Choosing a suitable Pmdc Motor can significantly impact your project’s success. Many factors must be considered. The design, application, and size of the motor matter. A Pmdc Motor provides efficiency and reliability, making it popular in various fields.

When selecting a Pmdc Motor, think about the specific needs of your project. Are you working in robotics, automation, or another area? Each application has distinct requirements. For instance, motors for precise control may differ from those for heavy loads.

Inadequate research can lead to poor performance or even project failure. Don't overlook the importance of torque, speed, and power ratings. An informed choice can prevent costly mistakes. Keep in mind that every project has unique demands. Your choice of a Pmdc Motor should align with your specific goals and constraints.

PMDC motors, or Permanent Magnet Direct Current motors, are widely used in various applications due to their efficiency and simplicity. These motors generate a magnetic field using permanent magnets, making them easy to control. They are a popular choice for robotics, electric vehicles, and industrial machinery. Their ability to provide high torque at low speeds is particularly beneficial in these fields.

When choosing a PMDC motor, consider factors like voltage, size, and power requirements. Each project has unique needs. A suitable motor must match these specifications. Pay attention to the operating environment as well. Heat and humidity can impact performance. You may need a motor designed for specific conditions, which can complicate the choice process.

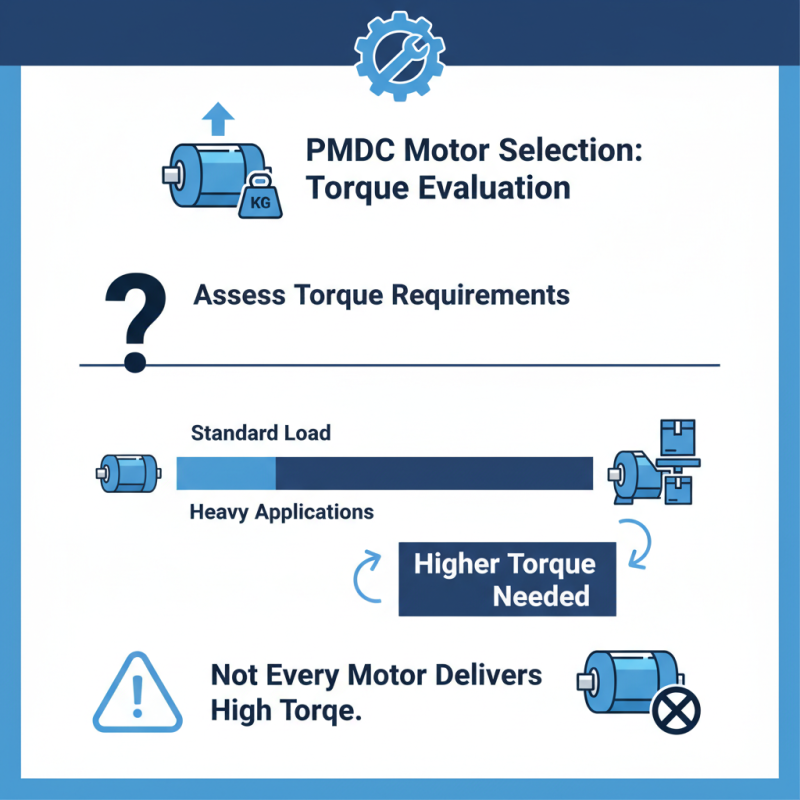

Many overlook the importance of torque and speed. Sometimes, people choose a motor based solely on power ratings. This approach can lead to inefficiencies or even equipment failure. Testing several motors may yield better results. Reflections on past projects can also guide your selection process. Understanding the interplay of these factors is crucial for optimizing your design.

| Motor Type | Voltage (V) | Current (A) | Power (W) | Speed (RPM) | Torque (Nm) | Application |

|---|---|---|---|---|---|---|

| Standard PMDC | 12 | 3.5 | 42 | 3000 | 0.13 | Robotics |

| High Torque PMDC | 24 | 7.0 | 168 | 2000 | 0.25 | Conveyor Systems |

| Miniature PMDC | 6 | 1.0 | 6 | 5000 | 0.02 | Consumer Electronics |

| Industrial PMDC | 48 | 10.0 | 480 | 1500 | 0.6 | Manufacturing Equipment |

| Low Voltage PMDC | 3 | 0.5 | 1.5 | 6000 | 0.01 | Toys and Models |

When selecting a PMDC motor, key specifications are paramount.

Voltage rating is critical. Ensure it matches your power supply. A mismatch can lead to poor performance or damage. Understanding the torque requirements is equally important. Calculate the torque needed for your application. This ensures the motor functions effectively under load.

Tips: Check the motor's efficiency rating. A high-efficiency motor conserves energy. Consider the physical dimensions of the motor. It should fit within the design constraints of your project.

Another aspect to ponder is speed. Choose a motor that operates at the desired speed. If the speed is too low, it may not meet application needs. Also, think about duty cycle. Continuous use may require a different motor compared to intermittent use.

Tips: Research cooling options for motors working under high loads. Overheating can drastically reduce lifespan. It's beneficial to leave some margin in your specifications for future scalability.

When selecting a PMDC motor for your project, performance evaluation is crucial. Start by assessing torque requirements. Torque defines how well the motor can handle load. Higher torque may be necessary for heavy applications. Remember, not every motor can meet high torque demands effectively.

Next, consider speed specifications. Different projects require varied speeds. Some tasks need fast rotations, while others require precision. A motor's maximum RPM is key. Ensure the model you’re looking at can reach the desired speed consistently. However, balance is vital. A high-speed motor may lack torque, leading to inefficiency.

Another factor is efficiency ratings. Motors waste energy when they overheat or draw too much current. Look for motors with good heat management. A more efficient motor translates into better performance and longer life. Sometimes, choosing the cheapest option may lead to regrets. Not all affordable motors deliver on their promises. An ideal motor should be scalable to future needs too. Consider these aspects carefully when making your choice.

When selecting a PMDC motor, cost-effectiveness is key. Different PMDC motors have varying price points. It's not just about initial costs. The long-term efficiency can make a significant difference. You may find cheaper options upfront. However, they may require more maintenance or replacement. This could lead to higher costs over time.

Evaluate the efficiency ratings of various models. A more efficient motor may have a higher purchase price but could save money on electricity. Look into user reviews and performance reports. These details can highlight potential issues. Not every motor delivers as promised, even if it looks good on paper.

Don't forget to consider the application. A motor that works well in one project might not suit another. Sometimes, the most cost-effective option isn’t the one that seems the best at first glance. Balancing initial costs with expected performance is crucial. Test both options before making a final choice, if possible. This can lead to better project outcomes.

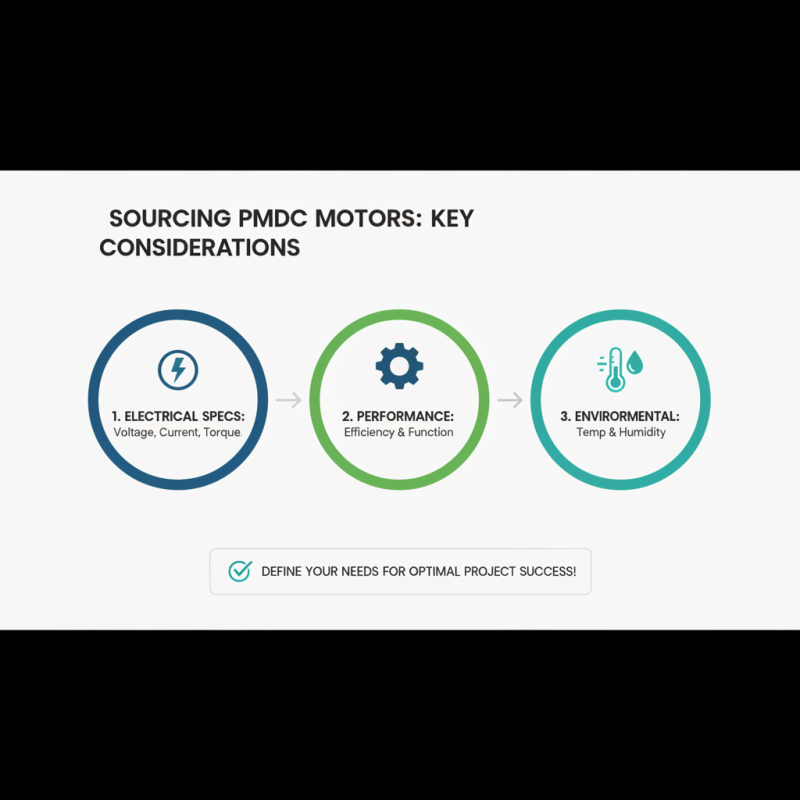

When sourcing PMDC motors for your project, understanding your specific needs is crucial. Identify parameters like voltage, current, and torque. Each specification impacts performance and efficiency. Don't overlook operational environment factors, too. For example, temperature and humidity can affect motor function.

Tip: Create a detailed list of requirements. This will help you narrow down your options. Avoid getting overwhelmed by too many choices. Focus on parameters that matter for your application.

Consider the supplier's reputation. Reading reviews can help you gauge their reliability. Engage with them about your project. Responsive communication can be a good sign. Remember, a lower price doesn't always mean better value. Sometimes, it’s worth spending more for quality.

Tip: Think about the long-term implications of your choice. Will the motor still meet your needs in a few years? Reflect on this aspect carefully. The right PMDC motor can make a significant difference in your project’s success.