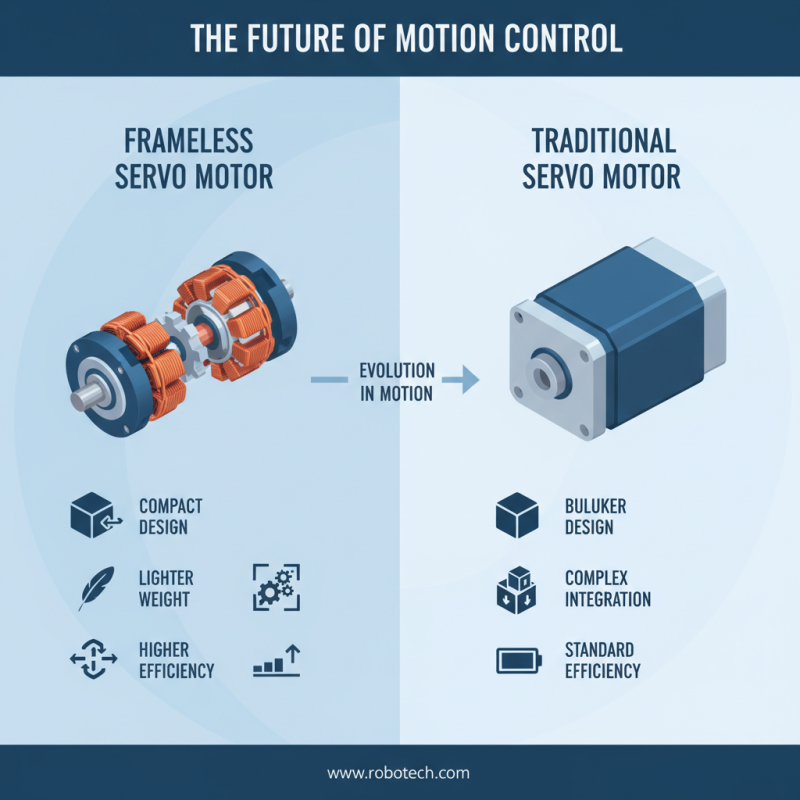

The Frameless Servo Motor is a unique type of motor without a traditional casing. This design allows for greater flexibility in various applications. Frameless servo motors are commonly used in robotics, CNC machines, and medical devices.

These motors stand out due to their compact and lightweight design. They offer high precision and efficiency compared to standard servo motors. By eliminating the external housing, frameless servo motors achieve improved torque density. This aspect is crucial for systems requiring high-speed and accurate positioning.

However, the frameless design also presents challenges. Installing these motors can be complex. Without a frame, proper alignment during integration is vital. Any misalignment can lead to reduced performance. Understanding the intricacies of the frameless servo motor is essential for optimizing its capabilities. Each application may reveal unexpected hurdles that require careful consideration.

Frameless servo motors are a unique class of motors designed for precision applications. Unlike traditional servo motors, they lack an outer housing. This allows for easier integration into machines and robotics. They are specifically tailored for high-performance tasks requiring accuracy and speed, such as in CNC machines and robotic arms. According to industry reports, the frameless servo motor market is expected to grow significantly, with an estimated CAGR of over 8% by 2027.

These motors provide several advantages. They typically have a shorter response time compared to their framed counterparts. This makes them ideal for applications that require rapid direction changes. Data shows that they can achieve precision within micrometers, making them invaluable in fields like biomedical technology and aerospace. However, the lack of a frame can also mean increased vulnerability. Without a protective casing, careful handling during installation is crucial.

Integration may require additional components to optimize performance. This adds complexity to the design process. Engineers must consider how to align these motors precisely within their systems. Any misalignment can lead to performance issues. Though frameless servo motors have many benefits, there are challenges that require careful planning and execution.

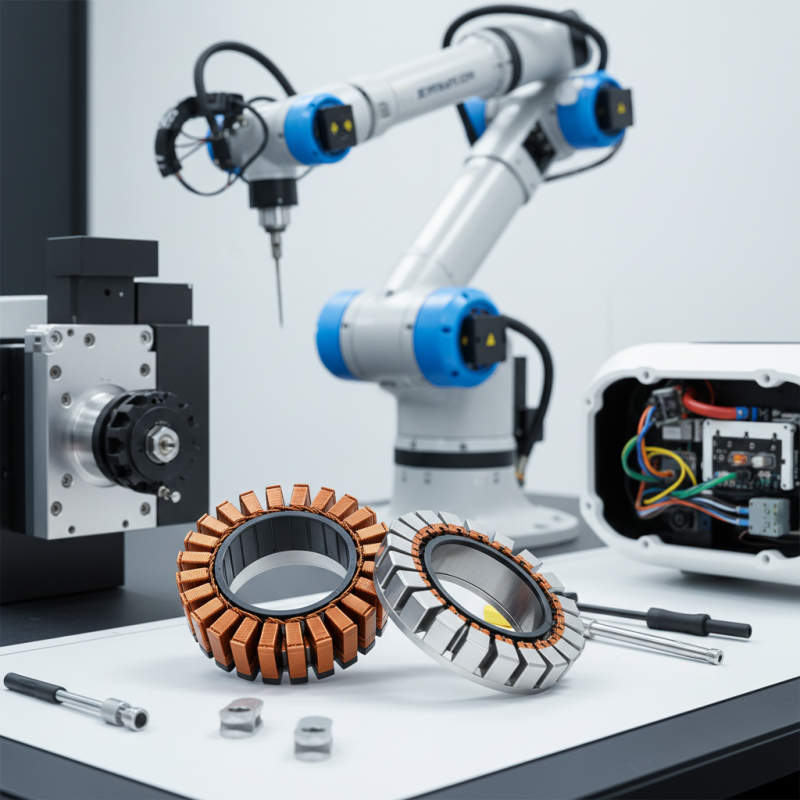

Frameless servo motors are unique in their design. Unlike traditional motors, they lack a casing. This allows for greater flexibility in integration. The components can be embedded directly into machines, saving space and weight. However, this design requires precise alignment during installation, which can be challenging.

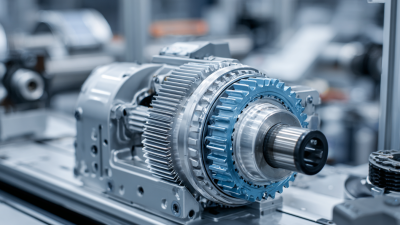

Key components of frameless servo motors include the rotor and stator. The rotor spins, creating motion, while the stator remains stationary. Together, they enable smooth and efficient operation. Additionally, feedback sensors are integral. These sensors provide real-time data, enhancing accuracy. However, if miscalibrated, they can lead to performance issues.

The overall construction uses high-quality materials. These ensure durability and reliability in various environments. Yet, if not maintained properly, wear and tear can significantly affect performance. This highlights the need for regular check-ups. Designing with these components in mind is crucial. Balancing efficiency and robustness can be quite a task.

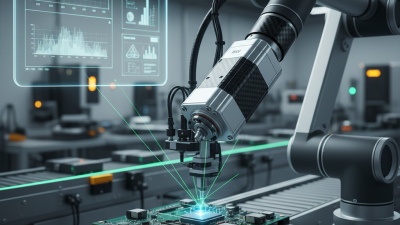

Frameless servo motors are unique developments in motion control. They differ from traditional servo motors by lacking an outer casing. This design allows for easier integration into various machinery. The core of a frameless servo motor consists of a rotor and a stator. When electrical signals are applied, the rotor spins, creating motion. This is essential in robotics and automation.

The operation is grounded in electromagnetic principles. When current flows through the coils in the stator, it generates a magnetic field. This field interacts with magnets on the rotor, leading to motion. The absence of a housing reduces size and weight, making it easier to fit into tight spaces. However, this can sometimes lead to overheating, as the motor lacks sufficient casing for heat dissipation.

**Tip**: Ensure proper cooling mechanisms are in place. This will enhance motor performance and lifespan.

Maintenance is crucial, as the lack of an outer casing can expose internal components to dust and debris. Be vigilant about cleaning.

**Tip**: Regularly inspect the motor for wear. Doing so can prevent failure in critical applications.

This chart illustrates the performance metrics of frameless servo motors, including speed in RPM, torque in Nm, efficiency in percentage, and response time in milliseconds. These metrics highlight the capabilities and operational efficiency of frameless servo motors in various applications.

Frameless servo motors are becoming increasingly popular in robotics and automation. Their compact design allows for seamless integration with robotic structures. Unlike traditional motors, frameless servo motors lack an outer casing. This characteristic enables precision control in tight spaces. Many industries benefit from using these motors, especially in applications that require high torque and high speed.

In collaborative robots (cobots), frameless servo motors play a vital role. They support smooth and responsive movements, which is essential in human-robot interactions. According to industry reports, the use of servomotors in robotics is projected to grow significantly, with a CAGR of 8.1% from 2021 to 2026. This growth highlights the increasing reliance on advanced automation solutions. However, integrating these motors can present challenges, such as compatibility with existing systems.

Automation in manufacturing lines has also seen a surge in frameless servo motor applications. Their ability to enhance speed and accuracy in robotic arms is noteworthy. A report indicated that 60% of manufacturers are considering servo technology to improve efficiency. However, the learning curve for implementing these motors can be steep for some teams. Finding the right balance between innovation and practicality remains a concern.

| Specification | Value | Application Area |

|---|---|---|

| Rated Torque | 0.5 - 20 Nm | Robotics |

| Rated Speed | 1000 - 6000 RPM | CNC Machines |

| Power Supply Voltage | 24 - 480 V | Industrial Automation |

| Communication Interface | CANopen, EtherCAT | Mechatronics |

| Feedback Mechanism | Incremental Encoder | Automated Guided Vehicles |

Frameless servo motors are becoming popular in various industries. They differ significantly from traditional servo motors. One major advantage is their compact design. Without an outer housing, frameless motors are lighter. This allows for better integration into tight spaces. They enhance the system's overall efficiency.

In applications requiring high torque or precise movement, frameless motors excel. Their direct attachment to the load often leads to improved performance. They eliminate mechanical backlash, which is commonly found in traditional motors. This results in smoother operation and accurate positioning. However, integrating a frameless motor can be more complex. It requires careful consideration of mounting and alignment.

**Tip:** When evaluating a motor system, consider the specific application. Frameless motors might be ideal for robotics and automation. Still, ensure that you have the expertise for proper installation.

Another benefit is the customization potential. Frameless motors can be designed to meet specific project needs. However, this often means higher upfront costs and longer lead times. Rethink your budget carefully. Balancing initial costs with long-term benefits is essential.

**Tip:** Always consult with engineers during the selection process. Their insights can help optimize the motor choice for your unique requirements.