Choosing the right Industrial Brushless Motor can significantly impact your application's performance and efficiency. These motors offer numerous advantages, including higher reliability and better energy performance. However, selecting the ideal motor is not always straightforward.

Consider the specific requirements of your application. Think about factors like speed, torque, and size. Each application has different needs, and one size does not fit all. It's crucial to assess load demands and environmental conditions. For instance, motors used in harsh environments require extra protection.

Many users overlook details. They may focus solely on power ratings or price. Yet, the right motor can reduce maintenance costs. It should also improve overall productivity. Remember, a well-informed choice can save you time and money down the line. Be wary of common mistakes to avoid.

Understanding the basics of industrial brushless motors is essential for making the right choices. These motors use electronic controllers instead of brushes. This design leads to improved efficiency and longevity. They generate less heat and eliminate mechanical wear. Regular maintenance is minimized, which saves time and costs.

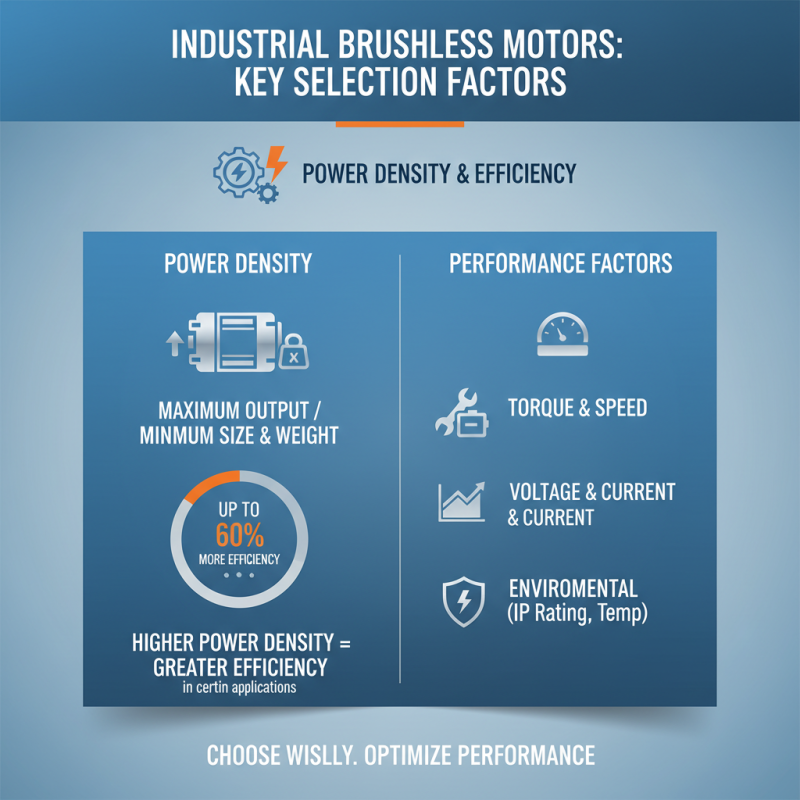

When selecting a brushless motor, consider the application requirements. Factors such as torque, speed, and size are crucial. For instance, in robotics, high torque is needed for movement. In HVAC systems, precise speed control is vital for energy efficiency. Evaluate the power supply as well. Some motors operate on AC, while others use DC. The right choice will depend on your specific needs.

Sometimes, even with precise calculations, errors occur. Perhaps the torque is less than expected. Or maybe the speed fluctuates. This can lead to inefficiencies or even project delays. Reviewing your application and expected outcomes can help identify these issues. Always keep in mind that the best choice may not always be the simplest.

Choosing the right industrial brushless motor starts with understanding your specific application requirements. Identify the load type you will drive. Is it constant or variable? Knowing if the load is heavy or light affects torque and power requirements. The intended speed range is crucial too. A motor that can't meet speed demands may lead to inefficiencies.

Next, consider environmental factors. Will the motor operate indoors or outdoors? Temperature and humidity can significantly impact performance. Enclosure type is another aspect. A sealed motor might be necessary for dusty or wet conditions. Watch for the motor's ingress protection (IP) rating.

Lastly, reflect on power supply options. Brushless motors typically require specific voltages and phases. Assessing available power sources helps avoid compatibility issues. Overlooking these details can result in costly errors. Remember, a mismatch might not be evident until installation. Taking the time to thoroughly analyze your needs can lead to smarter decisions.

Choosing the right industrial brushless motor requires careful evaluation of its performance factors. Power density is crucial. Motors need to deliver maximum output while minimizing size and weight. According to industry reports, motors with higher power density can achieve up to 60% more efficiency in certain applications.

Speed and torque characteristics also matter. A motor's optimal speed range should match application requirements. For instance, some tasks demand high torque at low rpm, while others require fast speeds. It's essential to map the motor's performance curve against the application's needs. However, this is not a straightforward task. Many users overlook the impact of load variations, which can significantly affect performance.

Reliability and thermal management are often underestimated. Motors can overheat, leading to failure if not adequately cooled. An industry study stated that thermal issues cause about 30% of motor failures. Properly selecting materials and cooling solutions can substantially enhance reliability. Reflecting on these factors is vital for optimal motor selection.

When selecting a brushless motor, it's vital to understand the types available in the market. The three main types are synchronous, stepper, and DC brushless motors. Each serves different applications. Synchronous motors offer high efficiency and performance, ideal for precise tasks. Stepper motors are great for applications requiring accurate positioning. They excel in robotics and CNC machines. DC brushless motors provide high speed and durability, suitable for continuous use.

Tips: Consider the torque and speed requirements of your application. Measure the space available for the motor. High performance may come at a higher cost. Finding the right balance is crucial.

Another aspect to consider is the control method. Some motors require complex controllers, while others operate simply. Advanced systems may offer more features, but they can complicate your setup. Think about ease of use as well. A simpler control system might save you time and frustration.

Each type has its benefits and drawbacks. Reflect on your specific needs before making a decision. Test different options if possible. Sometimes, what seems ideal may not fit your requirements perfectly. Evaluate the motor's performance in real-time situations. This ensures you make an informed choice.

When selecting an industrial brushless motor, reliability is a key factor. A robust motor lasts longer and reduces downtime. It’s vital to assess the operating conditions it will face. Consider factors like temperature, humidity, and potential exposure to dust or vibrations. Each of these elements can impact motor performance and lifespan.

Maintenance cannot be overlooked. Brushless motors typically require less upkeep than their brushed counterparts. However, that doesn’t mean they are maintenance-free. Check the motor regularly. Look for signs of wear or unusual noises. Even the best motors may need occasional servicing. This minimizes the risk of unexpected failures.

In practice, users often underestimate the importance of proper installation. An improperly aligned motor can lead to premature wear. Pay attention to alignment and mounting. If possible, consult guidelines from experts. This proactive approach can save time and resources in the long run.