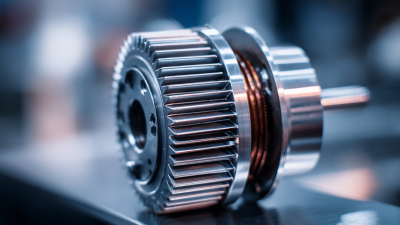

In industrial applications, the choice of motors is critical for efficiency and performance. The Brushless Servo Motor stands out due to its numerous advantages. According to a report by Transparency Market Research, the global brushless servo motor market is expected to reach $10 billion by 2026, reflecting a significant growth trend. This trend indicates a shift towards more advanced motor technologies in various sectors, including robotics and automation.

Industry experts emphasize the benefits of Brushless Servo Motors. Dr. Alex Chen, a prominent figure in motion control technology, once stated, “Brushless Servo Motors provide unmatched precision and dependability.” This statement underscores their significance in applications requiring high accuracy. These motors boast higher efficiency rates and longer lifespans compared to traditional motors. Their design reduces wear and tear, leading to lower maintenance costs.

Businesses must consider the implications of motor selection. While Brushless Servo Motors provide numerous benefits, they can also come with higher initial costs. Understanding the long-term advantages is crucial. As industries continue to evolve, incorporating these advanced motors could yield better results. Companies keen on innovation should reflect on this technology and its significance in maintaining competitiveness.

Brushless servo motors are becoming increasingly popular in modern applications. Their efficiency sets them apart from traditional motors. These motors operate with minimal friction and lower heat generation. They need less maintenance, as there are no brushes to wear out. This reliability can lead to reduced downtime in operations, which is crucial for production.

Another significant benefit is their precise control. Brushless servo motors can achieve high accuracy in position and speed control. This feature is essential in robotics and CNC machinery. A reduction in vibrational noise adds to the comfort of users and operators. Smooth operation is often a key factor in user satisfaction. However, implementing these motors may require more advanced control systems.

Cost can also be a concern. Brushless servo motors might have a higher upfront cost compared to brushed motors. Users must weigh this against long-term savings in maintenance and operational efficiency. Selecting the right technology often involves a balancing act. It may take time to fully grasp the implications of such decisions. Ultimately, understanding these trade-offs is essential for maximizing benefits in real-world applications.

When comparing brushless and brushed servo motors, one can notice distinct differences in performance and efficiency. Brushless motors utilize electronic commutation, which enhances durability and reduces maintenance needs. In contrast, brushed motors rely on physical brushes, resulting in wear over time. This wear can lead to performance degradation, making brushed motors less reliable for long-term applications.

Another key difference is efficiency. Brushless motors convert a higher percentage of electrical energy into mechanical energy. They often run cooler and quieter than their brushed counterparts. This results in increased energy savings, which is crucial for applications demanding precision. However, brushed motors may still have a place in simpler, lower-cost applications despite their limitations.

Additionally, installation considerations play an important role. Brushless motors can require more complicated control systems. This might intimidate some users. However, many prefer the robustness of brushless systems despite the initial learning curve. Both motor types have their use cases, making them suitable for varied applications; it just depends on the specific requirements and constraints present.

| Feature | Brushless Servo Motors | Brushed Servo Motors |

|---|---|---|

| Efficiency | Higher efficiency due to no friction losses | Lower efficiency due to friction in brushes |

| Maintenance | Lower maintenance; no brushes to replace | Higher maintenance; brushes wear out over time |

| Lifespan | Longer lifespan | Shorter lifespan due to brush wear |

| Torque | Provides smoother and higher torque | Typically lower torque capabilities |

| Control | Precise control with advanced feedback | Less precise control compared to brushless |

| Cost | Generally higher upfront cost | Lower upfront cost but higher long-term costs |

Brushless servo motors are increasingly favored in automation and robotics. Their key features truly set them apart. One standout characteristic is their high efficiency. Studies indicate that these motors operate up to 90% efficiency, compared to 70% for brushed motors. This efficiency translates into energy savings and lower operational costs for applications requiring constant use.

Another important feature is their longevity. Brushless designs eliminate friction and wear from brushes, extending the lifespan significantly. Reports show that they can last three times longer than traditional motors. This longevity is essential for minimizing downtime in critical operations. Moreover, they provide smoother motion and superior torque control. This capability enhances precision in applications like CNC machines or robotic arms.

However, not everything is perfect. Brushless servo motors can be more expensive upfront. The initial investment may deter some users. Additionally, they require more complex controllers, adding to the overall cost. Users need to weigh these factors carefully. While efficiency and longevity are significant advantages, the cost implications require serious consideration. Balancing these elements is essential for making informed decisions in automation systems.

This chart compares the key performance metrics of brushless servo motors against traditional motors. Brushless servo motors excel in efficiency, torque density, and have a longer lifespan, making them ideal for various applications.

Brushless servo motors are gaining traction across industries. They provide precision and efficiency in applications like robotics and CNC machines. The automotive sector often relies on them for precise control in electric vehicles and assembly lines. This technology enhances both speed and reliability. It’s not uncommon to find these motors in packaging machines, improving production rates.

Manufacturing plants increasingly choose brushless motors for conveyor systems. They minimize maintenance due to fewer moving parts. However, initial costs can be high, which might deter some businesses. Yet, long-term energy savings often outweigh these drawbacks. Additionally, the complexity of integration can be challenging for teams without sufficient expertise.

In the medical field, they enable precise movements in robotic surgical systems. This leads to better outcomes for patients. Aerospace applications benefit from their compact design and high performance. Despite their advantages, organizations must evaluate whether they truly fit their needs. Adopting new technology always requires careful consideration of potential pitfalls.

The landscape of brushless servo motor technology is evolving rapidly. With advancements in digital controls, these motors are becoming more efficient and accurate. This shift is critical for industries demanding precision. Applications in robotics and automation are on the rise. Users seek systems that reduce energy consumption while improving performance.

Environmental concerns also drive innovation. Brushless servo motors are often more eco-friendly than their brushed counterparts. They generate less waste and heat, promoting sustainable practices. However, there are challenges. Integrating new technologies can be costly. Companies must weigh benefits against initial investments. Prototyping and testing remain essential steps in adopting these advancements.

As more manufacturers transition to smart systems, the need for adaptability increases. The future will likely see more interconnected motors using IoT technologies. This trend raises questions about cybersecurity in industrial applications. Companies must prioritize security alongside efficiency. Balancing innovation and safety is critical in this evolving landscape.