DC brushless motors have gained immense popularity in various industries due to their efficiency and reliability. According to a recent report by MarketsandMarkets, the global market for DC brushless motors is expected to reach $30 billion by 2026, highlighting their growing significance. As industry expert Dr. Emily Carter stated, "DC brushless technology is revolutionizing the way we think about motor design."

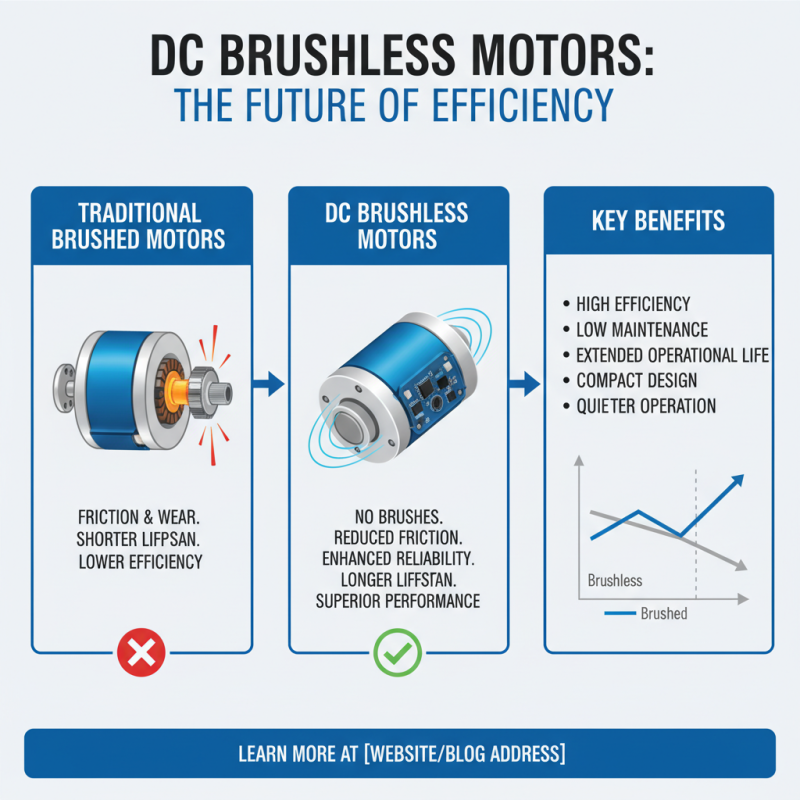

These motors operate without brushes, reducing friction and wear. This feature extends their lifespan and enhances performance. Many applications utilize DC brushless motors, from electric vehicles to household appliances. The efficiency of these motors leads to lower energy consumption and operational costs.

However, the technology is not without its challenges. The initial cost can be higher than traditional motors. Users must weigh these factors carefully. Overall, understanding the mechanics of DC brushless motors can lead to better decision-making in selecting the right motor for specific applications.

DC brushless motors are increasingly popular in various applications. They are known for their high efficiency and reliability. Understanding the basics of these motors can help you appreciate their benefits.

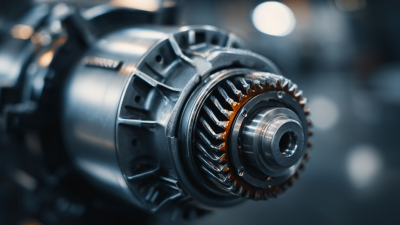

One key feature of a DC brushless motor is its lack of brushes. This design minimizes wear and tear, leading to a longer lifespan. Instead of mechanical brushes, these motors use electronic controllers. This allows for smoother operation and precise control over speed and torque. The absence of brushes also reduces electrical noise, making them ideal for sensitive applications.

**Tips:** When selecting a DC brushless motor, consider the load requirements. It's crucial to match the motor's specifications with your project needs. Pay attention to the power supply as well. An inadequate supply can lead to performance issues.

Keep in mind that while DC brushless motors offer many advantages, they can be more complex than their brushed counterparts. Maintenance may still be necessary, especially in intricate systems. It's essential to evaluate your design requirements carefully. Fine-tuning your setup can lead to significant efficiency gains.

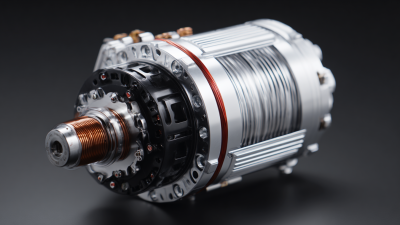

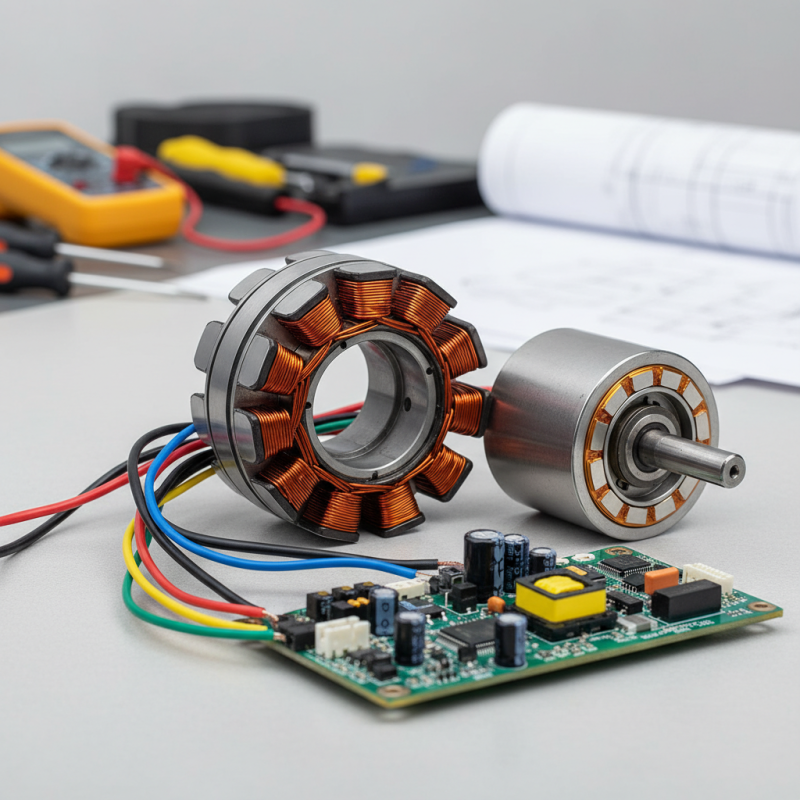

A DC brushless motor consists of several key components that allow it to operate efficiently. The main parts include the

stator, rotor, electronic controller, and

Hall sensors. The stator is typically made of

stacked laminations to reduce energy losses. It creates a

magnetic field when electricity flows through it.

This design improves performance by minimizing heat generation.

The rotor houses permanent magnets and rotates within the magnetic field created by the stator. Unlike brush motors,

the absence of brushes in a brushless motor eliminates mechanical wear. This improves the lifespan of the motor.

According to a recent industry report, brushless motors exhibit efficiency ratings of

over 90%. This contrasts sharply with brushed motors, which often struggle

to exceed 75% efficiency.

Electronic controllers play a critical role in operating a DC brushless motor. They manage the power supply and control

the speed and torque of the motor. Hall sensors provide feedback on the rotor's

position, ensuring precise timing in the motor’s operation. However, the complexity of these systems can lead to

potential failures. Regular maintenance is crucial to address these issues;

neglecting it can result in performance drops and electrical failures.

DC brushless motors are gaining popularity due to their efficiency and reliability. These motors operate on a principle that combines electromagnetism and electronic control. Unlike traditional motors, DC brushless ones don't have brushes, which reduces friction and wear. This design improves lifespan and performance.

The basic operating principle involves a permanent magnet rotor and a stator with coils. When the motor receives a DC supply, the controller activates the coils in a sequence. This generates a magnetic field that interacts with the rotor. The result? Continuous rotation. According to industry reports, brushless motors can achieve efficiencies of up to 90%. This is a significant improvement over brushed motors, where efficiency often falls between 70-80%.

Tips: Choose the right driver for your motor. A mismatched controller can lead to performance issues. Moreover, regular maintenance and monitoring are key. Keep an eye on temperature levels. Overheating can result in failure.

While DC brushless motors are efficient, they have potential drawbacks. They require complex control systems. That adds to costs and complexity in design. Additionally, their initial price can be higher than brushed counterparts. Many companies look for cost-effective solutions and may overlook these technicalities. Balancing cost and performance is crucial.

DC brushless motors are gaining popularity due to their numerous advantages. One significant benefit is their high efficiency. They convert more electrical energy into mechanical energy than traditional brushed motors. This results in lower energy consumption and longer battery life in applications like electric vehicles and drones.

Another advantage is reduced maintenance. Without brushes, these motors experience less wear and tear. This translates to fewer breakdowns and lower maintenance costs. Users can save time and money on repairs.

Tip: Always check the motor’s specifications for compatibility with your application. It’s crucial to ensure the motor’s power rating meets your needs.

Moreover, DC brushless motors are quieter. The absence of brushes and commutators reduces noise levels. This feature is particularly valuable in household appliances or medical devices, where quiet operation is essential.

However, it's important to consider the initial cost. Brushless motors are often more expensive to manufacture. Some users may hesitate to invest upfront. Balancing performance with budget is vital.

Tip: Consider long-term savings when evaluating motor costs. The efficiency and reduced maintenance can offset the higher initial price over time.

DC brushless motors are widely used in various sectors due to their efficiency and reliability. In the automotive industry, for example, they power electric vehicles and hybrid systems. A report from the International Energy Agency states that electric vehicle sales were predicted to exceed 20 million by 2025. This surge relies significantly on efficient motor technologies.

In the consumer electronics sector, brushless motors drive devices like drones and computer cooling systems. According to a market research report, the global consumer drone market is expected to reach $6.7 billion by 2025. As this demand grows, so does the need for compact, powerful motors that can provide high performance without the hassle of maintenance.

Medical devices also benefit from DC brushless motors. Many advanced equipment, such as imaging systems and robotic surgical tools, leverage these motors for precision. The medical robotics market alone is projected to reach $20 billion by 2024. However, the integration of such technologies comes with challenges. Manufacturers must ensure reliability while minimizing noise and energy consumption. Balancing performance with these factors requires ongoing innovation and reflection on existing practices.