Choosing the right motor for specific applications can significantly influence performance and efficiency, especially when it comes to high torque requirements. As John Smith, a leading expert in the high torque BLDC (Brushless Direct Current) motor industry, once stated, "The right high torque BLDC motor can transform an application, providing the power and precision needed to meet today's demanding standards." With their unique design and operational benefits, high torque BLDC motors are increasingly becoming the go-to solution for various applications, ranging from industrial machinery to electric vehicles.

Understanding the parameters that define high torque BLDC motors is essential for engineers and designers seeking to optimize their projects. Torque, efficiency, and size all play a pivotal role in determining which motor will best suit specific needs. This introductory guide will explore the key considerations involved in selecting high torque BLDC motors, highlighting the importance of aligning motor characteristics with application demands. By delving into factors such as load requirements and speed variations, users can make informed decisions that lead to enhanced performance and reliability.

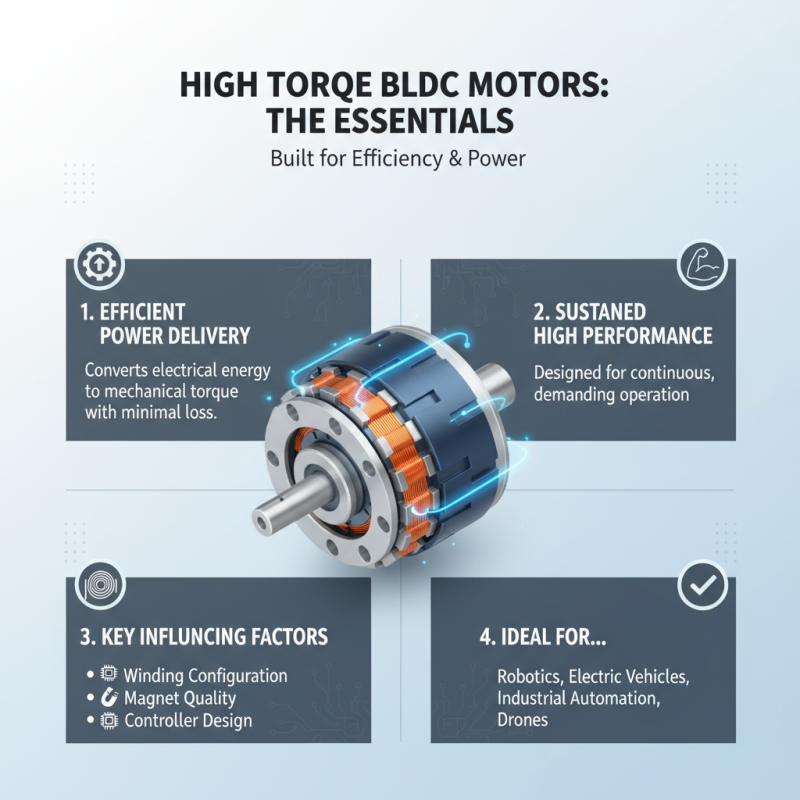

When developing a brushless motor controller from scratch, understanding the basics of high torque BLDC (Brushless DC) motors is crucial. These motors are designed to provide efficient and powerful torque, making them ideal for various applications. High torque BLDC motors are characterized by their ability to sustain high levels of performance over extended periods, which is essential in scenarios requiring consistent operation. Factors such as the motor’s winding configuration, magnet quality, and the controller's design significantly influence overall performance.

To achieve optimal performance in your motor controller, it is essential to consider the specific requirements of your application. Selecting the right motor involves evaluating factors such as torque speed curves, load characteristics, and heat dissipation. Furthermore, integrating sensors for feedback control can enhance performance, providing a smoother operation. As you build your controller, pay attention to the design of your power electronics and control algorithms, which will ultimately determine how effectively the motor responds to commands and maintains desired torque levels during operation.

When selecting high torque BLDC motors for applications that demand superior performance, it is essential to consider key specifications that can influence efficiency and functionality. Key factors include torque rating, RPM, size, and power consumption. For instance, a higher torque rating can significantly improve the performance of electric vehicles and robotics, ensuring they can handle greater loads with ease.

**Tips:** When evaluating a motor, pay close attention to its torque-to-weight ratio, as this can impact both transportability and overall application performance. Additionally, consider the environmental conditions where the motor will operate; understanding its thermal limits and protection ratings can prevent premature failures.

Market trends indicate a growing demand for high torque synchronous motors, particularly in Europe, where revenue is projected to make significant gains within the next few years. As industries increasingly depend on precision and power, the choice of motor not only affects current projects but can also shape future innovations in high torque applications.

**Tips:** Always compare several models and manufacturers to find the most suitable torque characteristics and ensure they fit within your project’s specifications. Analyzing market trends can provide insights into emerging technologies that may elevate your application’s performance.

When selecting high torque Brushless Direct Current (BLDC) motors, assessing both efficiency and performance is crucial to ensuring optimal application outcomes. According to a report by the International Electrotechnical Commission (IEC), BLDC motors can achieve efficiency levels up to 90%, significantly higher than traditional brushed motors which typically range from 60% to 80%. This efficiency translates into reduced energy consumption and lower operating costs, making BLDC motors an ideal choice for applications ranging from robotics to electric vehicles.

Another key performance metric is torque density, which refers to the amount of torque produced per motor volume. Industry data indicates that high torque BLDC motors can reach torque densities exceeding 2 Nm/L, greatly enhancing their suitability for compact and high-performance applications. Furthermore, advancements in computing and control algorithms have led to the development of sensors and sensorless control techniques that optimize motor response and enhance performance under varying loads. The ability to maintain consistent performance while maximizing torque output illustrates the integral role of efficient design and technology in selecting the most suitable BLDC motor for demanding applications.

When selecting the right drive and controller for high torque BLDC motors, it is essential to understand the specific requirements of your application. The drive system must match the motor's operational needs, including the voltage, current, and control methods. Recent advancements in embedded microcontroller-driven gate drivers support more efficient communication and precise control, enabling higher performance and adaptability in various applications such as robotics and electric vehicles.

Moreover, the trending integration of microcontrollers in motor drive solutions allows for better performance optimization and energy management. These developments highlight the importance of choosing both a reliable motor and a compatible drive system, which can significantly impact the efficiency and reliability of the overall system. As the market demands increasingly sophisticated solutions, leveraging technologies that facilitate seamless coordination between motors and controllers is crucial for achieving optimal performance in any demanding application.

High torque BLDC (Brushless Direct Current) motors are widely utilized across various industries due to their efficiency and reliability in applications requiring significant power and precise control. These motors excel in environments such as robotic arms in manufacturing, electric vehicles, and conveyor systems where performance and responsiveness are critical. The need for high torque translates into better acceleration and stability, making BLDC motors a go-to solution for demanding tasks.

When selecting a high torque BLDC motor for your application, consider the specific requirements such as load capacity, speed control, and the operating environment. For instance, in robotics, a motor that provides high torque at low speeds is essential for delicate operations, while in electric vehicles, high torque at higher speeds is necessary for acceleration.

Tips: Always assess the required torque curve of your application to match it with the motor specifications. Additionally, look for motors with a higher continuous torque rating than the peak torque needed during operation to ensure durability and reliability over time. Finally, consider the cooling measures required, as high torque applications can generate significant heat, impacting performance and lifespan if not managed properly.