In today's rapidly evolving technology landscape, selecting the right motor is crucial. Frameless BLDC motors have emerged as a preferred choice for many applications due to their unique design and versatility. According to a recent market report, the global brushless DC motor market is projected to grow at a compound annual growth rate (CAGR) of 10.2% from 2021 to 2028. This growth highlights the increasing demand for efficient and compact motor solutions.

Frameless BLDC motors offer several advantages, such as improved torque density and reduced installation space. Their design eliminates the traditional housing, which can lead to lighter and more efficient systems. Many industries, including robotics, aerospace, and medical devices, are actively adopting this technology. However, it's essential to consider potential drawbacks, such as the need for custom integration and higher upfront costs.

The choice of a frameless BLDC motor must align with specific application requirements. Factors like load characteristics and environmental conditions can affect performance. As demand for innovative motor solutions continues to rise, it's critical for engineers to weigh the benefits and challenges of these advanced motors carefully.

Frameless BLDC motors are gaining attention for their unique design and functionality. Unlike traditional motors, these motors do not have an outer casing. This allows them to be compact and lightweight, making them suitable for various applications. Their design offers flexibility in installation. Engineers can integrate them easily into existing systems.

These motors function using magnetic fields and electronic commutation. They can deliver precise control and high efficiency. The absence of bearings in some models reduces friction and wear. However, users should consider the trade-offs. The installation might require more precise engineering. This can lead to higher initial costs and complexity.

Many factors contribute to the choice of frameless BLDC motors. Sometimes, the benefits are clear, but not always. For example, their performance in extreme conditions may vary. It raises questions about reliability and maintenance. Understanding their operational limits is crucial. Without proper planning, issues may arise during usage. The unique attributes of frameless BLDC motors offer potential, but they also demand careful consideration.

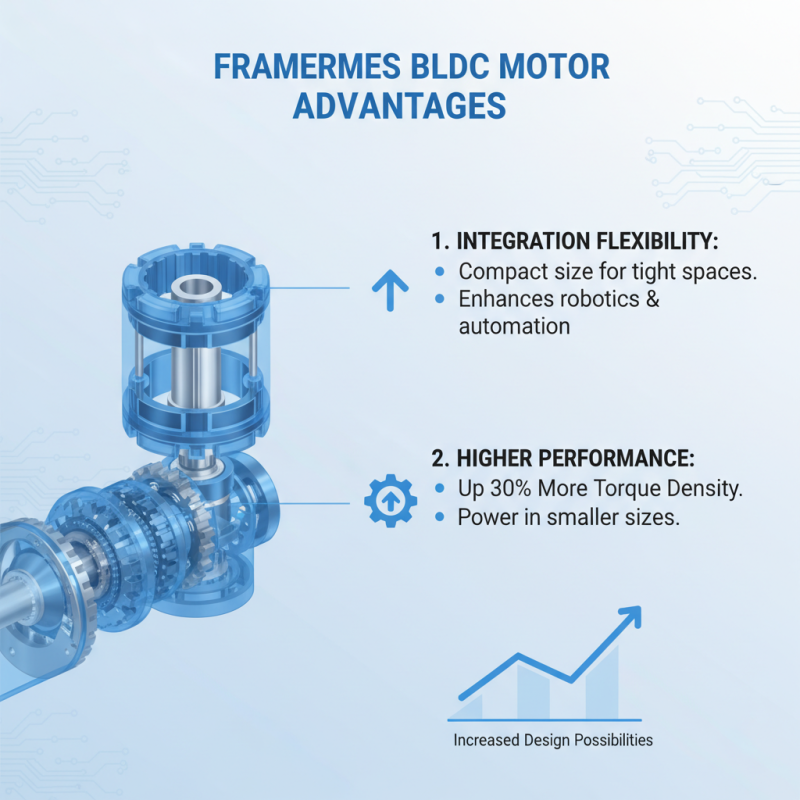

Frameless BLDC motors are gaining popularity across various industries. They offer unique advantages that cater to specific needs. One major benefit is their compact design. This allows for flexible integration into tight spaces. In robotics, for instance, this compactness leads to lighter designs, improving performance and efficiency.

Another key advantage of frameless BLDC motors is their high torque-to-weight ratio. This feature is crucial in applications requiring precision and speed. For medical devices, such as surgical equipment, this translates to smoother operation. Moreover, these motors provide reliable performance at lower noise levels. Such characteristics are vital in environments where noise control is important.

While frameless BLDC motors have many benefits, they also present challenges. The lack of a traditional frame means they require careful handling. This can complicate installation. Additionally, customization may be more demanding compared to typical motors. Users need to consider these factors when choosing the right solution for their application.

Frameless BLDC motors offer several advantages over traditional motor designs. One key differentiator is their integration flexibility. Without a bulky frame, they can fit into tight spaces. This versatility enhances design possibilities in robotics and automated systems. Industry reports indicate that frameless motors can provide up to 30% more torque density. This means they can deliver higher performance in smaller sizes.

Traditional motors often face challenges with efficiency. They typically have more mechanical losses due to their structure. In contrast, frameless design minimizes energy loss. According to a study by the International Electrotechnical Commission, frameless BLDC motors can achieve efficiency levels above 90%. This substantial improvement can lead to significant energy savings in long-term applications.

However, frameless motors can come with their own complexities. For example, assembly requires more precision. A slight misalignment can lead to performance issues. Additionally, the absence of a frame may necessitate more careful management of thermal dynamics. Balancing these factors is essential for optimizing their use in various applications.

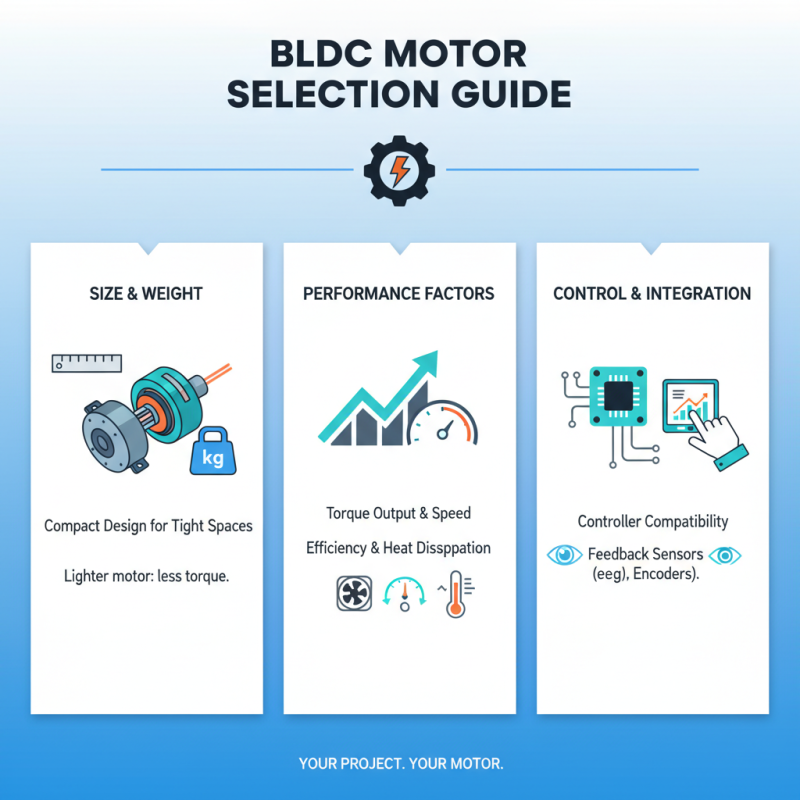

When selecting frameless BLDC motors for your projects, several factors warrant your attention. First, consider the size and weight of the motor. A compact design enhances integration into tight spaces. You might be surprised how small changes can affect performance. Be mindful that a lighter motor can sometimes compromise torque.

Next, evaluate the power requirements of your application. Frameless motors often provide high efficiency. However, it’s crucial to match voltage and current specifications accurately. An incorrect match can lead to unsatisfactory performance. You may want to gather detailed specifications and test prototypes. This helps you avoid unexpected issues later in the project.

Also, think about the coil configuration. Different setups yield various performance characteristics. Some configurations might lead to higher costs, while others may underperform. Ensuring a balance between cost-effectiveness and quality is key. Rushing this phase can lead to regrets down the line. Reflect on your choices carefully as they directly impact the success of your application.

Frameless BLDC motors are gaining traction due to their compact design and high efficiency. Industry reports indicate a forecasted growth of around 10% in the BLDC motor market by 2027. This trend reflects a shift towards automation and advanced robotics. Manufacturers are constantly innovating, leading to improved performance in power-to-weight ratios.

Recent innovations include enhanced cooling techniques and smart control algorithms. These advancements allow for higher speeds and better torque management. Trends show that the integration of IoT is also rising. This allows for better monitoring and predictive maintenance, crucial for industries reliant on operational uptime.

Tips: Consider using frameless motors for space-constrained applications. They fit easily into tight designs. Keep an eye on evolving technologies, as they may offer potential efficiency gains. Always evaluate the trade-offs between performance and complexity, as not all innovations may align with your needs.