In the world of automation, the choice of motor plays a pivotal role in determining the efficiency and reliability of a system. Among various options available, the BLDC Servo Motor stands out as a top contender, owing to its unique advantages in precision and performance. According to automation expert Dr. Emily Carter, "The BLDC Servo Motor not only enhances operational efficiency but also contributes significantly to energy savings in automation applications." As industries evolve and demand for higher performance grows, understanding the benefits of integrating a BLDC Servo Motor into automation projects becomes essential.

With advancements in technology continually reshaping manufacturing processes, the focus has shifted toward solutions that offer improved accuracy and speed. The BLDC Servo Motor, with its direct drive capability and minimal maintenance requirements, presents a compelling case for engineers and project managers alike. By leveraging its features, businesses can not only optimize their workflows but also reduce downtime, ensuring that production lines remain competitive in an increasingly demanding market. As we explore the top reasons for choosing a BLDC Servo Motor in your upcoming projects, it's essential to recognize how this revolutionary technology can transform automation strategies and drive success.

When considering automation projects, the benefits of using Brushless DC (BLDC) servo motors become increasingly evident. Known for their high efficiency and superior performance metrics, BLDC motors are gaining traction in various applications. The global market for brushless DC motors is projected to grow at a compound annual growth rate (CAGR) of 8.1%, with estimates suggesting a total market size of USD 20.68 billion by 2030. This growth underscores the alignment of BLDC motors with industry demands for higher efficiency and lower operational costs.

BLDC servo motors are particularly appealing due to their ability to provide precise motion control and feedback, crucial in automation settings. Furthermore, the overall electric motor market is expected to reach USD 285.9 billion by 2035, with a CAGR of 6.6% between 2025 and 2035, signifying a robust demand for energy-efficient solutions. As industries seek to enhance productivity and reduce energy consumption, the advantages of BLDC technology will only continue to propel its adoption across multiple sectors.

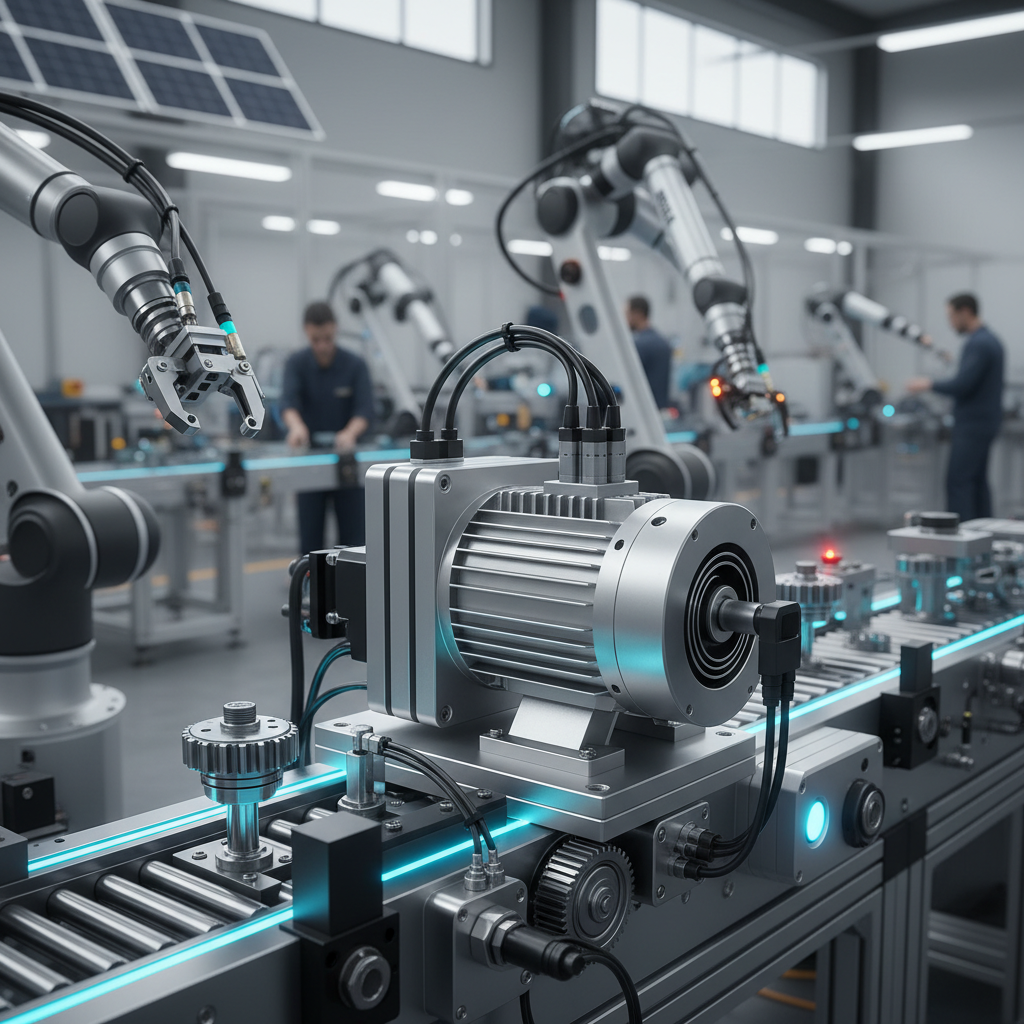

The adoption of BLDC (Brushless DC) servo motors in automation projects is driven by several key industry trends that reflect the need for efficiency and precision in modern manufacturing. One significant trend is the increasing demand for energy-efficient solutions. BLDC motors are known for their superior efficiency compared to traditional brushed motors, leading to reduced energy consumption and operational costs. As industries push toward sustainability, the preference for technologies that lessen their environmental impact is growing, making BLDC motors an appealing choice.

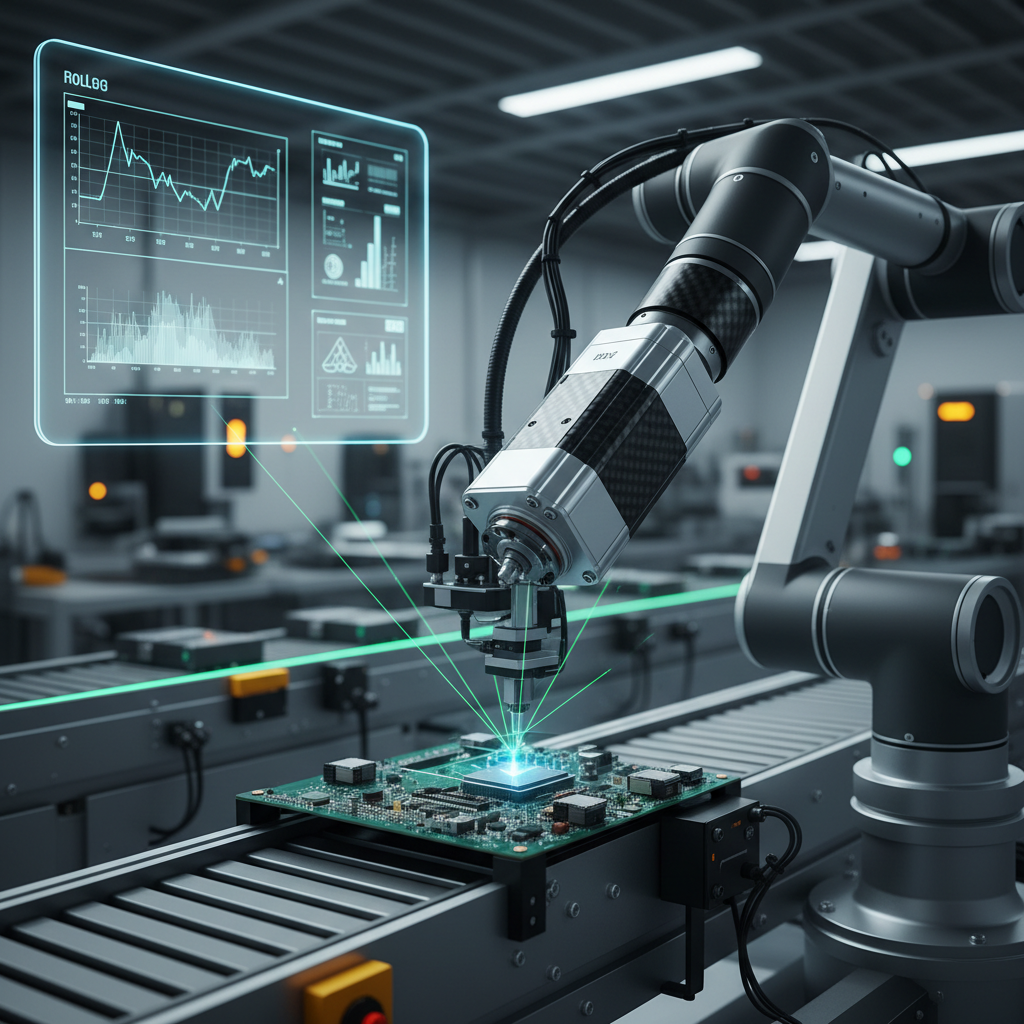

Another trend is the rise of smart automation and Industry 4.0 initiatives. As factories modernize, there is a push for components that can seamlessly integrate with other digital systems and IoT devices. BLDC servo motors offer high levels of precision and responsiveness, making them ideal for applications that require real-time control and adaptability. The ability to easily interface with advanced control systems allows for improved data collection and analytics, facilitating smarter decision-making in manufacturing processes. Consequently, the trend towards intelligent manufacturing systems is steering many companies towards the adoption of BLDC technology.

As automation projects evolve, the choice of motor technology plays a critical role in performance and cost-effectiveness. Brushless DC (BLDC) servo motors are increasingly favored over traditional motor technologies due to their efficiency, reliability, and lower maintenance needs. A comparative cost analysis highlights that while the initial investment in BLDC motors may be higher, the long-term savings from reduced energy consumption and minimal upkeep often outweigh the upfront costs. This cost-efficiency is further amplified by the global market's projected growth, reflecting a increasing trend towards adopting advanced motor technologies.

Moreover, the advantages of BLDC motors extend beyond cost savings to enhanced performance in various applications, including electric vehicles and off-grid water pumping systems. Recent studies have shown that applying advanced control strategies, such as fuzzy logic for speed control in electric vehicles, can optimize the performance of BLDC motors, offering superior efficiency over traditional motor types. With a projected market growth rate of 8.1% CAGR and an increasing demand for electric propulsion systems, the ongoing evolution in motor technology underscores the strategic value of employing BLDC servo motors in future automation endeavors.

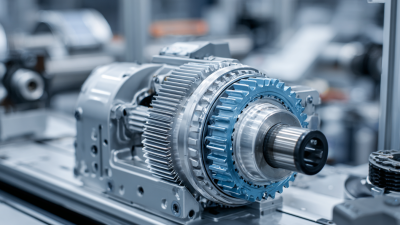

Brushless DC (BLDC) servo motors have gained significant traction in modern automation projects due to their exceptional precision and longevity. According to a report by Research and Markets, the global BLDC motor market size is expected to reach $37.99 billion by 2026, growing at a CAGR of 12.3%. This growth is attributed primarily to the motors’ high torque-to-weight ratio and efficiency, which plays a crucial role in applications that require precise movements and rapid response times.

The technical specifications of BLDC servo motors highlight their suitability for automation. These motors typically feature an advanced control system that allows for precise positioning and smooth operation across a wide range of speeds. The ability to maintain high efficiency even at lower speeds—a critical requirement for many automation tasks—sets BLDC servo motors apart from their brushed counterparts. Additionally, their lifespan can exceed 30,000 hours of operation, significantly reducing maintenance costs and downtime in automated systems. A study by the International Electrotechnical Commission (IEC) states that the reduction in energy consumption alone can enhance operational efficiency by up to 30%, making BLDC motors an attractive choice for energy-conscious businesses.

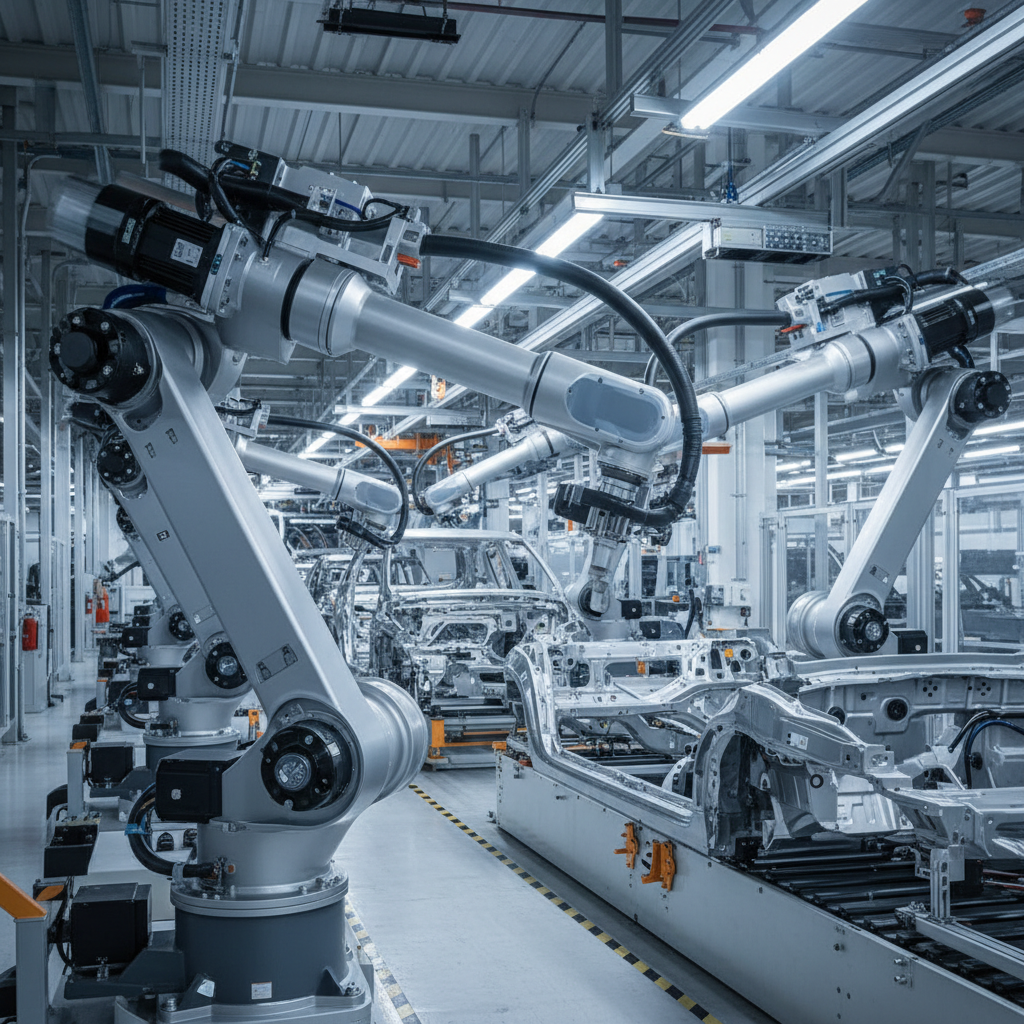

In recent years, the adoption of Brushless DC (BLDC) servo motors has surged across various automation projects, demonstrating significant benefits in real-world applications. One notable case study is in the automotive industry, where a leading manufacturer implemented BLDC servo motors for robotic assembly lines. By integrating these motors, the facility dramatically increased precision and reduced cycle times by 30%. The motors’ high torque-to-weight ratio allowed for faster movements without compromising accuracy, proving essential in maintaining competitive production rates.

Another compelling example can be seen in the packaging sector, where a company revamped its sorting and packaging systems with BLDC servo technology. The switch to these motors enabled the automation of multiple processes, including high-speed sorting and labeling, which improved throughput by 50%. The energy efficiency of BLDC motors also contributed to substantial cost savings, enhancing the overall sustainability of the operation. These cases illustrate not only the efficiency and reliability of BLDC servo motors but also their transformative impact on automation processes in diverse industries.