In the quest for enhanced energy efficiency and performance in various applications, Permanent Magnet DC Motors (PMDC) have emerged as a pivotal technology. This innovative type of motor harnesses the power of permanent magnets to create a consistent and reliable magnetic field, resulting in superior torque and speed characteristics compared to traditional motors. As industries increasingly pivot towards automation and electric systems, the demand for PMDC motors has surged, with their unique advantages making them suitable for a wide range of applications, from automotive to robotics. This article delves into the science behind Permanent Magnet DC Motors, exploring their operational principles, key advantages, and the latest advancements driving their adoption in modern technology. By understanding the mechanics of PMDC motors, we can unlock new efficiencies and capabilities that are essential for the future of industrial and consumer applications.

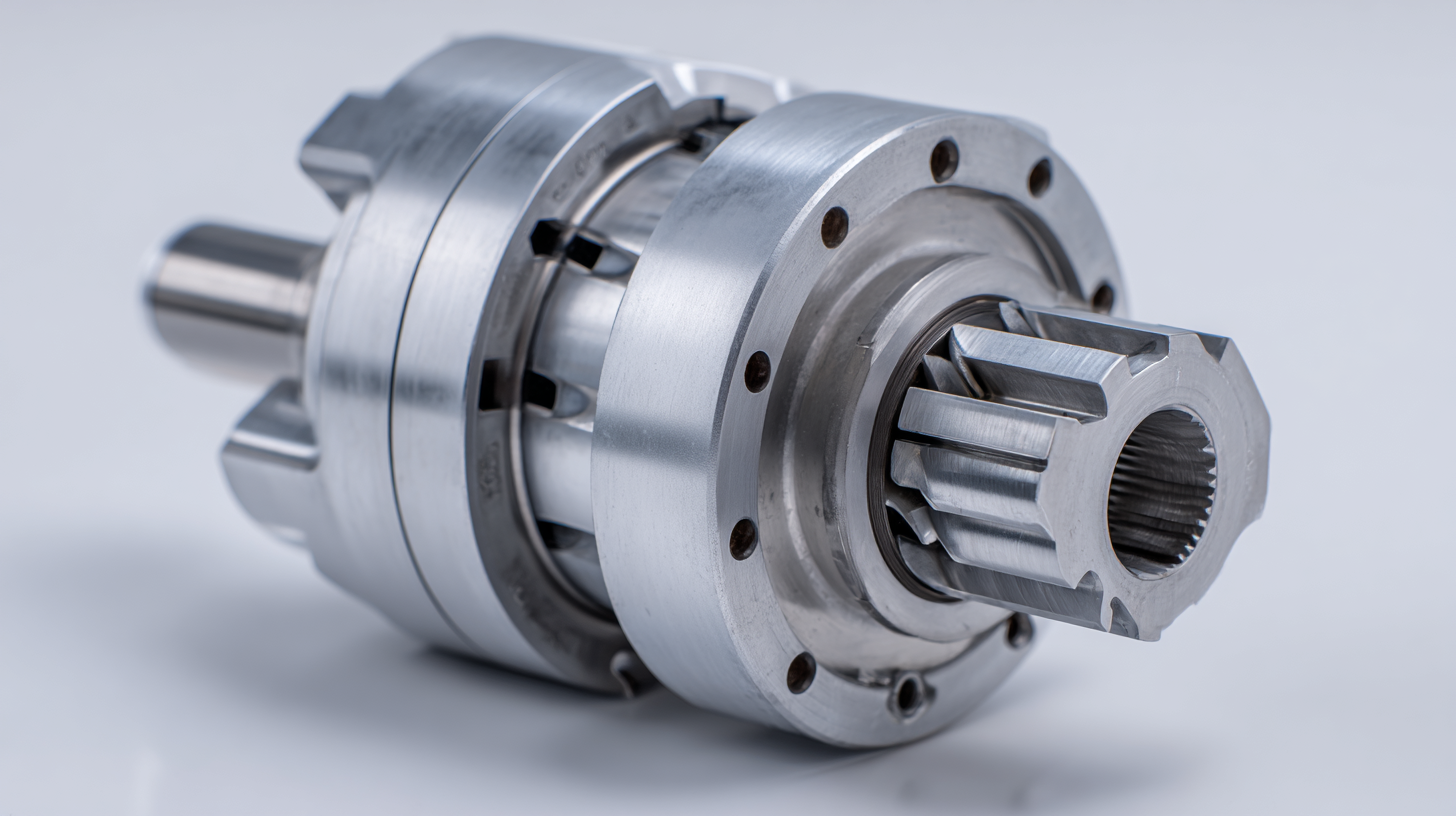

Permanent Magnet DC (PMDC) motors have gained widespread popularity due to their efficiency and compact design. There are several types of PMDC motors, each with distinct characteristics that suit various applications. The most common include separately excited, shunt-wound, and series-wound PMDC motors. Separately excited motors allow for better speed control as the field winding is independent of the armature circuit, making them ideal for applications requiring precision. In contrast, shunt-wound motors provide a stable speed under varying loads, making them suitable for constant-speed applications such as fans and pumps. Series-wound motors, on the other hand, deliver high starting torque, making them perfect for applications like cranes and electric vehicles.

**Tip 1:** When selecting a PMDC motor, consider the specific speed and torque requirements of your application to choose the appropriate type.

In addition to their specific characteristics, PMDC motors are renowned for their ease of maintenance and reliability. Their simple construction eliminates the need for brushes in certain varieties, which can significantly reduce wear and operational costs. Understanding the motor's thermal and load characteristics is crucial for optimizing performance and extending lifespan.

**Tip 2:** Regularly monitor the operating temperature and load conditions of your PMDC motor to ensure it functions efficiently and maintains longevity.

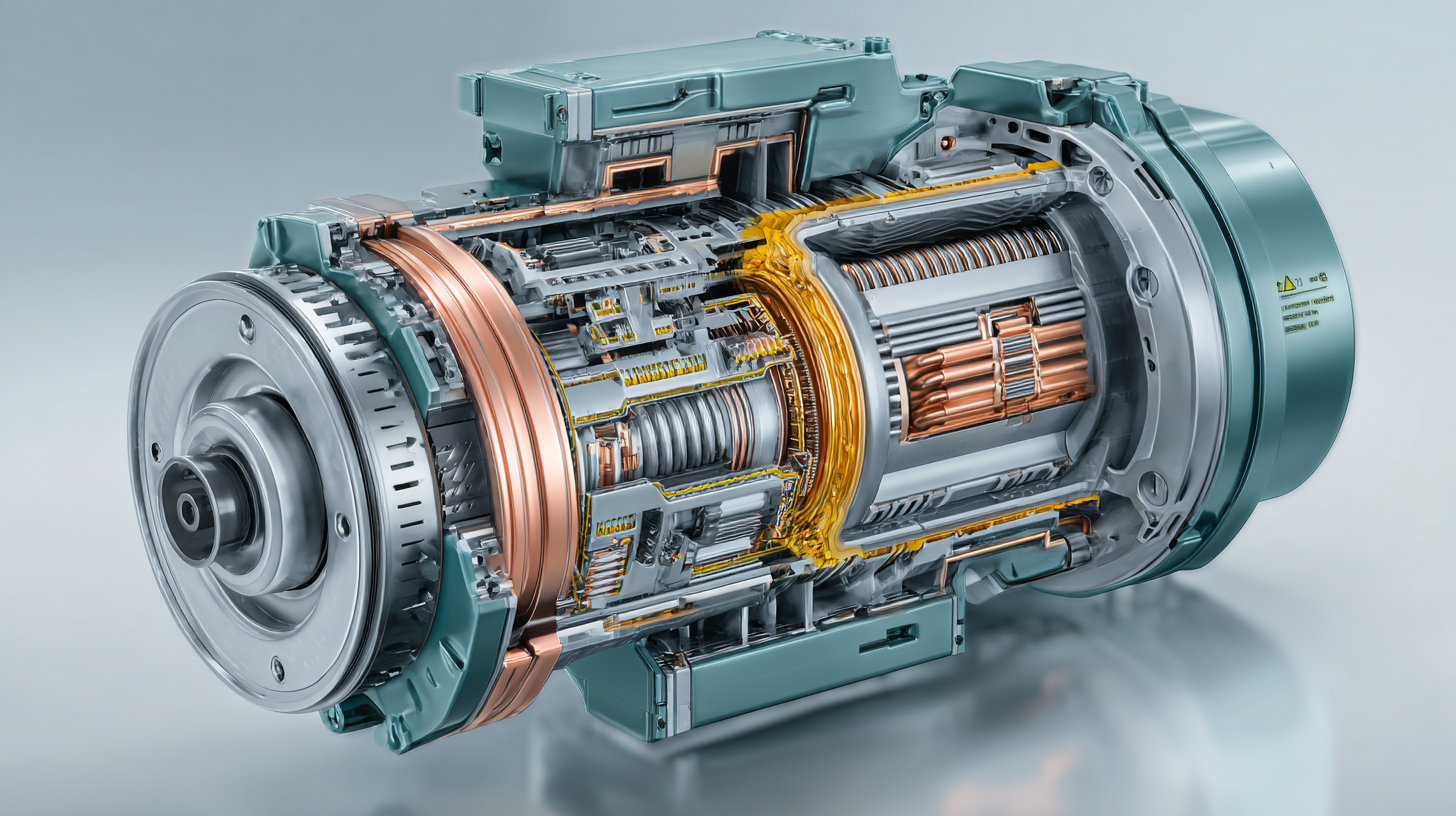

When evaluating the efficiency of various DC motors, Permanent Magnet DC (PMDC) motors stand out for their superior performance in comparison to other types, such as brushed and brushless DC motors. According to a report by Allied Market Research, the global PMDC motor market is projected to reach $27.7 billion by 2025, driven by their increasing adoption in automotive and industrial applications due to their compact size and high torque-to-weight ratios. In contrast, traditional brushed DC motors tend to experience a decrease in efficiency as the brushes wear down, resulting in increased maintenance costs and lower overall performance.

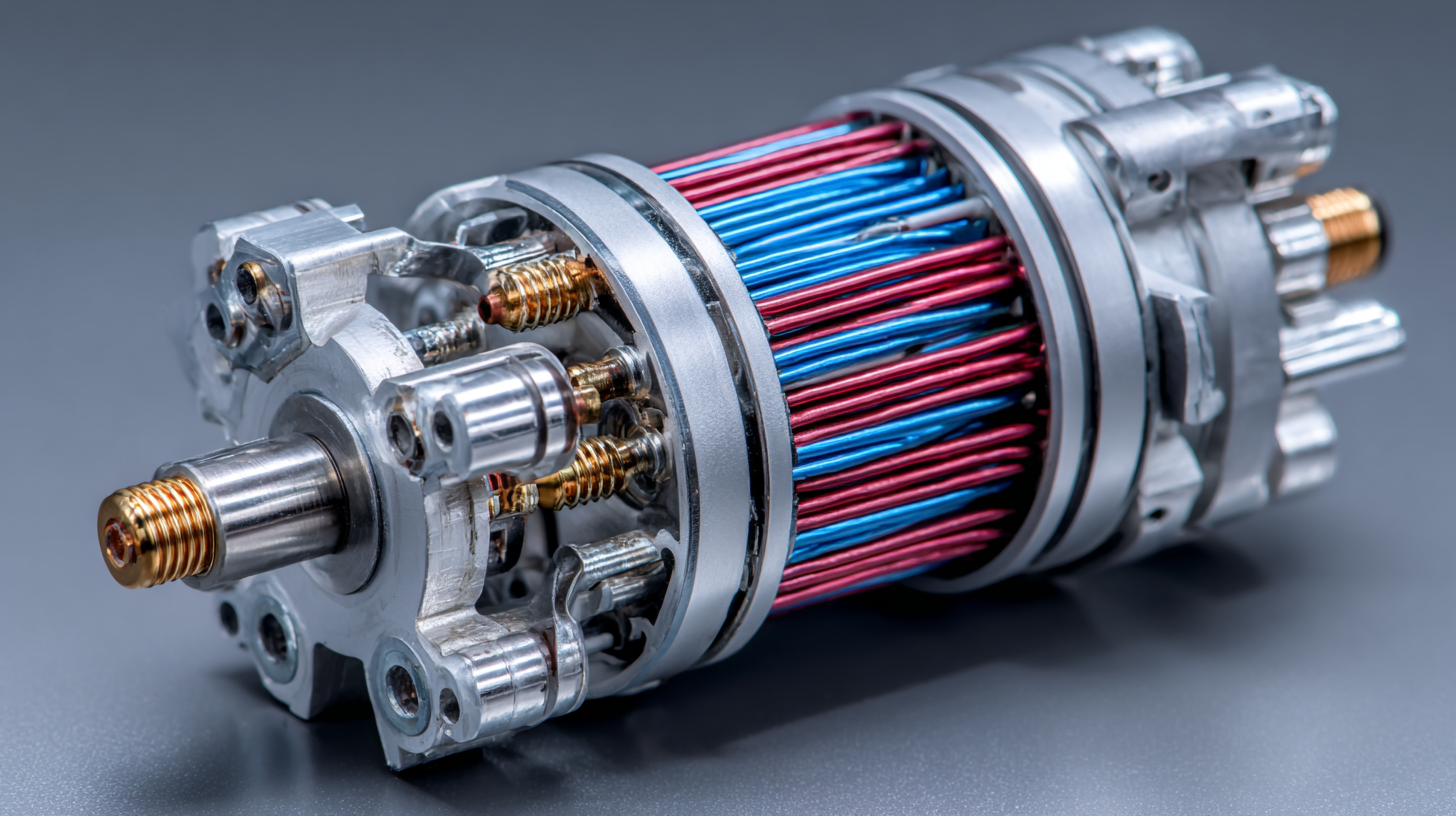

One key factor in the efficiency of PMDC motors is their inherent design, which eliminates the need for brush and commutator systems. This not only minimizes energy losses but also enhances operational lifespan. A study conducted by Robotics and Automation Magazine found that PMDC motors can achieve efficiencies of up to 90%, compared to only 70-80% for brushed DC motors. For those looking to maximize performance in applications like robotics or electric vehicles, the choice of motor can significantly impact the energy consumption and longevity of the system.

Tips: When selecting a motor for your application, consider the specific power requirements and duty cycle. PMDC motors are ideal for high-performance tasks and short durations, while brushed motors may suffice for lower-demand applications. Additionally, evaluate the long-term costs including maintenance and energy use to determine the best fit for your needs.

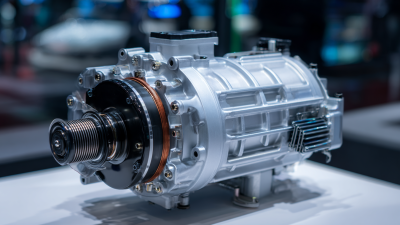

Permanent Magnet DC (PMDC) motors are increasingly gaining traction across various industries due to their high efficiency and compact design. Their applications range from electric vehicles (EVs) to renewable energy systems and industrial machinery. In the automotive sector, the transition towards more sustainable transportation has led to a re-evaluation of traditional motor technologies. While Permanent Magnet Synchronous Motors (PMSMs) and AC Induction Motors (ACIMs) have been prominent, PMDC motors are emerging as viable alternatives, particularly in lower-power applications where their lightweight and efficient characteristics can be fully utilized.

Tips: When considering PMDC motors for your project, assess the application requirements such as torque and operational speed to ensure optimal performance. Additionally, keep sustainability in mind by exploring options that align with efficiency standards like IEC 60034-30 and NEMA requirements, which can further enhance performance while minimizing energy consumption.

Furthermore, the water sector exemplifies the push for innovation and sustainability, integrating electric motors that not only optimize energy usage but also meet rigorous efficiency standards. As industries adopt PMDC motors, it’s essential to stay informed about advancements in technology and efficiency regulations to harness their full potential. Adopting these motors can lead to significant savings and improvements in overall system performance.

Permanent Magnet DC (PMDC) motors have become increasingly vital in modern technological applications due to their numerous advantages. One significant benefit is their high efficiency. Because these motors utilize permanent magnets rather than electrical windings for the magnetic field, they can achieve higher torque and faster speeds with lower energy consumption. This efficiency not only reduces operational costs but also contributes to a smaller carbon footprint, making PMDC motors an eco-friendly choice for various devices, from electric vehicles to household appliances.

Another advantage is their compact design and lightweight structure. PMDC motors can deliver substantial power output in a smaller size, allowing manufacturers to create more versatile and space-saving products. This feature is particularly beneficial in applications like robotics and portable electronics, where size and weight constraints are critical.

Tips: When selecting a PMDC motor for a project, consider the specific torque and speed requirements. Always assess the motor’s thermal management capabilities, as efficient cooling is essential for maintaining performance and longevity. Lastly, ensure compatibility with your power supply to maximize the motor's efficiency and lifespan.

The implementation of Permanent Magnet DC (PMDC) motors offers several advantages, including high efficiency and a compact design. However, these benefits come with notable challenges that can limit their application in certain environments. One primary concern is the sensitivity of PMDC motors to temperature variations. As temperature rises, the performance of the magnets can degrade, leading to reduced efficiency and potential failure. This sensitivity demands careful thermal management in design and operation, especially in industries where operating conditions can fluctuate dramatically.

Another challenge lies in the cost and availability of high-quality permanent magnets, typically made from rare-earth materials. These materials can be prone to price volatility and supply chain issues, impacting the overall cost-effectiveness of PMDC motors. Additionally, the magnetic properties of these materials can diminish over time, especially in high-stress applications, potentially necessitating costly replacements or repairs. Furthermore, the reliance on these magnets can limit the operational ranges, affecting the adaptability of PMDC motors in diverse applications, from robotics to automotive technologies.

As a result, while PMDC motors demonstrate remarkable efficiency, addressing these limitations is crucial for broader implementation in various engineering fields.