In the ever-evolving realm of engineering, selecting the right component can be the make-or-break factor in a project's success. Particularly in applications requiring precision and power, the choice of a High Torque BLDC Motor is critical. Industry expert James Hartman, a leading figure in motor technology, emphasizes, "The efficiency and performance of your project hinge on choosing the appropriate motor; a high torque BLDC motor can make all the difference in achieving optimal results."

The landscape of high torque BLDC motors is vast, presenting a myriad of options that cater to various requirements. Understanding the key facets, from torque ratings to control methods, can empower engineers to make informed decisions. This article distills essential tips that will guide you through the complexities of selecting the right high torque BLDC motor for your project, ensuring you harness the full potential of this innovative technology while achieving seamless performance and durability.

As we delve into these tips, we will highlight best practices that can enhance your selection process, thereby paving the way for successful project execution with the ideal High Torque BLDC Motor.

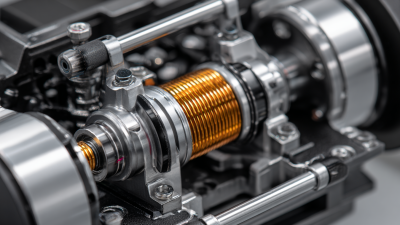

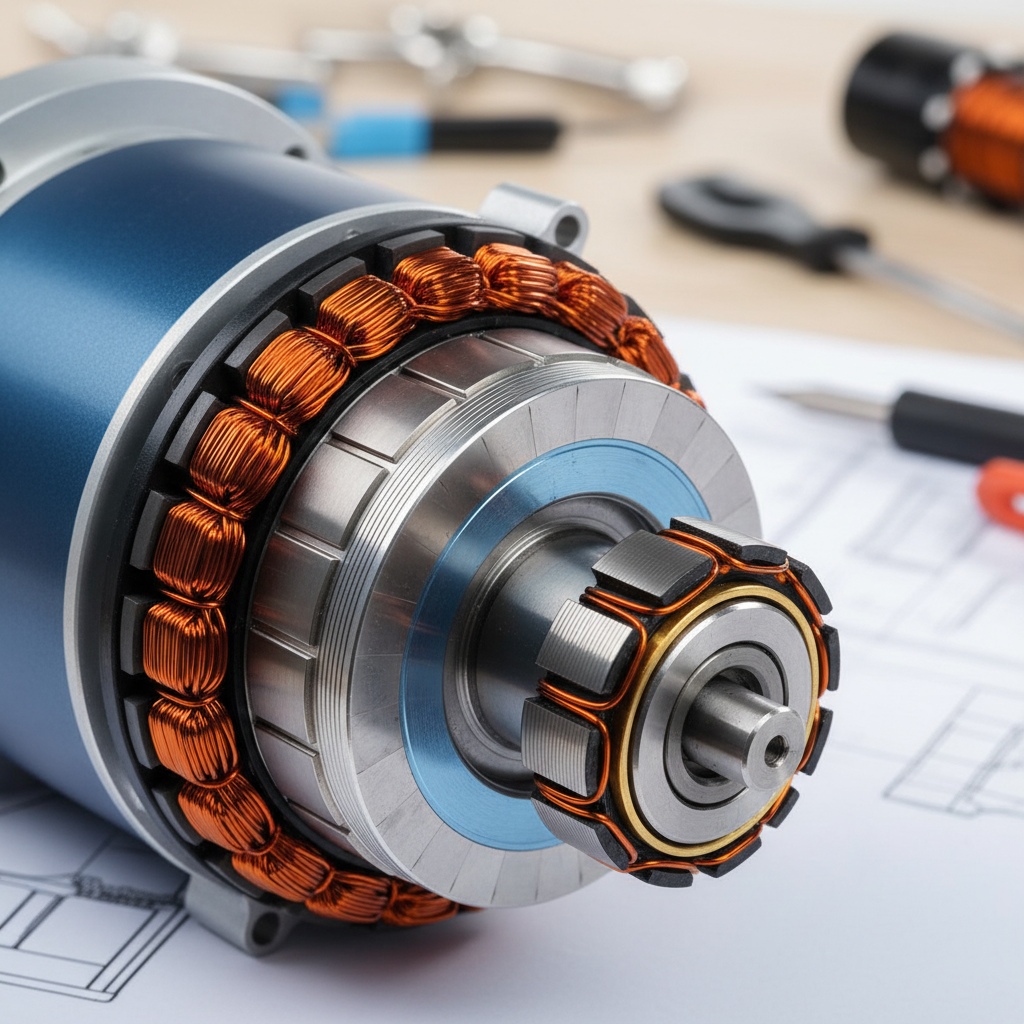

When selecting a high torque Brushless DC (BLDC) motor for your project, it's crucial to understand the fundamental characteristics that define these motors. High torque BLDC motors are known for their efficiency and reliability, making them suitable for various applications, from robotics to electric vehicles. According to the "2022 Global Electric Motor Market Report," the demand for BLDC motors is projected to grow significantly, driven by their superior performance and low maintenance needs, with a CAGR of over 8% expected through 2027.

One of the key attributes of high torque BLDC motors is their ability to deliver high torque at low speeds, which is essential for applications requiring precise control. For instance, a study published in the "Journal of Electrical Engineering" highlights that these motors can provide up to 70% more torque than equivalent brushed motors at the same size and weight. Moreover, their design contributes to a longer lifespan due to reduced wear and lower thermal losses, making them ideal for continuous operation, particularly in industrial settings where performance reliability is paramount.

| Feature | Description | Importance |

|---|---|---|

| Torque Rating | The maximum torque the motor can provide. | Critical for applications requiring high starting torque. |

| Speed Range | Different motors operate efficiently within various RPM ranges. | Ensures the motor meets the application's speed requirements. |

| Voltage Rating | Nominal voltage for optimal performance. | Impacts compatibility with power supply. |

| Controller Compatibility | Whether the motor can be easily interfaced with a controller. | Essential for efficient motor operation and control. |

| Size and Weight | Physical dimensions and weight of the motor. | Important for space-constrained applications. |

| Cooling Method | How the motor dissipates heat during operation. | Affects motor longevity and performance stability. |

| Efficiency | The ratio of output power to input power. | Directly influences energy consumption and heat generation. |

| Life Expectancy | Estimated operational lifespan under normal conditions. | Critical for planning maintenance schedules and costs. |

| Operating Temperature | Temperature range in which the motor operates safely. | Ensures reliable performance in various environments. |

| Noise Level | Sound emitted during operation. | Important for applications requiring quiet operation. |

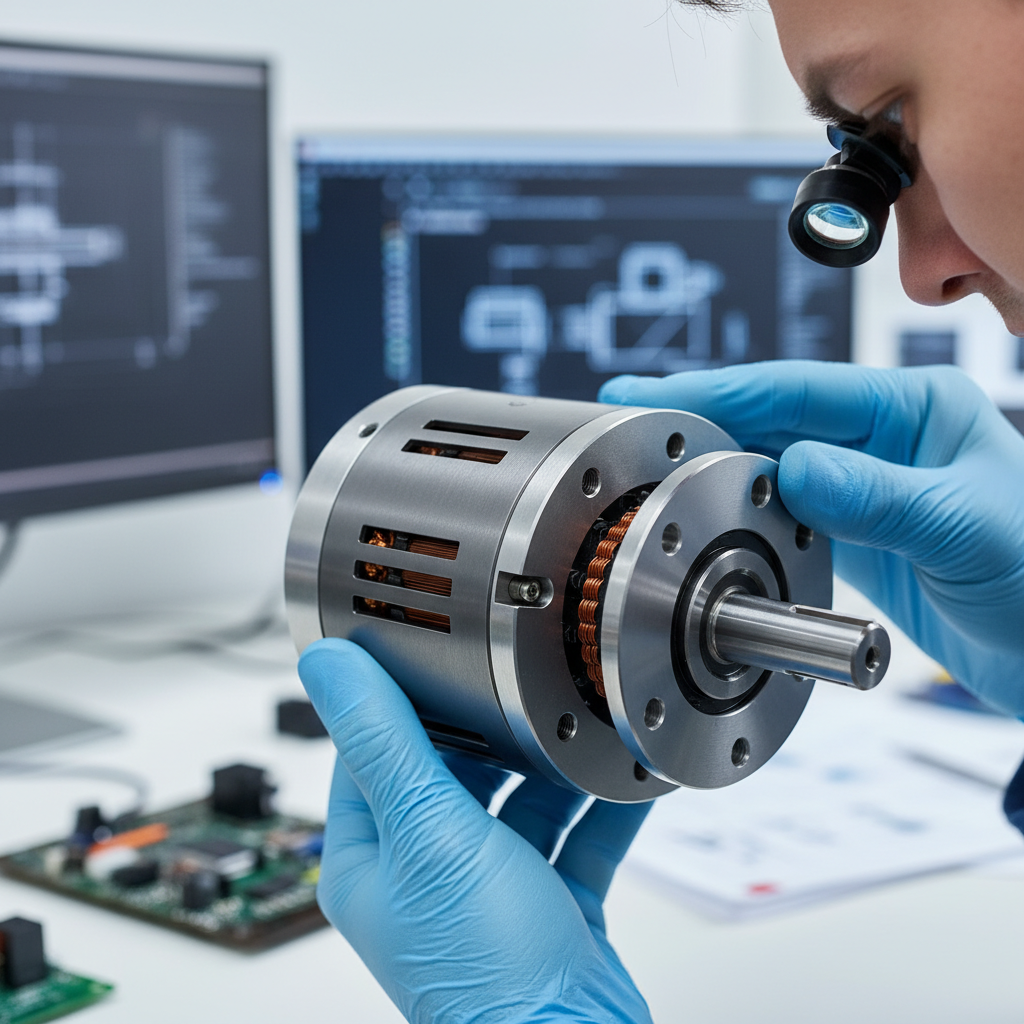

When selecting a high torque Brushless DC (BLDC) motor for your project, understanding load, speed, and torque specifications is critical. According to a recent industry report by MarketsandMarkets, the global BLDC motor market is expected to grow to $27.96 billion by 2025, highlighting the rising demand and the importance of precise motor selection based on application requirements. The load on the motor dictates how much power it needs to generate; for example, applications requiring consistent torque over varying loads may benefit from motors with a high torque-to-weight ratio.

Speed is another decisive factor. High torque BLDC motors are often designed for high-performance applications, which can range from robotics to electric vehicles. An industry study published by Research and Markets states that motors with a torque rating of 1.5 Nm to 3 Nm are ideal for most industrial applications where speed control and responsiveness are essential. These specifications help determine the appropriate motor size and configuration, ensuring optimal performance under specific operational conditions. By carefully analyzing these factors, engineers can tailor their motor choices to suit particular requirements, thereby enhancing the efficiency and reliability of their projects.

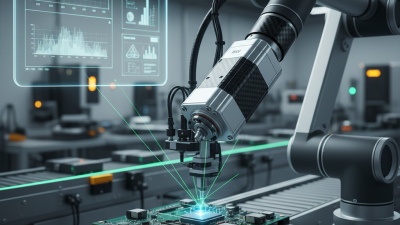

When selecting a high torque BLDC motor for your project, understanding the efficiency captured in the motor performance curves is crucial. These curves provide a graphical representation of various operational parameters, including torque, speed, and efficiency across different loads. By analyzing these curves, you can determine how well the motor performs under specific conditions, ensuring that it meets the demands of your application.

Moreover, the efficiency of a BLDC motor is often influenced by its design and construction. Performance curves allow you to compare not only the peak efficiency but also the operational range of the motor. This information is invaluable as it helps in anticipating performance variations with changing loads, which is especially important in applications where consistent torque delivery is required. Evaluating these curves helps ensure that you select a motor that does not only perform well at peak output but also maintains efficiency across its operational spectrum. Thus, a deep dive into the performance curves of potential motors will lead you to a more informed and effective choice for your project.

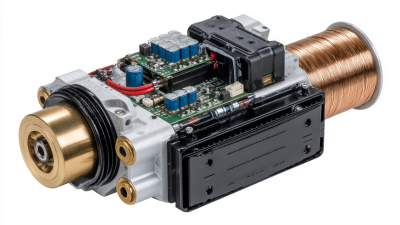

When selecting a high torque BLDC motor for your project, the choice of materials used in the motor's construction is crucial for ensuring durability and performance. According to a report by the International Electrotechnical Commission (IEC), over 30% of motor failures can be traced back to inadequate material selection, emphasizing the importance of using high-quality components. For instance, rotors made from high-grade silicon steel not only enhance magnetic efficiency but also significantly reduce eddy current losses, thereby increasing the overall lifespan of the motor.

Additionally, insulation materials play a vital role in maintaining motor integrity under various operating conditions. A study by the Institute of Electrical and Electronics Engineers (IEEE) found that motors utilizing advanced insulation systems can withstand temperatures up to 180°C while enduring harsher environmental factors. Opting for components such as epoxy resin or high-performance polymers can provide not only thermal resistance but also moisture protection, ensuring that your BLDC motor continues to perform optimally even in adverse conditions. As project requirements become more demanding, investing in the right materials is essential for both reliability and efficiency.

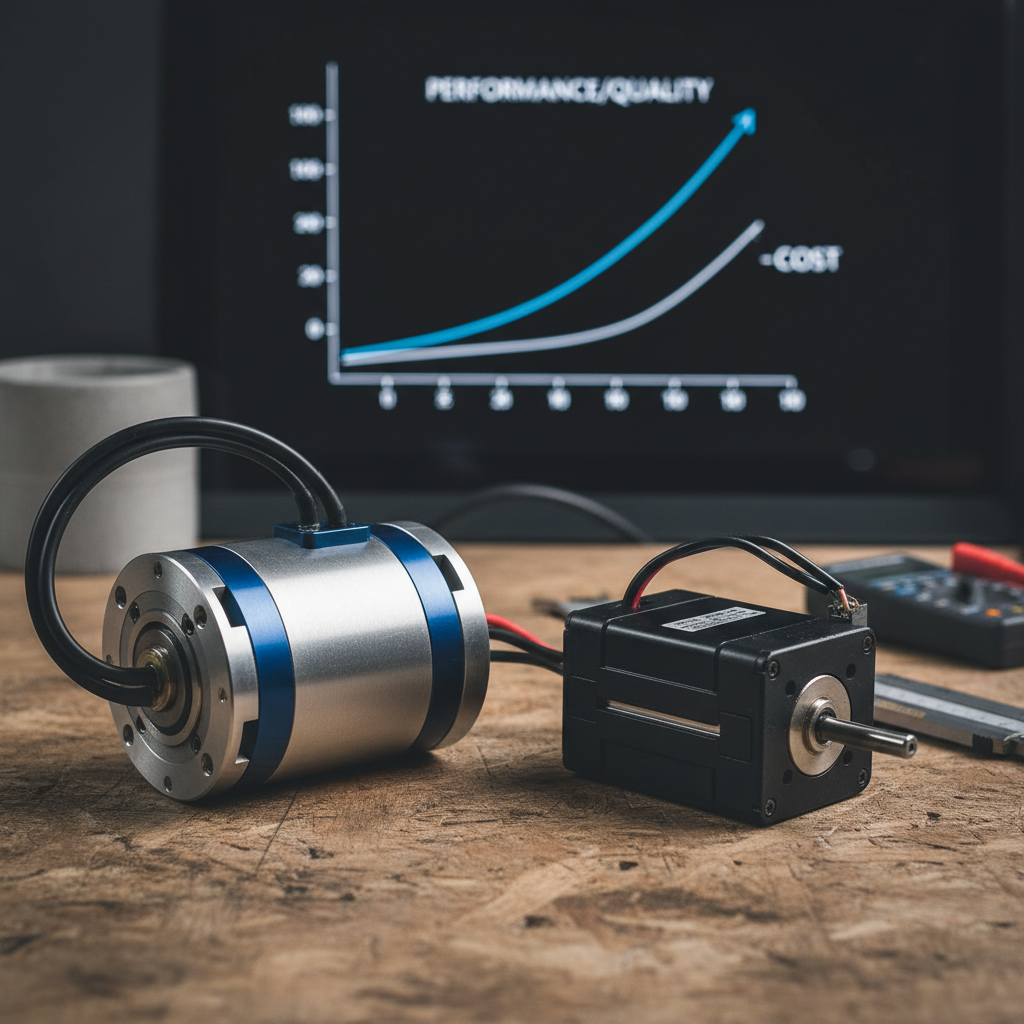

When selecting a high torque Brushless DC (BLDC) motor for your project, it's crucial to find the right balance between cost and quality. High-performance motors often come with a higher price tag, but the long-term benefits can outweigh the initial investment. While it might be tempting to opt for a lower-cost option, doing so may lead to compromised performance and reliability, ultimately increasing maintenance costs and downtimes. By focusing on quality, you ensure that the motor operates efficiently, delivering the required torque consistently and reducing the need for frequent replacements.

Additionally, understanding your project's specific requirements is essential for making informed choices. Assess the application environment, load conditions, and desired efficiency. Sometimes, investing in a more expensive motor can enhance overall performance and durability, translating to lower operational costs over time. Before finalizing your decision, conduct a thorough cost-benefit analysis that considers not only the upfront costs but also the long-term implications of choosing lower-quality options. This strategic approach will help you achieve a reliable solution that meets your performance expectations while keeping your budget in check.