In today's rapidly advancing technological landscape, selecting the right components is critical for the success of any engineering project. Among these components, the Frameless Brushless DC Motor has gained immense popularity due to its unique characteristics and advantages over traditional motors. According to a recent industry report by Research and Markets, the global brushless DC motor market is expected to experience significant growth, projected to reach USD 25 billion by 2026, reflecting an annual growth rate of more than 7%. This rising demand is largely attributed to the transformative benefits frameless designs offer, including reduced size and weight, which are essential for applications requiring high precision and efficiency. As engineers and developers increasingly prioritize performance and reliability, understanding the nuances of Frameless Brushless DC Motors becomes vital in making informed decisions that align with the specific needs of their projects.

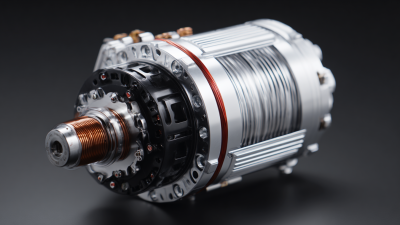

Frameless brushless DC motors (BLDC) have emerged as a preferred choice for numerous applications, ranging from robotics to medical devices. Understanding the basics of these motors is essential for selecting the optimal model for your project. Unlike traditional motors, frameless BLDC motors offer a compact design that integrates seamlessly into various systems, providing high efficiency and superior performance. Reports indicate that the global brushless DC motor market is projected to reach $23.2 billion by 2026, with a CAGR of 10.45%, driven by their increasing adoption in automation and electric vehicles.

Key specifications such as torque density, power-to-weight ratio, and thermal characteristics should be evaluated. For instance, a study from Research and Markets highlighted that frameless BLDC motors achieve torque densities of up to 5 Nm/kg, making them ideal for applications where space and weight are critical. Additionally, understanding the thermal performance is crucial, as these motors can operate at higher temperatures without compromising efficiency. The ability to customize the motor design, including rotor and stator configurations, makes frameless BLDC motors highly adaptable, catering to diverse project requirements. Thus, leveraging these insights can significantly enhance the selection process for your project.

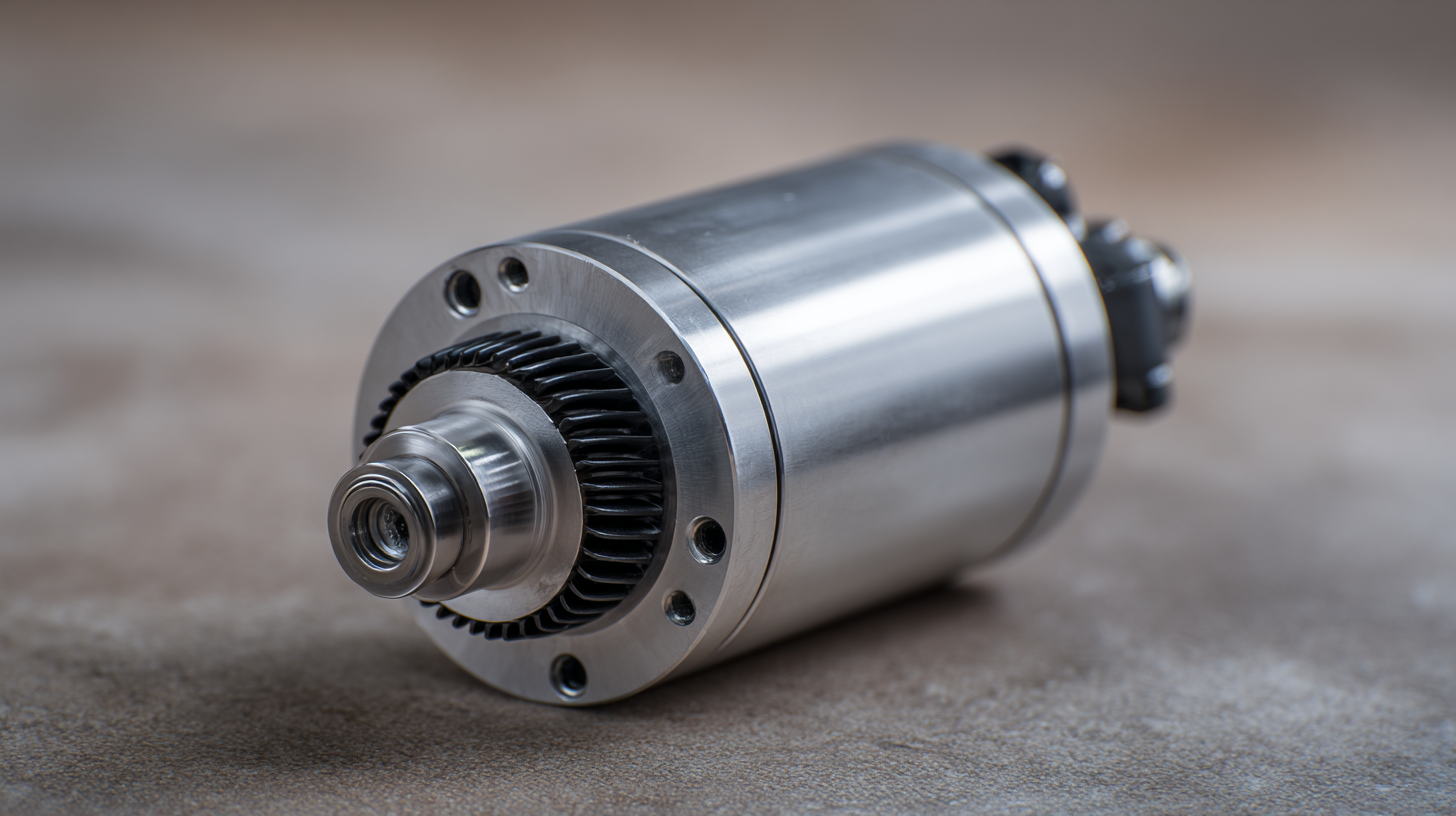

When selecting a frameless brushless DC motor for your application, key specifications play a critical role in ensuring optimal performance and efficiency. One of the most important factors to consider is the motor's torque-to-weight ratio, which directly influences the motor’s responsiveness and capacity to handle loads. Recent industry reports indicate that the best high-performance frameless motors can achieve a torque-to-weight ratio of up to 4.0 Nm/kg, making them suitable for demanding applications like robotics and aerospace.

Another significant specification is the motor's cooling method, as it affects the longevity and constancy of performance. Active cooling systems, such as liquid cooling, can enhance the thermal management of high-power motors, allowing them to maintain efficiency under heavy workloads. According to a 2022 study by the International Journal of Electronics, motors employing advanced cooling techniques can sustain 95% efficiency even at peak currents, compared to 85% for those without such systems. Lastly, it’s essential to assess the compatibility of the motor with your control system, as seamless integration can drastically reduce programming complexity and improve system responsiveness.

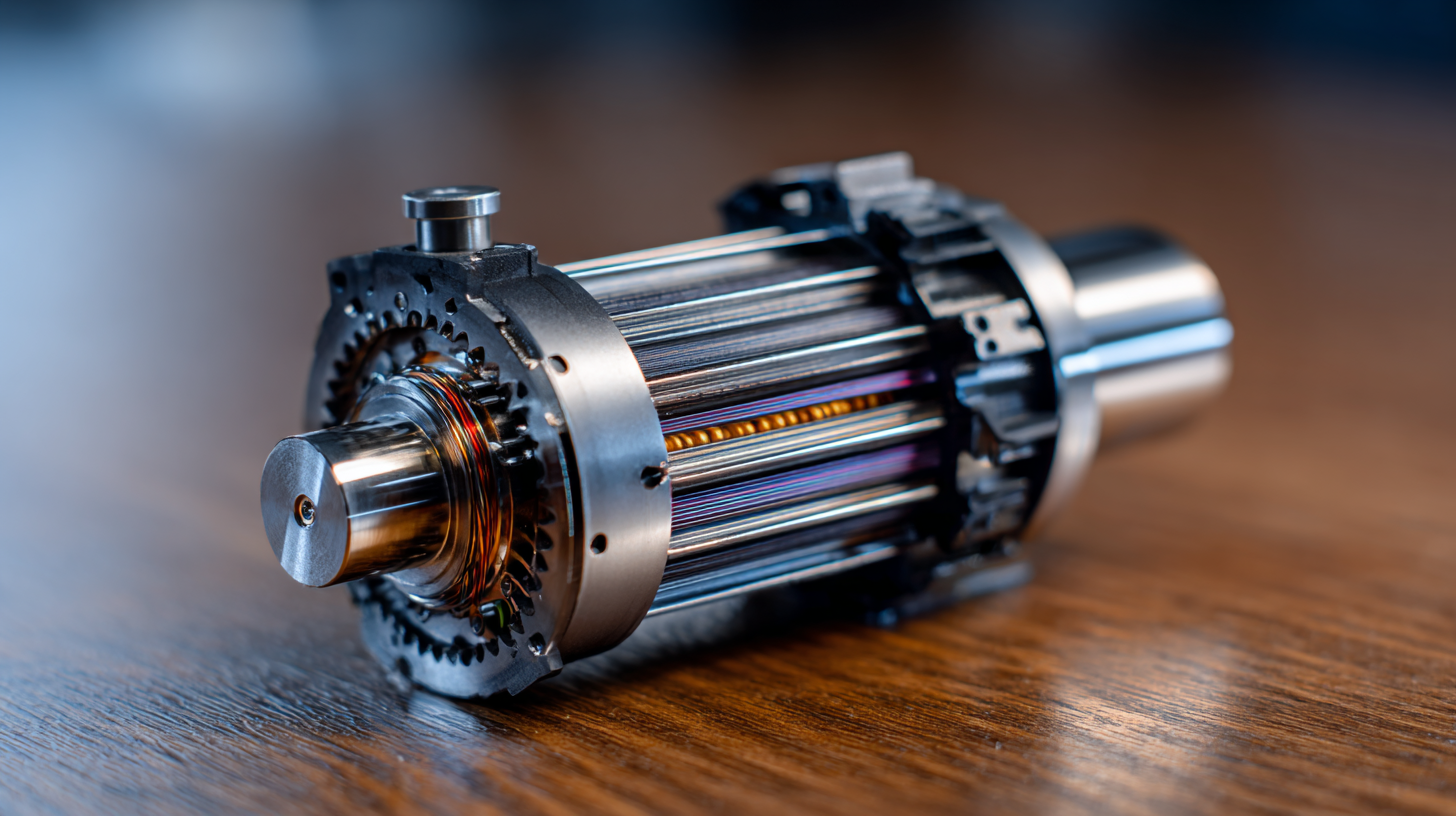

When selecting a frameless brushless DC motor, efficiency ratings play a crucial role in determining the best model for your project.

Recent industry reports indicate that the efficiency of these motors can vary substantially, with some high-performance models achieving efficiencies of up to 95%. In comparison, lower-end alternatives may only reach 75% efficiency, which can significantly impact the overall energy consumption and operational costs of your application.

Moreover, factors such as load conditions, motor design, and cooling systems further influence these efficiency ratings. For instance, a comparative analysis from the Electric Motor Systems Market report reveals that motors equipped with advanced cooling technology can enhance electrical efficiency by as much as 10%. This emphasizes the need for careful consideration of the operating environment and application requirements when selecting a motor. Taking the time to analyze these efficiencies not only ensures optimal performance but also maximizes the longevity and reliability of your motor system.

When selecting a frameless brushless DC motor, understanding the balance between cost and performance is crucial. According to the "2023 Global Motor Market Report," the price of brushless DC motors has seen a significant decrease, averaging around 12% from previous years, making them more accessible for various projects. However, it's essential to consider not just the upfront costs but also the long-term efficiency and reliability of the motor, which can impact the total cost of ownership.

Performance metrics such as torque, speed, and thermal efficiency are critical when evaluating motors. Data from the "2022 Performance Benchmarking Study" reveals that high-efficiency motors can save up to 30% in energy costs over their lifetime compared to lower-efficiency options. This means that while initial investment may differ, choosing a more efficient motor can lead to substantial savings in operational costs. By carefully analyzing these factors, engineers can make informed decisions that not only suit their budget but also optimize performance for their specific applications.

The landscape for frameless brushless DC motors is evolving rapidly, driven by technological innovations and rising demand across various industries. According to a recent report by MarketsandMarkets, the brushless DC motor market is projected to grow from $18.1 billion in 2022 to $30.5 billion by 2027, at a compound annual growth rate (CAGR) of 10.8%. This growth is primarily fueled by applications in robotics, automation, and electric vehicles, where the need for lightweight and efficient motor solutions is critical.

One notable trend is the integration of IoT capabilities in motor design. As manufacturers focus on enhancing motor performance, they are increasingly incorporating smart technology that allows for real-time monitoring and predictive maintenance, thus improving operational efficiency. Additionally, advancements in materials science have led to the development of more robust and reliable components, making frameless motors suitable for harsher environments. As highlighted by a study from ResearchAndMarkets, the demand for direct drive systems, which depend heavily on brushless motors, is surging, particularly in precision applications like CNC machinery and medical devices, where accuracy and reliability are paramount.