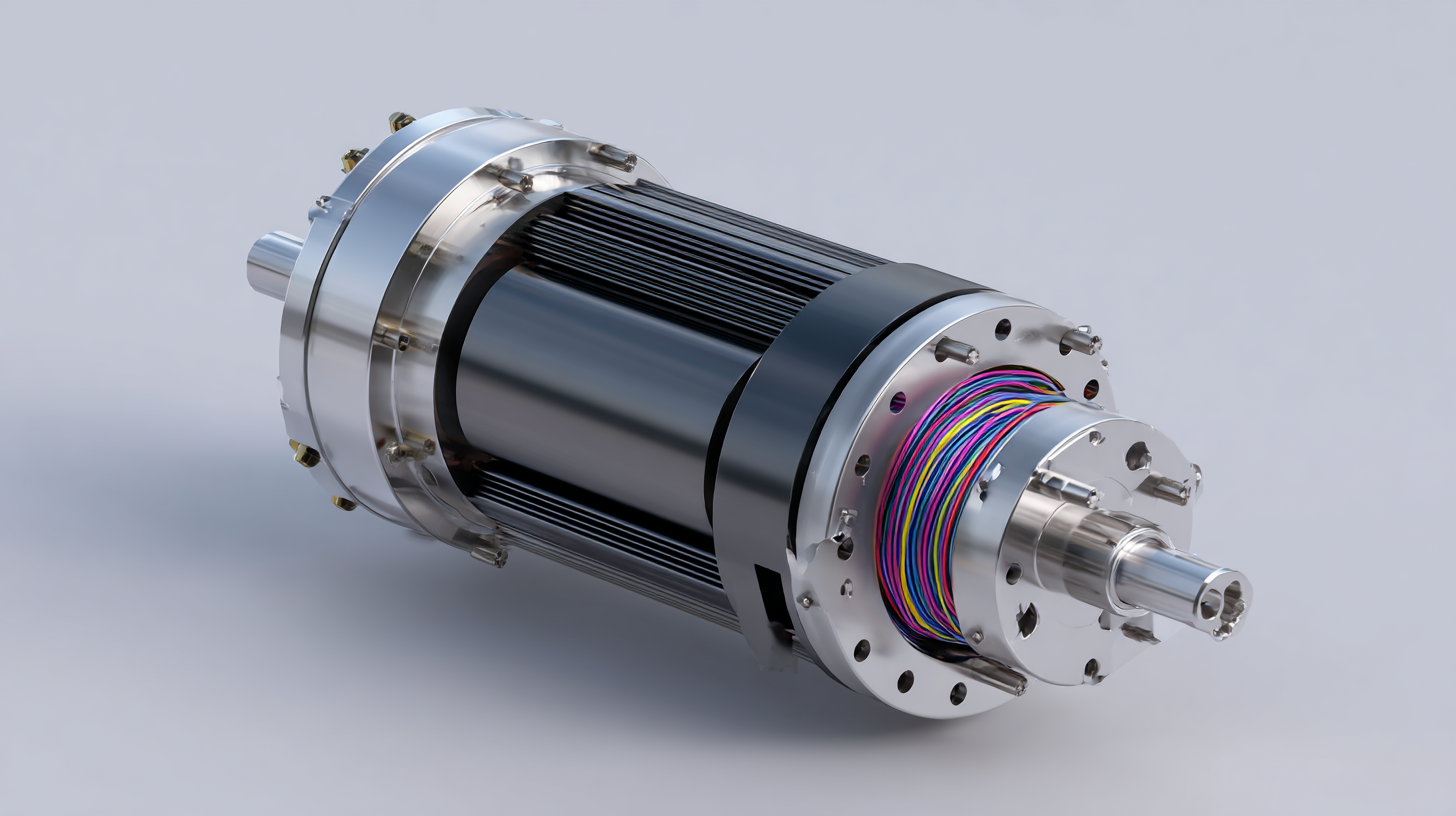

In the rapidly advancing world of technology, the demand for efficient and compact solutions is ever-growing. Among the innovations driving this change is the Frameless BLDC Motor, which stands out for its unique design and numerous advantages. Unlike traditional motors, frameless BLDC motors eliminate the need for an outer housing, allowing for a lighter and more versatile configuration that can seamlessly integrate into a variety of applications. This key feature not only reduces weight but also enhances performance by enabling better heat dissipation and improving torque efficiency. As we delve deeper into the implications of frameless technology, it becomes clear that these motors are not merely an alternative; they are essential for modern engineering challenges across industries such as robotics, medical devices, and aerospace. This article will explore the transformative benefits of frameless BLDC motors, offering valuable insights and tips for harnessing their potential in contemporary applications.

The rise of frameless brushless DC (BLDC) motors in robotics is revolutionizing efficiency and design flexibility. As robotic applications demand higher precision and lighter components, frameless BLDC motors are becoming essential due to their compact design and enhanced performance characteristics. According to recent market research, the frameless BLDC motors market is expected to grow significantly, driven by the need for innovative solutions in automation and robotics. These motors provide an optimal power-to-weight ratio, making them ideal for mobile and agile robotic systems.

The integration of advanced manufacturing techniques, such as AI-assisted winding technologies, is further enhancing the capabilities of these motors. By utilizing flexible printed circuits, manufacturers can produce high-power density micromotor windings, leading to improved motor performance. This aligns perfectly with the needs of the robotics industry, where adaptability and performance are key. The modular nature of contemporary drive systems allows for seamless integration with various robotic architectures, streamlining design processes and reducing time to market. As industries continue to explore the potential of frameless motors, we are likely to see even more innovative applications that challenge the conventions of design and motion control.

| Application | Efficiency (%) | Design Flexibility (1-10) | Size (mm) | Weight (grams) |

|---|---|---|---|---|

| Robotics Arm | 90 | 8 | 50 | 150 |

| Drone Propulsion | 85 | 9 | 30 | 50 |

| Automated Guided Vehicle | 88 | 7 | 100 | 200 |

| Medical Robots | 92 | 9 | 40 | 120 |

| Industrial Automation | 87 | 6 | 70 | 180 |

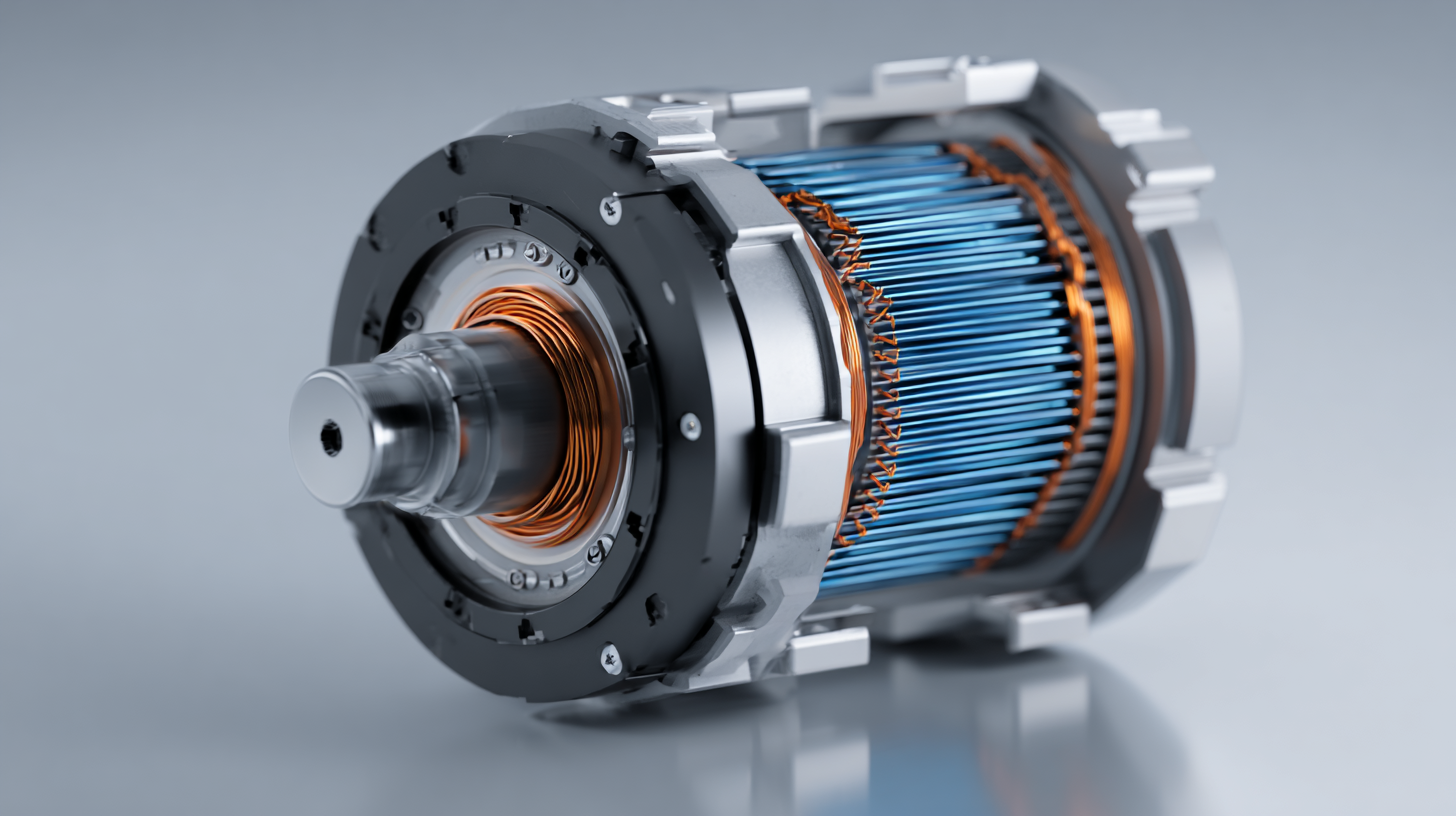

Frameless Brushless DC (BLDC) motors are rapidly gaining traction in modern applications, particularly due to their compact design and exceptional performance metrics. Unlike traditional motor designs, which typically consist of a stator and rotor assembly, frameless BLDC motors integrate more seamlessly within systems, allowing for higher torque density and reduced system weight. This innovative design is particularly advantageous in robotics and automation, where space and efficiency are critical.

The shift towards higher-torque-density motors with integrated drive electronics marks a significant departure from conventional BLDC motors that rely on separate drives. This evolution not only simplifies the overall architecture of motion control systems but also enhances reliability by minimizing the number of discrete components. As industries increasingly embrace these advancements, frameless BLDC motors stand at the forefront of transforming design paradigms and performance capabilities, setting a new standard for efficiency and innovation in electric motor technologies.

Frameless BLDC (Brushless Direct Current) motors are revolutionizing the automotive industry with their compact design and high efficiency. Unlike traditional motor designs, frameless motors eliminate the bulky outer frame, allowing for greater flexibility in installation and integration within various vehicle components. This space-saving capability is particularly beneficial in electric vehicles (EVs), where every inch of space contributes to overall vehicle performance and range.

Key applications of frameless BLDC motors in the automotive sector include advanced driver assistance systems (ADAS), electric power steering, and traction systems. In ADAS, these motors provide precise control and responsiveness, enhancing safety features such as adaptive cruise control and lane-keeping assistance. For electric power steering, the lightweight nature of frameless motors helps optimize energy consumption, contributing to improved battery life in EVs. Additionally, their use in traction systems allows for swift acceleration and enhanced vehicle handling, crucial for performance-oriented models. Overall, the integration of frameless BLDC motors is paving the way for more efficient, responsive, and innovative automotive technologies.

Frameless Brushless DC (BLDC) motors are rapidly becoming essential components in various modern applications, largely due to their exceptional energy efficiency. By eliminating the traditional housing found in conventional motors, these frameless designs minimize weight and size while maximizing performance. This compactness enables their integration into sophisticated systems such as robotics, automotive technology, and renewable energy solutions, where energy conservation is paramount. The efficient operation of frameless BLDC motors directly contributes to reduced energy consumption, aligning with global sustainability goals.

Frameless Brushless DC (BLDC) motors are rapidly becoming essential components in various modern applications, largely due to their exceptional energy efficiency. By eliminating the traditional housing found in conventional motors, these frameless designs minimize weight and size while maximizing performance. This compactness enables their integration into sophisticated systems such as robotics, automotive technology, and renewable energy solutions, where energy conservation is paramount. The efficient operation of frameless BLDC motors directly contributes to reduced energy consumption, aligning with global sustainability goals.

Moreover, the use of frameless BLDC motors supports sustainable practices by decreasing overall carbon footprints. Their higher efficiency not only reduces operational costs but also leads to lower energy demands over time. In applications such as electric vehicles and energy-efficient appliances, these motors can significantly enhance the energy profiles, promoting a shift towards greener technologies. As industries move to embrace eco-friendly innovations, the role of energy-efficient motors becomes even more critical, solidifying frameless BLDC motors as pivotal in driving sustainable development across various sectors.

The frameless brushless DC (BLDC) motors market is poised for significant growth, driven by innovations that enhance precision and efficiency in various applications. As industries increasingly adopt automation technologies, the demand for compact and high-performance motion solutions rises. The adaptability of frameless BLDC motors makes them ideal for modern designs, facilitating advancements in robotics, medical devices, and consumer electronics. This trend is underscored by the rapid expansion of related markets, such as robotics, which are projected to revolutionize sectors focused on human health and well-being.

Looking forward, market projections indicate robust growth for frameless BLDC motors in the coming years. Analysts forecast that as the global high torque stepper motor market is set to surpass USD 1.94 billion by 2034, frameless BLDC motors will play a critical role in achieving advanced automation capabilities. The increasing emphasis on compactness and efficiency will further drive demand, ensuring that frameless motors remain at the forefront of technological innovation as industries strive to enhance performance and productivity across diverse applications.