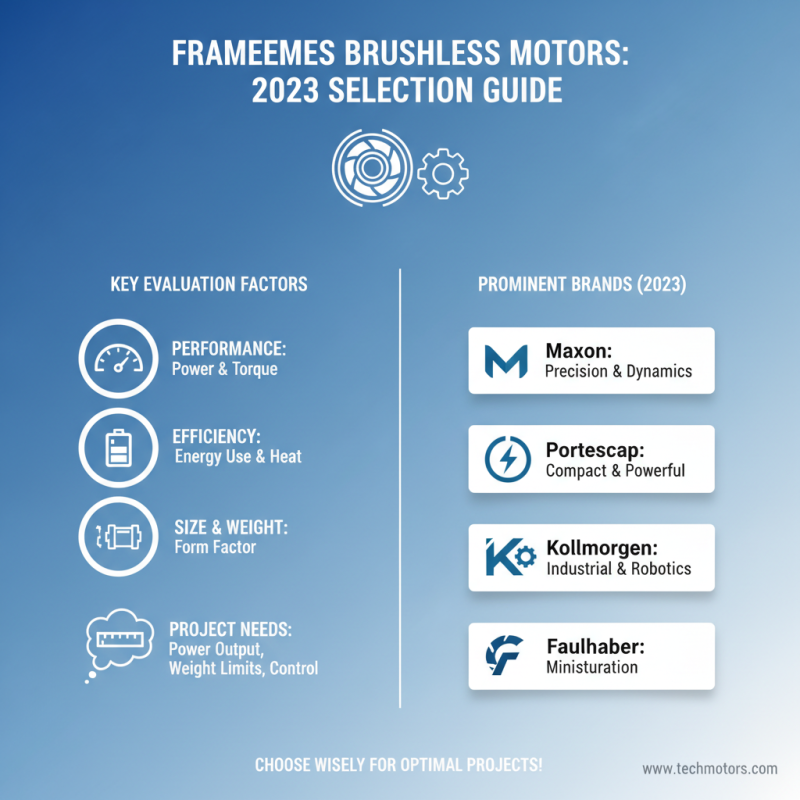

Selecting the right frameless brushless motor for your projects can be challenging. In 2023, there are several prominent brands to consider. Each brand offers unique features. Performance, efficiency, and size are key factors to evaluate. Consider your project's specific needs, like power output and weight constraints.

When exploring different models, pay attention to torque ratings and RPM specifications. These metrics will directly impact your project’s performance. High torque is essential for demanding applications. Also, ensure that the motor’s size fits within your design. Sometimes, the most powerful motor may not be the best choice if it doesn't integrate seamlessly.

**Tips:** Look at user reviews on forums to gain real-world insights. Sometimes, a motor may seem perfect on paper but underperform in practice. Test the motors in simulations or smaller setups before a full installation. Remember, a little experimentation goes a long way. It's okay to make mistakes; they often lead to the best solutions.

Frameless brushless motors are increasingly used in robotics and UAVs. These motors provide high efficiency and compact designs. Their lightweight nature allows for innovative applications in various projects. In robotics, they enable precise movements and responsive controls. Often, they serve in robotic arms and drones, enhancing dexterity and stability.

However, integrating these motors is not without challenges. The setup can be complex, requiring careful alignment and calibration. Additionally, thermal management is crucial. Excess heat can affect performance and lead to failures. Users must invest time in learning and testing configurations. This trial-and-error approach can be frustrating but ultimately rewarding.

In UAVs, frameless brushless motors help achieve high thrust-to-weight ratios. This is vital for flight performance. They support various payloads while maintaining agility. Yet, the reliance on optimal power systems poses risks. Battery life and motor efficiency directly impact flight dynamics. These factors must be balanced carefully to ensure success.

Frameless brushless motors have gained traction in diverse applications due to their unique design. Compared to traditional motors, they boast a lighter weight and enhanced efficiency. This efficiency can reach up to 90% in certain configurations. In contrast, traditional motors typically operate at around 70-80%, leading to considerable energy losses.

The comparative performance shows significant differences in thermal management. Frameless motors generate less heat due to their design, improving reliability and lifespan. A 2022 industry report highlighted that users experienced a 30% reduction in overheating incidents with frameless options. However, this technology may require more specialized control systems. A gap in understanding these controls exists, which can deter some users.

Noise emissions are another factor to consider. Frameless motors usually operate quieter, with noise levels dropping by as much as 20 decibels compared to traditional models. Despite these advantages, the initial cost can be a hurdle. Users must weigh short-term expenses against long-term benefits. Research indicates that organizations may recover their investment in as little as two years, depending on usage. It’s a complex decision that requires careful analysis.