In the rapidly evolving landscape of industrial automation, the efficiency of DC servomotors has emerged as a pivotal area of exploration, directly influencing the performance and reliability of various applications. As key components in diverse systems ranging from robotics to CNC machinery, DC servomotors are celebrated for their precision control and adaptability. This article delves into the crucial metrics that define their efficiency, including torque characteristics, speed response, and energy consumption. By assessing these parameters, we aim to uncover the best practices in the selection and implementation of DC servomotors across different industries. From enhancing productivity to minimizing operational costs, understanding the efficiency of these motors is essential for engineers and manufacturers alike. Through a comprehensive analysis of current trends and technological advancements, this exploration not only highlights the significance of DC servomotors but also positions them as vital assets in the drive towards smarter and more efficient industrial processes.

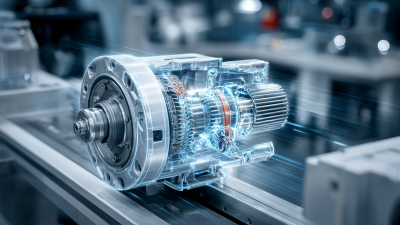

DC servomotors are essential components in a variety of industrial applications, providing precise control of angular position, velocity, and acceleration. At their core, these motors consist of key components: the stator, rotor, commutator, and brushes. The stator generates a magnetic field, while the rotor rotates within this field, converting electrical energy into mechanical energy. Modern advancements have led to the development of brushless DC motors, which eliminate the need for brushes, improving efficiency and reducing wear. According to a report by MarketsandMarkets, the global DC motor market is projected to reach $11.5 billion by 2025, driven by rising demand in sectors such as automotive and robotics.

When selecting a DC servomotor for a specific application, it's crucial to consider metrics such as torque-to-weight ratio and responsiveness. Generally, motors with a higher torque-to-weight ratio can handle greater loads with less energy consumption. Furthermore, proper sizing of the motor will enhance system performance while prolonging lifespan.

Tips: Always account for thermal management in servomotor applications. Excessive heat can reduce efficiency and lead to premature failure. Additionally, consider using encoders for feedback control, as they provide real-time data on the motor's position, enabling more accurate movements.

In the realm of DC servomotors, performance metrics such as torque, speed, and efficiency are fundamental in determining their operational effectiveness in various applications. Recent advancements highlight the significance of precision control systems, notably the implementation of high-precision adaptive neuro fuzzy inference controllers for DC motor drives that manage speed through a dual Proportional-Integral (PI) controller framework. Such innovations have been shown to maximize torque output while enhancing speed regulation, which is critical in applications requiring stringent performance parameters.

Moreover, the efficiency of DC motor systems is further optimized by novel control strategies like the multi-stage Fractional Order Proportional-Integral (FOPI) controller, which has demonstrated superior speed control capabilities. Research indicates that employing advanced optimization algorithms, such as the Pelican Optimization Algorithm, can effectively fine-tune the controller parameters, thus improving overall operational efficiency. Additionally, the modified jellyfish search algorithm presents a compelling method for tuning PID controllers, affirming the importance of adaptive control mechanisms in maximizing the operational parameters of DC servomotors in industrial applications. These advancements not only illustrate the dynamic evolution of motor control technology but also underline the necessity for continuous optimization to meet the ever-growing demands of the industry.

DC servomotors play a pivotal role in driving automation across various sectors, particularly in manufacturing and robotics. According to the Integrated Servo Motor Market report, the demand for DC servomotors is projected to grow significantly due to their efficiency and precision in control applications. Key metrics highlight their ability to enhance torque, speed, and position accuracy while minimizing energy consumption. This efficiency makes them a preferred choice in automated systems, where reliability and performance are crucial.

DC servomotors play a pivotal role in driving automation across various sectors, particularly in manufacturing and robotics. According to the Integrated Servo Motor Market report, the demand for DC servomotors is projected to grow significantly due to their efficiency and precision in control applications. Key metrics highlight their ability to enhance torque, speed, and position accuracy while minimizing energy consumption. This efficiency makes them a preferred choice in automated systems, where reliability and performance are crucial.

In the automotive industry, DC servomotors are integral for applications such as robotics in assembly lines, where they facilitate seamless operations and improve production rates. Industries are increasingly integrating these motors into robotics due to their adaptability to various control systems and straightforward implementation in high-precision tasks. Furthermore, insights from the Electric Motor Import List 2025 reveal that the global market for electric motors, including DC types, is expanding, with key buyers focusing on sourcing advanced technologies to remain competitive in automation and innovate their manufacturing processes.

DC servomotors have become a focal point in various industries, particularly when comparing their efficiency against AC servomotors. Recent market analyses reveal that the Micro Motor Market is projected to exceed USD 81.37 billion by 2032, growing at a CAGR of 7.30%. This growth is driven by the demand for compact and high-efficiency motors across sectors such as automotive, healthcare, robotics, and consumer electronics. In this landscape, DC servomotors offer distinct advantages, particularly in applications requiring precise control and quick response times.

The integrated servo motor market further highlights the relevance of both AC and DC motors, with segmentation by type showing significant interest in their respective capabilities. Reports indicate that digital servo motors and drives are expected to reach USD 18.5 billion by 2035, indicating a solid adoption trend fueled by digital transformation and automation. As industries increasingly embrace automation, the comparison between DC and AC servomotors becomes critical, with each type catering to specific operational needs and efficiency parameters in diverse applications.

| Metric | DC Servomotor | AC Servomotor | Industry Applications |

|---|---|---|---|

| Efficiency | 85-90% | 80-85% | Robotics, CNC Machines |

| Torque Characteristics | High starting torque | Constant torque | Automotive, Conveyor Systems |

| Speed Control | Precise and smooth | Moderate | Textile, Packaging |

| Maintenance | Requires more maintenance | Low maintenance | HVAC, Pumping |

| Cost | Higher initial cost | Lower initial cost | Manufacturing, Assembly |

The future of DC servomotor technology is poised for significant advancements, driven by the continuous pursuit of higher efficiency, precision, and reliability. Emerging innovations in materials science are leading to lighter and stronger components that can withstand higher operating temperatures and improve overall performance. Additionally, the integration of smart technologies, such as IoT sensors and AI algorithms, is enabling real-time monitoring and control, which enhances the responsiveness and adaptability of DC servomotors in various applications.

Moreover, the trend towards electrification in industries such as automotive and robotics is accelerating the development of advanced DC servomotors. As electric vehicles (EVs) become more prevalent, the demand for smaller, more efficient motor solutions is increasing. Innovations such as brushless designs and permanent magnet technologies are enhancing torque density and minimizing maintenance requirements. These developments not only optimize performance but also contribute to sustainability efforts by reducing energy consumption and emissions in industrial processes. As these trends continue, DC servomotors are expected to play a crucial role in shaping the future of automation and smart manufacturing.

This chart illustrates the efficiency of DC servomotors across various applications. It highlights the efficiency percentages in different sectors, providing insight into how advancements in technology are influencing performance standards.