In the fast-evolving world of industrial automation, the significance of selecting the right equipment cannot be overstated, and the choice of motor is paramount. Industrial Brushless Motors have emerged as a front-runner in the quest for efficiency, durability, and performance, making them increasingly popular across various sectors. As technologies advance, understanding which models stand out in 2023 becomes essential for professionals seeking optimal performance. According to Dr. Emily Wang, an industry expert and a leading engineer at Tech Innovations Corp., "The transition to brushless motors not only offers enhanced reliability but also ensures significant energy savings in industrial applications.”

In this critical landscape, identifying the best Industrial Brushless Motors requires an analysis of factors such as torque, speed, size, and energy efficiency. The right motor can directly influence productivity, reduce maintenance costs, and contribute to a more sustainable operational model. As we delve into the top picks for 2023, these motors not only represent advancements in engineering but also reflect the industry’s commitment to innovating solutions that meet the growing demands of modern manufacturing processes. With insights from experts like Dr. Wang, this guide aims to equip decision-makers with the knowledge to choose the most suitable options for their specific needs.

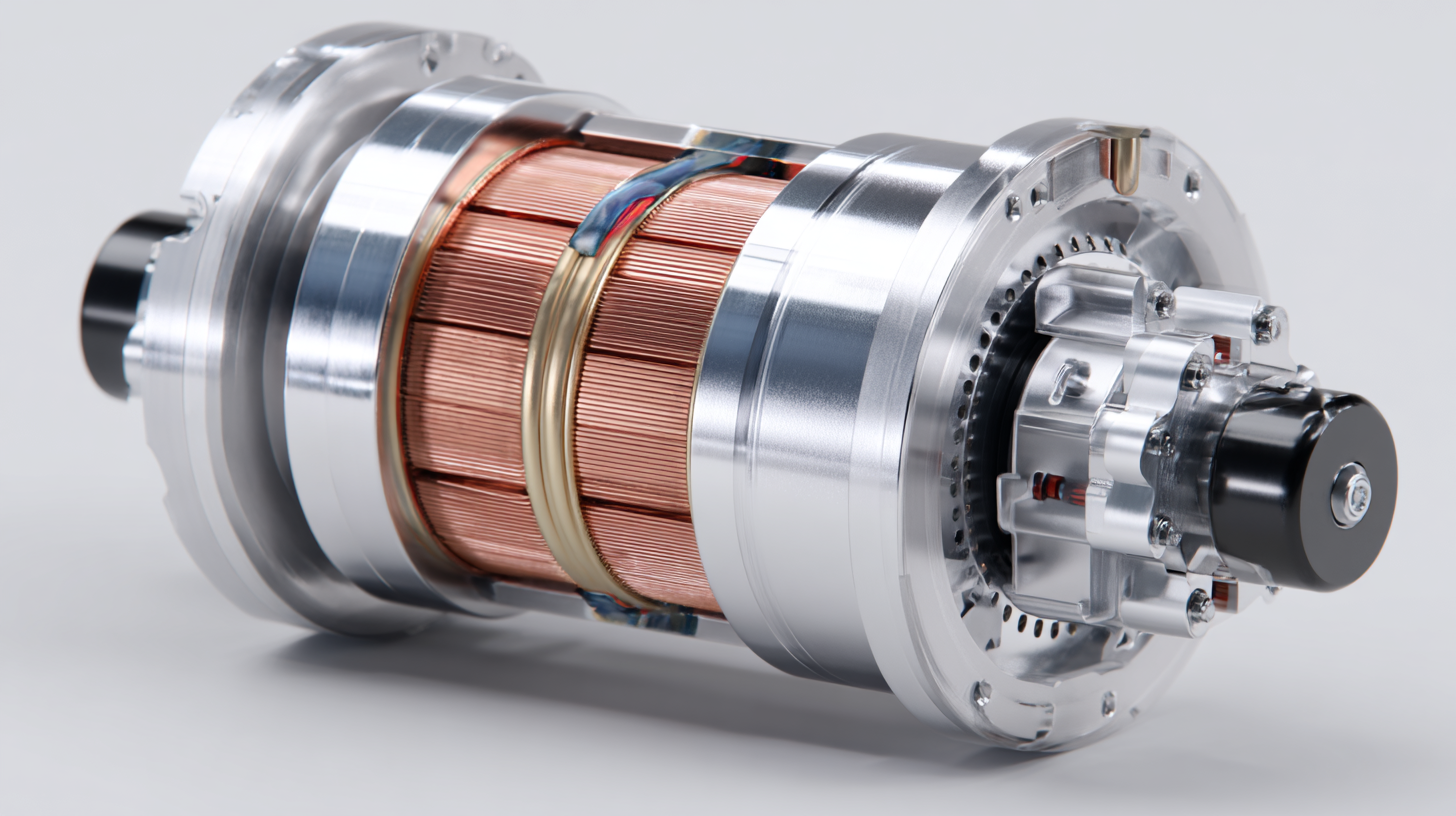

When selecting industrial brushless motors in 2023, certain features can significantly enhance performance and reliability. Firstly, consider the motor's efficiency rating. High-efficiency models reduce energy consumption and operational costs while providing consistent performance over time. Look for motors that integrate advanced algorithms for better speed control and torque management. These features ensure that the motor adapts to various load conditions, maintaining optimal performance across applications.

Another critical feature is thermal management. Effective heat dissipation mechanisms, such as integrated cooling systems, prevent overheating and prolong motor life. Additionally, motors with durable, weather-resistant enclosures are ideal for harsh industrial environments, ensuring that they withstand dust, moisture, and temperature fluctuations.

Tips for selecting the right motor include reviewing the manufacturer's specifications and performance data to align the motor's capabilities with your application requirements. It's also beneficial to consider upgradeability, ensuring that the motor can be easily integrated with existing systems or enhanced with new technologies as they emerge in the industry. By focusing on these key features, you can optimize your investment in industrial brushless motors for exceptional performance and longevity in 2023.

The global brushless motor market is witnessing significant growth, driven by rising demand across various industrial applications. By 2035, the brushless DC motor market is anticipated to increase from an estimated USD 22.22 billion in 2025 to about USD 43.44 billion, with a remarkable compound annual growth rate (CAGR) of 11.63%. This growth highlights the continuous innovation and adoption of brushless motor technology, particularly in power tools and electric vehicles, where efficiency and performance are paramount.

A comparative analysis among leading brands reveals key differentiators in performance metrics and application relevance. The brushless motor power tools segment alone is projected to grow from USD 13.40 billion in 2024 to USD 25.05 billion by 2033. This surge is largely attributed to advancements in industrial automation and enhanced product functional capabilities, positioning brushless motors as the preferred choice for modern power tools. As manufacturers strive to meet the evolving market demands, it is crucial for stakeholders to assess the competitive landscape and investment opportunities within this rapidly expanding sector.

| Motor Type | Power Rating (kW) | Voltage (V) | Speed (RPM) | Efficiency (%) | Torque (Nm) |

|---|---|---|---|---|---|

| BLDC Motor A | 5 | 480 | 3000 | 90 | 15 |

| BLDC Motor B | 7.5 | 400 | 4000 | 92 | 18 |

| BLDC Motor C | 3 | 220 | 2500 | 88 | 10 |

| BLDC Motor D | 10 | 600 | 3000 | 94 | 20 |

| BLDC Motor E | 2 | 110 | 3500 | 85 | 8 |

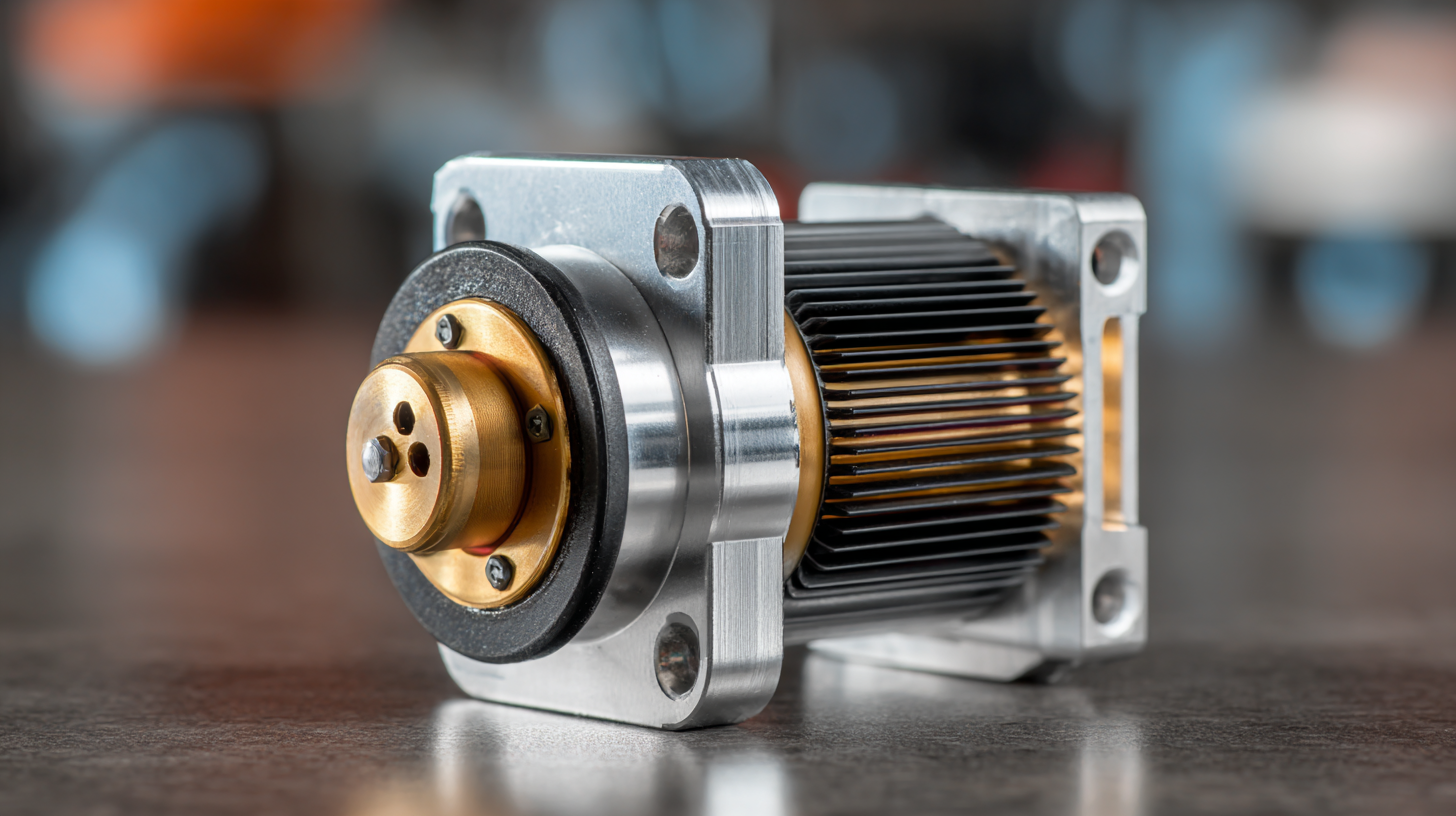

When selecting the right brushless motor for industrial applications, efficiency is paramount. One of the first considerations should be the motor's specifications, such as voltage, current, and power rating. These parameters not only determine the compatibility with your existing system but also influence the overall performance and energy consumption. Additionally, understanding the motor's torque characteristics and operating speed is crucial; a motor that can deliver high torque at lower speeds may be more suitable for specific tasks that require precision and control.

Another essential factor to consider is the cooling mechanism of the brushless motor. Adequate heat dissipation ensures optimal performance and longevity, especially in high-demand scenarios. Look for motors with built-in cooling features or those that can be easily integrated into a cooling system. Furthermore, assessing the environmental conditions where the motor will be deployed, such as atmosphere, temperature, and potential exposure to contaminants, is essential to ensure that the motor can withstand these challenges and maintain efficiency over time.

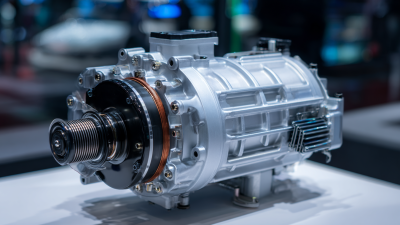

In 2023, the landscape of industrial brushless motors has been significantly transformed by innovative technologies that enhance performance and efficiency. Leading manufacturers have developed new algorithms and control systems that optimize torque delivery and reduce energy consumption, allowing these motors to operate at peak performance even under varying loads. Moreover, advancements in materials such as improved magnets and heat-resistant components have led to lighter and more durable motors, which cater to the demanding needs of modern industry.

When selecting an industrial brushless motor, it is essential to consider its application environment. For instance, if the motor will operate in high-temperature settings, look for models designed with specialized cooling mechanisms. Additionally, utilizing integrated smart controls can facilitate real-time monitoring of performance metrics, thereby enabling proactive maintenance and reducing downtime.

Investing in quality and technologically advanced brushless motors can yield substantial benefits. For optimal performance, always ensure that the motor is correctly matched to the requirements of your machinery. Regularly updating firmware and software associated with these motors can also enhance their efficiency and extend longevity, making them a reliable option for any industrial application.

The future of brushless motor development is set to revolutionize industrial applications, driven by advancements in technology and the increasing demand for energy-efficient solutions. As industries prioritize sustainability, brushless motors are becoming more appealing due to their lower energy consumption and reduced maintenance requirements. Innovations in materials, such as the use of advanced composites and rare earth magnets, significantly enhance performance and durability, making these motors an ideal choice for a wide range of applications.

Furthermore, the integration of smart technologies into brushless motors will lead to improved monitoring and control capabilities. IoT (Internet of Things) connectivity allows for real-time data collection and analysis, enabling predictive maintenance and optimized operational efficiency. As industries embrace automation and digitalization, the development of brushless motors that are not only powerful but also intelligent is crucial. This trend indicates a shift towards more adaptive and responsive industrial solutions, aligning motor performance with the evolving needs of modern manufacturing processes.