In the ever-evolving world of modern engineering, the choice of motors plays a crucial role in determining the efficiency and performance of any project. Frameless DC Motors have emerged as a leading solution for a variety of applications, ranging from robotics to aerospace, due to their compact design and exceptional torque capabilities. According to Dr. Martin Keller, a renowned expert in the field of electric motors, "Frameless DC Motors offer unparalleled flexibility and performance in tight spaces, making them perfect for innovative engineering solutions."

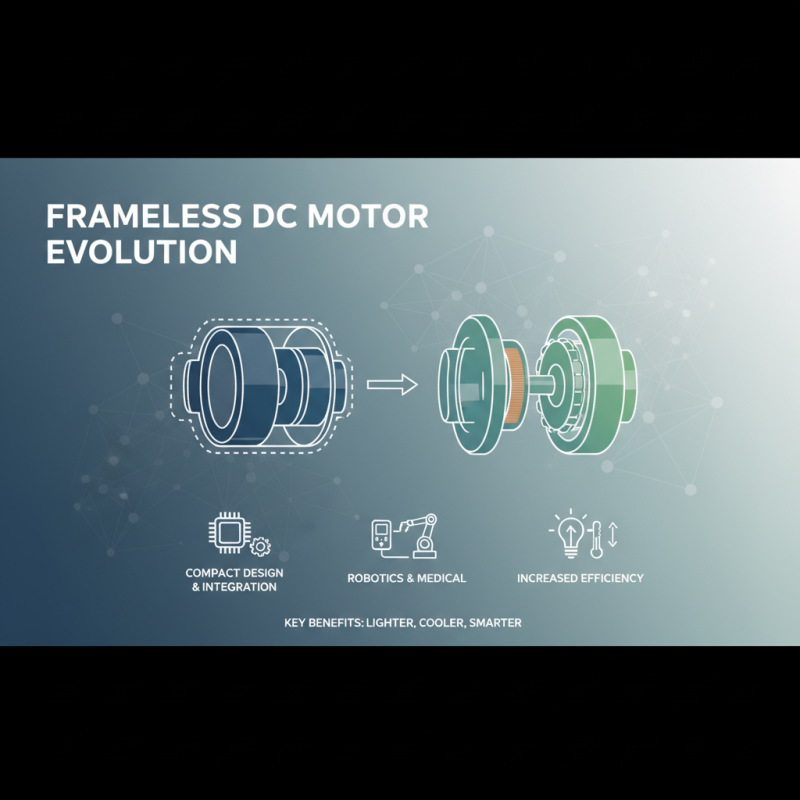

These motors, characterized by their unique construction without a traditional frame, allow for easier integration into customized systems where space and weight are critical factors. The absence of an exterior frame not only reduces the overall weight but also enhances heat dissipation, resulting in improved efficiency. As technology progresses, engineers are increasingly recognizing the advantages offered by Frameless DC Motors, paving the way for pioneering applications that require high power density and precision.

In summary, choosing Frameless DC Motors for your next project can provide significant benefits, including reduced space constraints and increased operational efficiency. By understanding the unique features and advantages of these motors, engineers can leverage their potential to create cutting-edge solutions that meet the demands of today's fast-paced technological landscape.

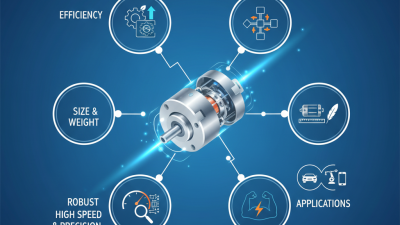

Frameless DC motors are increasingly becoming the go-to choice for engineers and designers in various applications due to their unique features and significant advantages. Unlike traditional motors, frameless DC motors lack an outer casing, allowing for a more compact design and greater flexibility in integration into tight spaces. This arrangement not only reduces the overall weight but also minimizes the inertia of the system, making them ideal for dynamic applications requiring rapid acceleration and deceleration. According to a report by the International Electrotechnical Commission, frameless motors can enhance system efficiency by as much as 30% in certain configurations.

Another significant benefit of frameless DC motors is their superior torque density. With enhanced performance characteristics, these motors often deliver higher torque in a smaller footprint, which is critical for advanced robotics and medical devices. A study conducted by the Robotics Industries Association indicates that integrating frameless motors can lead to a 25% improvement in energy efficiency, allowing equipment to operate longer on less power without compromising performance. Furthermore, the modular design of these motors facilitates easy maintenance and customization, allowing engineers to tailor the motor to specific application requirements, thus reducing development costs and time to market.

Frameless DC motors are increasingly becoming the go-to choice for various industries due to their versatility and compact design. Their applications span across fields such as robotics, medical devices, and aerospace. In robotics, frameless DC motors are favored for their high power-to-weight ratio and ability to fit into tight spaces, making them ideal for robotic arms and drones where size and weight are critical considerations. With their smooth operation and precise control, these motors enhance the performance and efficiency of robotic systems.

In the medical sector, frameless DC motors play a crucial role in the development of surgical instruments and diagnostic equipment. Their precision is vital for applications such as minimally invasive surgeries where the slightest error can have significant consequences. The ability to customize these motors for specific functions further elevates their value in healthcare technologies.

**Tips:** When considering frameless DC motors for your project, focus on the torque and speed requirements specific to your application. Additionally, evaluate the integration capabilities with control systems to ensure optimal performance. Always keep in mind the importance of selecting the right materials to enhance durability and efficiency in high-demand environments.

Frameless DC motors have emerged as a formidable alternative to traditional motors, particularly in applications requiring high precision and compact design. One of the primary advantages of frameless DC motors is their ability to reduce size and weight without sacrificing performance. According to a recent industry report from ResearchAndMarkets, frameless motors boast efficiency ratings upwards of 90%, significantly higher than the typical 70-80% efficiency of traditional brushed motors. This efficiency translates into reduced thermal buildup and improved reliability, making frameless DC motors suitable for advanced robotics, aerospace, and medical devices.

Moreover, frameless DC motors offer greater versatility in mounting configurations. Their design allows for seamless integration into various mechanical assemblies, enabling engineers to create more compact and efficient systems. A study by the Institute of Electrical and Electronics Engineers highlights that the torque-to-weight ratio in frameless DC motors can be up to 30% higher than that of conventional motors, providing enhanced dynamic response in critical applications. This advantage is particularly pivotal in sectors like automation and automotive technologies, where space and performance are paramount. By eliminating the traditional motor housing, frameless designs maximize usable volume while facilitating cooling and maintenance, thus making them a go-to choice for modern engineering challenges.

When selecting frameless DC motors for your next project, several crucial factors should guide your decision. First and foremost, consider the motor's size and weight. Frameless designs are ideal for applications where space is limited and weight is a critical factor, such as in robotics or aerospace. Evaluating the motor dimensions in relation to your design specifications will ensure optimal integration and functionality. Additionally, assess the winding configurations and magnet types, as these influence the torque and efficiency of the motor, impacting overall performance.

Another essential factor is thermal management. Frameless DC motors often operate in environments where heat dissipation is vital to prevent overheating and ensure longevity. It is crucial to analyze the thermal characteristics of the motor, including its ability to handle heat under load conditions. Furthermore, examine the motor's power and control requirements. Understanding the voltage and current characteristics will aid in selecting compatible drivers and controllers, ensuring seamless system integration. By carefully considering these aspects, you can choose the right frameless DC motor that aligns perfectly with your project's technical demands.

Frameless DC motor technology is rapidly evolving, driven by advancements in design and application requirements. In recent years, there has been a notable shift towards more compact and efficient designs, which allow for greater integration into diverse products. The trend of miniaturization in consumer electronics and industrial automation has propelled designers to opt for frameless DC motors, eliminating the need for bulky housings while enhancing performance. This results in not only lighter overall weight but also reduced thermal and mechanical strain, fostering improved energy efficiency in applications ranging from robotics to medical devices.

Additionally, innovations in control algorithms and sensor integration are enhancing the capabilities of frameless DC motors. With the rise of smart technology, more sophisticated feedback mechanisms are being incorporated, allowing for precise and responsive control. This enables applications to achieve higher accuracy and responsiveness, which is essential in dynamic environments. The adoption of advanced materials is also on the rise, leading to increased durability and performance under demanding conditions. As these trends continue to develop, frameless DC motors will play a pivotal role in shaping the future of automation and intelligent systems, ultimately driving progress across various industries.