Choosing the right DC torque motor for your project can be a daunting task, especially given the multitude of options available on the market today. DC torque motors are essential components in various applications that require precise control of rotational movement and consistent torque output. Whether you're working on a robotics project, an automation system, or any machinery where reliability and efficiency are paramount, understanding the key factors that influence your selection of a DC torque motor is crucial.

In this guide, we will explore ten essential tips that will help you navigate the important considerations involved in the selection process. From understanding your project’s specific torque and speed requirements to evaluating the motor's efficiency and durability, these tips will provide you with the knowledge needed to make an informed decision. By focusing on the various parameters that define a DC torque motor’s performance, you can ensure that the motor you choose will meet the demands of your application and contribute to the overall success of your project.

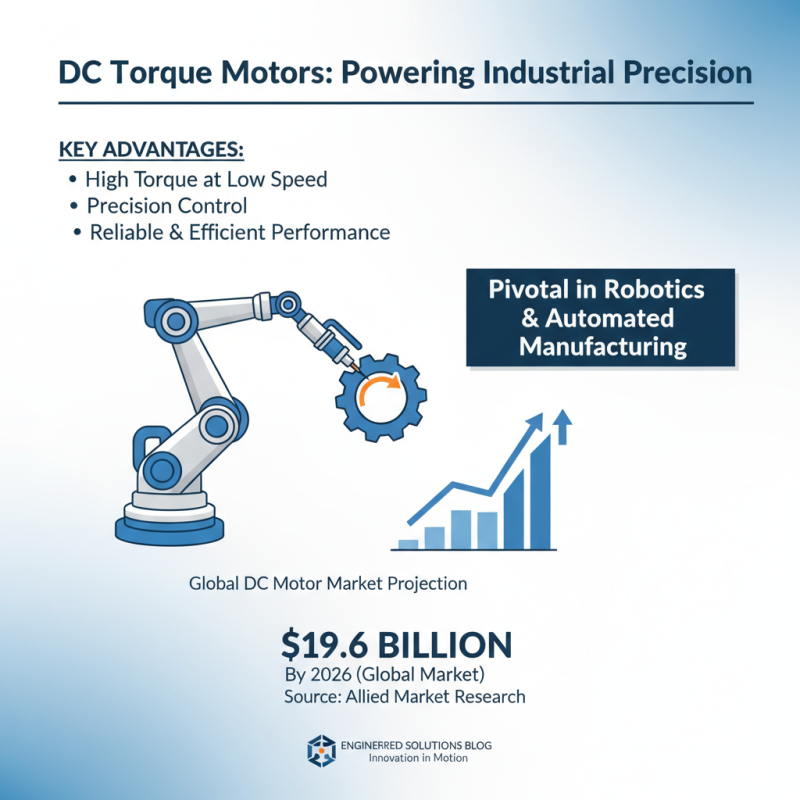

DC torque motors are pivotal in various industries, providing reliable and efficient performance for applications ranging from robotics to automated manufacturing. These motors excel in delivering high torque at low speeds, making them ideal for tasks requiring precision control. According to a recent industry report by Allied Market Research, the global market for DC motors is projected to reach $19.6 billion by 2026, highlighting their growing importance in modern engineering projects.

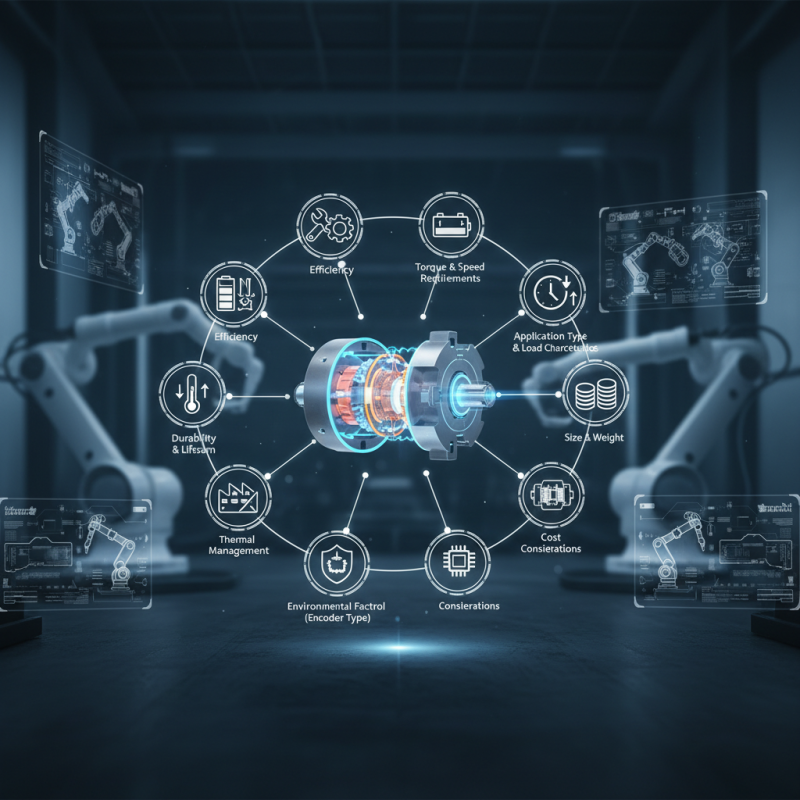

When considering the right DC torque motor for your project, it's crucial to assess several key factors. One essential tip is to evaluate your specific application requirements, such as load capacity and operational speed. This ensures you select a motor that can handle the demands of your task. Additionally, understanding the voltage and current specifications is vital, as mismatched requirements can lead to inefficient performance or potential damage.

Another important aspect to consider is the motor's efficiency rating. Higher efficiency can reduce energy costs and enhance the overall performance of your project. It's also wise to examine the torque-speed curve of the motor to better understand its operational characteristics. Properly matching these elements to your project's needs can lead to significant improvements in efficiency and functionality.

When selecting a DC torque motor for your project, it’s crucial to understand the key factors that will influence your decision. First, you need to determine the required torque and speed specifications. The performance characteristics of the motor must align with the demands of your application, whether it’s a robotic arm, conveyor system, or any other mechanism requiring precise motion. Calculating the load conditions and understanding the relationship between torque and speed will help ensure that you choose a motor capable of meeting your operational needs.

Another important consideration is the size and weight of the motor. Assess the available space in your project and weigh the benefits of a compact motor versus a more powerful, larger option. Balance between power requirements and physical constraints will play a significant role in system integration. Additionally, think about the operating environment—if the motor will be exposed to dust, moisture, or variable temperatures, you may need to opt for models that offer protective features.

Tip: Be mindful of the motor's efficiency and power consumption. Selecting a motor that operates efficiently can lead to lower operational costs over time. Also, consider the type of feedback mechanism you may require, such as encoders for precise positioning, as this can enhance the performance and reliability of your overall system. Making informed choices about these factors will set a solid foundation for your project's success.

When selecting a DC torque motor for your specific application, understanding the required specifications is critical to ensure optimal performance and efficiency. One of the primary considerations is the torque output needed for your project. According to the International Electrotechnical Commission (IEC), the torque requirements can vary significantly based on the load conditions and operational speed. It’s essential to accurately calculate the static and dynamic torque needed, as underestimating these requirements can lead to motor failure or inadequate performance.

Another key specification to evaluate is the voltage and current ratings of the motor. Industry reports from the Electric Motor Association (EMA) indicate that improper voltage selection can lead to inefficiencies, potential overheating, and reduced lifespan of the motor. The relationship between voltage and torque must be understood, as higher voltage can facilitate greater torque output, but may also require additional considerations for motor design and system compatibility.

Additionally, pay attention to factors such as duty cycle, which impacts the overall thermal management of the motor and its ability to operate under sustained loads, helping to prevent thermal overload and ensuring safe operation. Understanding these parameters will significantly enhance your ability to select the most suitable DC torque motor for your application.

When selecting a DC torque motor for your project, it's crucial to understand the different types available to ensure optimal performance. The two main categories are brushed and brushless DC motors. Brushed motors are known for their simple design and cost-effectiveness, making them a popular choice for applications requiring moderate power and torque. However, they may require more maintenance due to the wear and tear of brushes over time. These motors are often used in simpler applications such as hobbyist projects or small mechanical devices.

On the other hand, brushless DC motors, though typically more expensive, offer significant advantages in efficiency and lifespan. Their design minimizes friction and heat generation, making them ideal for demanding applications where reliability and performance are critical. Brushless motors also provide smoother operation and better torque control, which can be advantageous in robotics and automation. When deciding between these options, consider the specific requirements of your project, such as power needs, space constraints, and budget, to determine the most suitable DC torque motor type for your application.

| Motor Type | Torque (Nm) | Voltage (V) | Speed (RPM) | Efficiency (%) | Size (mm) |

|---|---|---|---|---|---|

| Permanent Magnet Motor | 0.5 | 24 | 3000 | 85 | 45x45 |

| Brushed DC Motor | 1.0 | 12 | 6000 | 75 | 40x40 |

| Brushless DC Motor | 2.5 | 36 | 2000 | 90 | 50x50 |

| Coreless DC Motor | 0.15 | 9 | 8000 | 80 | 25x30 |

| Step Motor | 0.6 | 48 | 100 | 70 | 60x60 |

When budgeting for your DC torque motor project, understanding the costs involved is essential for staying on track and achieving your goals. According to a report by the Global Market Insights, the DC motor market is expected to reach $25 billion by 2026, driven primarily by advancements in technology and rising demand across various industries. This growth highlights the importance of carefully considering both the initial investment and long-term operational costs associated with your motor selection.

One of the key factors impacting costs is the varying price range of DC torque motors, which can typically vary from $100 to over $1,000, depending on specifications like power output, torque ratings, and efficiency levels. In addition to the motor itself, potential expenses can arise from peripherals such as controllers and gearboxes, which can add an extra 20-30% to your overall budget. To mitigate expenses, exploring alternatives such as second-hand motors or customized solutions can provide significant savings while still meeting project requirements. Systematic planning and diligent research are critical to ensuring that your investment yields the best possible performance and longevity for your application.