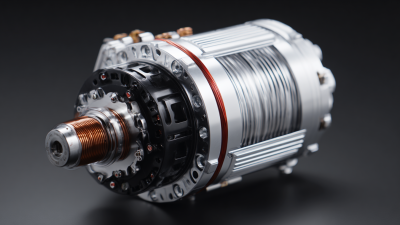

In the ever-evolving world of engineering and robotics, the "High Torque Brushless DC Motor" stands out. This powerful component has become essential for various projects. Experts in the field recognize its importance. Dr. Sarah Thompson, a leading expert in motor technology, once said, “High Torque Brushless DC Motors empower innovation in countless applications.”

These motors are known for their efficiency and reliability. They deliver high torque performance in compact designs. This makes them ideal for applications like drones, electric vehicles, and industrial machinery. However, not all high torque motors are created equal. Choosing the right one can be challenging and requires careful consideration.

In recent years, advancements in materials and technology have improved performance. Yet, some products still fall short of expectations. Users often face issues like overheating or insufficient torque. It's crucial to conduct thorough research and testing. The right choice can lead to significant benefits in your projects, while a poor decision may hinder progress.

Brushless DC motors are becoming popular in various projects. They function without brushes, which minimizes wear and tear. This design leads to longer lifespans compared to brushed motors. They are efficient and can provide high torque at high speeds. Many hobbyists and engineers favor them for robotics and automation tasks.

One major advantage is their precise control. This makes them ideal for applications requiring accurate positioning. They run quieter, which is important in environments where noise matters. However, not all projects require such specific features. Sometimes, simplicity is more practical. If budget constraints exist, other options may be worth considering.

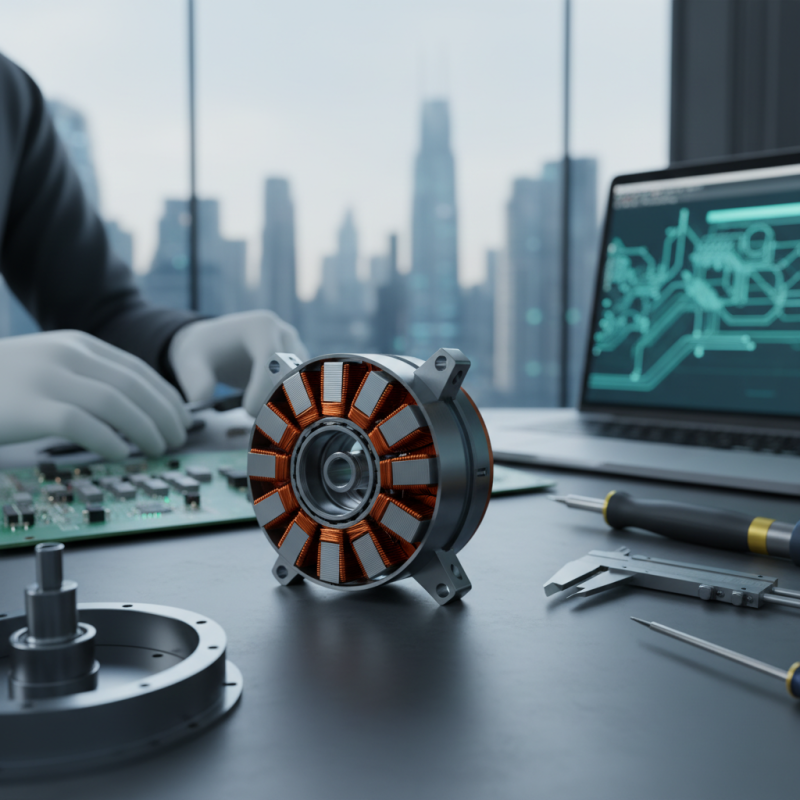

These motors also require electronic speed controllers, adding complexity to your project. This additional component can lead to challenges in setup and integration. Some users may find it frustrating. Therefore, understanding the full scope of requirements is essential. Balancing performance and ease of use is a key consideration when selecting a motor for your application.

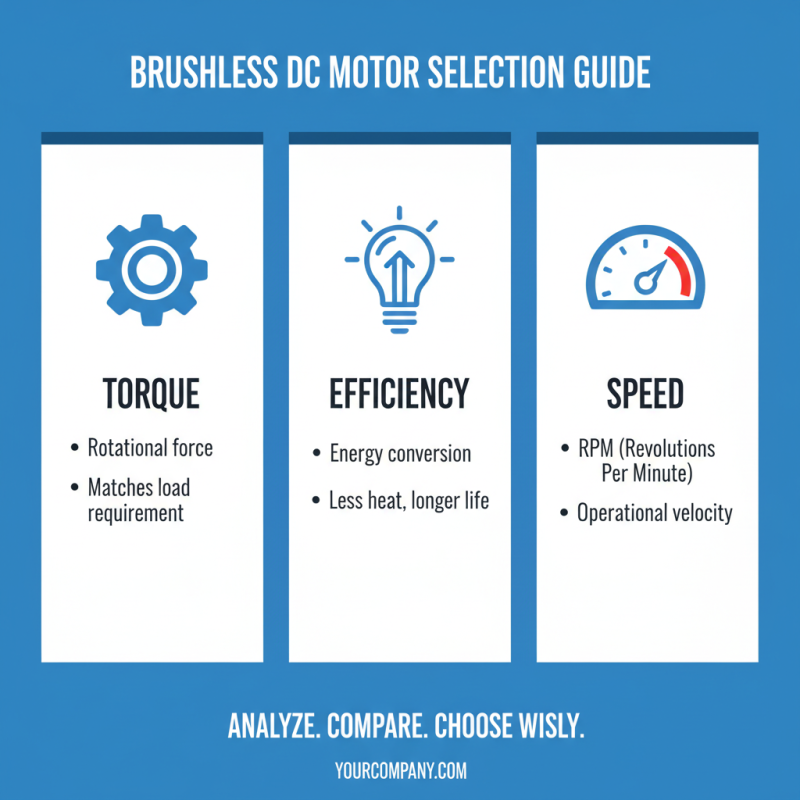

When choosing a high torque brushless DC motor, several factors come into play. First, consider the torque requirements of your project. High torque motors are essential for heavy loads or demanding applications. Check the motor's specifications to ensure it meets your needs.

Power rating is another key element. A motor with a higher power rating provides more torque. However, this may come at a higher cost. Balance your budget with performance needs.

Tips: Always calculate the load you expect to use. This helps avoid overloading the motor.

Efficiency matters too. Look for motors with high efficiency ratings. They reduce energy consumption and heat generation. This increases longevity.

Tips: Inspect the cooling options available with your motor. Cooling systems can improve performance significantly.

Don't forget the size and weight of the motor. A larger motor might provide more torque but could complicate installations. Assess the overall dimensions to fit your design.

Remember, sometimes the best choice may involve trade-offs. Evaluate your specific project needs versus available options. Be flexible, and you might discover the perfect fit for your application.

| Model | Rated Torque (Nm) | Voltage (V) | No-load Speed (RPM) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 10.5 | 24 | 3000 | 90 | 1.5 |

| Model B | 15.0 | 36 | 4000 | 92 | 2.0 |

| Model C | 20.0 | 48 | 3500 | 88 | 2.5 |

| Model D | 25.0 | 60 | 5000 | 95 | 3.0 |

When exploring brushless DC motors for your projects, high torque options stand out. They are widely used in robotics, electric vehicles, and automation. In 2026, several key models promise improved efficiency and performance. These motors can deliver substantial power while maintaining compact sizes. However, selecting the right motor involves more than just torque specifications.

Consider the various applications that high torque motors serve. For instance, in robotics, precise control is essential. High torque motors help achieve intricate movements, allowing robots to perform tasks with finesse. Electric vehicles also benefit from these motors, offering better acceleration and reduced energy consumption. Yet, users must evaluate factors like weight, power supply compatibility, and cooling requirements.

It can be tempting to choose the highest torque rated motors. However, ease of integration and control system compatibility must be assessed. Testing different motors in real-world scenarios reveals performance inconsistencies. Evaluating responsiveness and heat generation during operation is crucial. Ultimately, understanding each motor's strengths and weaknesses ensures an effective choice for your specific needs.

When choosing a brushless DC motor, performance ratings are crucial. They determine how well the motor will handle your specific project needs. Factors such as torque, efficiency, and speed must be compared. Analyzing these performance ratings allows for informed decisions.

Tips: Always consider the application. A motor suited for one use might underperform in another. High torque is great for heavy loads, while higher RPM is better for speed-focused projects.

It is vital to review multiple sources during your research. Not all ratings are the same. Real-world performance can vary significantly from specifications. Creating a shortlist of potential motors can help streamline your analysis. Seek detailed comparisons and user reviews to gauge true capabilities. This information can highlight strengths and weaknesses in various environments.

Integrating high torque brushless DC motors into your projects can significantly enhance performance. According to recent industry reports, these motors can deliver torque levels exceeding 1 Nm in compact designs. This feature makes them ideal for applications like robotics and electric vehicles.

When selecting a motor, pay attention to parameters like efficiency and thermal performance. Research shows that optimal efficiency often peaks around 85% for quality brushless DC motors. Keep in mind that achieving this efficiency can require careful design choices related to cooling solutions. Overheating can lead to reduced lifespan and performance. The ideal setup may not be straightforward, and trial and error are common.

Installation considerations also matter. Ensure that the motor controller matches your motor’s specifications. Mismatched systems can lead to frustrating performance issues. Companies report that improperly configured systems can result in torque drop of up to 30%. Thorough testing and adjustment are crucial. Your approach to integration can make or break your project’s success. Take the time to consider each aspect before proceeding.