Choosing the right BLDC electric motor is crucial for your project's success. These motors offer efficiency and reliability. However, picking the best one can be challenging. Each project has unique demands.

When selecting a BLDC electric motor, consider your requirements carefully. Think about the power, speed, and size you need. Not all motors are the same. Some may not match your project's specifications. It's important to understand the parameters. A wrong choice can lead to performance issues.

Look closely at manufacturer details. They often have specifications that reveal suitability. Compare different options. Sometimes, the most advertised product may not be the best fit. Explore user reviews and feedback. They can provide real-world insights. Reflect on what others experienced. This process requires attention to detail and sometimes, a bit of trial and error.

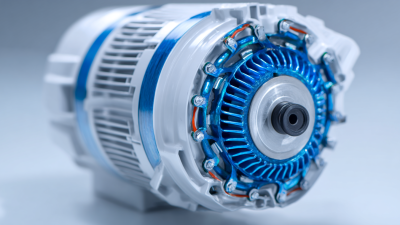

When selecting a BLDC electric motor for your project, several factors come into play. The application demands high efficiency. According to industry reports, the efficiency of BLDC motors can reach up to 90%. Understanding the specific needs of your design will guide you in choosing the right motor. Are you prioritizing speed, torque, or compactness? Each element can greatly influence the performance.

Next, look at the motor specifications. Voltage ratings can range from 5V to 48V. Selecting the right voltage is crucial for optimal performance. Additionally, consider the motor's size, weight, and mounting options. These factors can affect the overall design. A motor that's too bulky may not fit your project, leading to adjustments that could compromise your timelines.

Another point to ponder is thermal management. BLDC motors generate heat, especially at high loads. Neglecting proper cooling solutions may lead to reduced motor life or performance issues. The ideal motor should offer a balance between power requirements and thermal tolerance. Research indicates that about 30% of motors fail due to overheating. This knowledge highlights the importance of proper selection and planning.

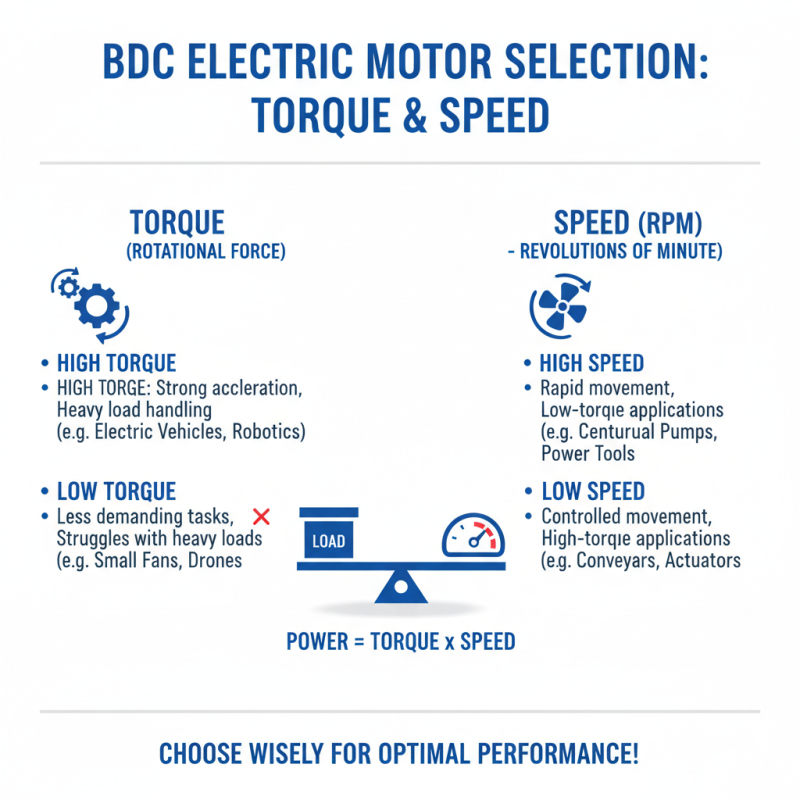

When selecting a BLDC electric motor, understanding torque and speed ratings becomes crucial. Torque is the rotational force produced by the motor. It significantly influences the motor's performance in various applications. For example, a motor with higher torque is ideal for tasks that require strong acceleration and load handling. Conversely, a low-torque motor may struggle in high-demand situations, leading to inefficiencies.

Speed ratings refer to how fast the motor can rotate. These ratings are measured in RPM (revolutions per minute). A high-speed rating benefits applications that need rapid movements. However, some projects may not require high speeds at all. Balancing torque and speed is fundamental. A motor that excels in one area may falter in another.

Choosing the right combination can be tricky. Too much focus on either torque or speed could lead to project failures. Reflect on the specific needs of your project before making decisions. Testing multiple motors can also provide practical insights into their performance. Each application may present unique challenges that only real-world trials can uncover.

When selecting a BLDC electric motor, power consumption is key. Not all motors are created equal. Comparing the efficiency of different models is crucial. A more efficient motor will consume less energy, leading to cost savings over time.

You should consider the torque rating and RPM. High torque at low RPM may require more power, while high RPM might consume less in some cases. Understanding these dynamics helps in making an informed choice. Testing motors under actual load conditions offers real insights. You might discover unexpected results that can influence your decision.

Not every motor suits every application. Some might perform well in lab settings but fail under practical use. Evaluating real-world performance is essential. Be cautious about assumptions. Look into different operating conditions. Consider thermal management as it impacts efficiency. Getting these details right can be the difference between success and failure in your project.

| Motor Type | Voltage (V) | Rated Power (W) | Efficiency (%) | Current Draw (A) | Use Case |

|---|---|---|---|---|---|

| BLDC Motor A | 24 | 250 | 90 | 10.4 | Robotics |

| BLDC Motor B | 36 | 500 | 85 | 14.4 | Drone |

| BLDC Motor C | 48 | 750 | 92 | 15.6 | Electric Bicycle |

| BLDC Motor D | 12 | 100 | 80 | 8.3 | Small Appliances |

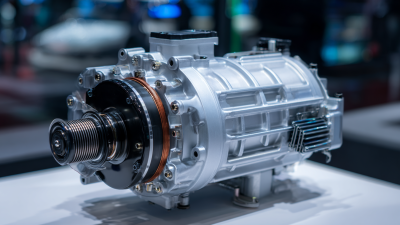

When assessing size and weight constraints for a specific application, it is crucial to think beyond mere dimensions. The overall efficiency of a BLDC (Brushless DC) electric motor greatly depends on its size-to-weight ratio. For instance, reports indicate that reducing motor weight by just 10% can enhance energy efficiency by 5% in many cases. This can lead to a noticeable improvement in performance, especially in portable devices.

Consider the application of a drone. The motor's weight directly impacts flight time and maneuverability. A heavier motor may provide more torque but could decrease overall efficiency. It's essential to balance the weight with the required power output. According to industry studies, achieving a compact design while maintaining sufficient power density is key. Designers often face the challenge of optimizing motor size without compromising functionality.

Another critical aspect is thermal management. Smaller motors can overheat in tight spaces, which might shorten their lifespan. A motor that seems perfect in size could fail under performance due to inadequate heat dissipation. Designers must assess the environment where the motor will operate. Are there enough cooling options? This reflection is vital for successful projects. Understanding these dynamics leads to better decision-making in motor selection.

When selecting a BLDC electric motor, cost-effectiveness is crucial. It's essential to identify your project's specific needs. Consider power requirements, speed, and torque. A higher efficiency motor may cost more upfront but could save money in the long run. Check the initial purchase price and operational costs.

Budget considerations play a significant role in motor selection. Always balance performance and expense. Sometimes, cheaper motors underperform, leading to higher maintenance costs. Assess your budget carefully. For prototyping, it might make sense to test lower-cost models. This can help validate your design. Watch out for hidden expenses such as control systems and installation.

Flexibility in your budget can lead to better choices. If the project evolves, you may need a more robust motor. This could increase your overall costs. Remain open to revisiting your budget as your needs change. It's vital to reflect on the potential trade-offs. Not every decision will be perfect, but careful consideration will guide you.