The importance of Frameless Torque Motors in industrial applications cannot be overstated. These advanced motors provide unparalleled precision and efficiency, making them vital in sectors such as robotics, aerospace, and manufacturing. According to a recent market report by the International Electromechanical Association, the global demand for Frameless Torque Motors is expected to grow by 20% annually through 2025. Industry expert Dr. Emily Smith stated, “Frameless Torque Motors enable higher performance while minimizing footprint, which is critical in today's compact designs.”

Using these motors effectively requires understanding several key factors. For instance, heat dissipation is crucial; inadequate cooling can lead to performance issues. Users often face challenges in matching motor specifications to their applications. This mismatch can hinder optimal performance and reduce lifespan. Recognizing these potential pitfalls is essential for maximizing the benefits of Frameless Torque Motors.

Ultimately, mastering the use of Frameless Torque Motors involves both understanding their capabilities and addressing inherent limitations. As technology continues to evolve, staying informed is necessary for leveraging the full potential of this powerful drive solution. Engaging with experts and industry reports can provide useful insights into best practices and common mistakes to avoid.

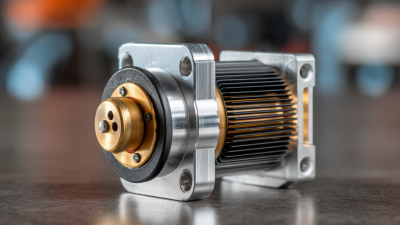

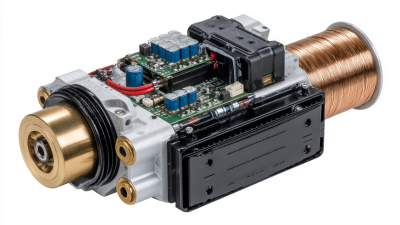

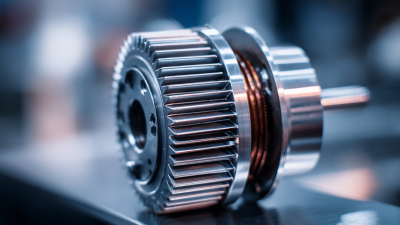

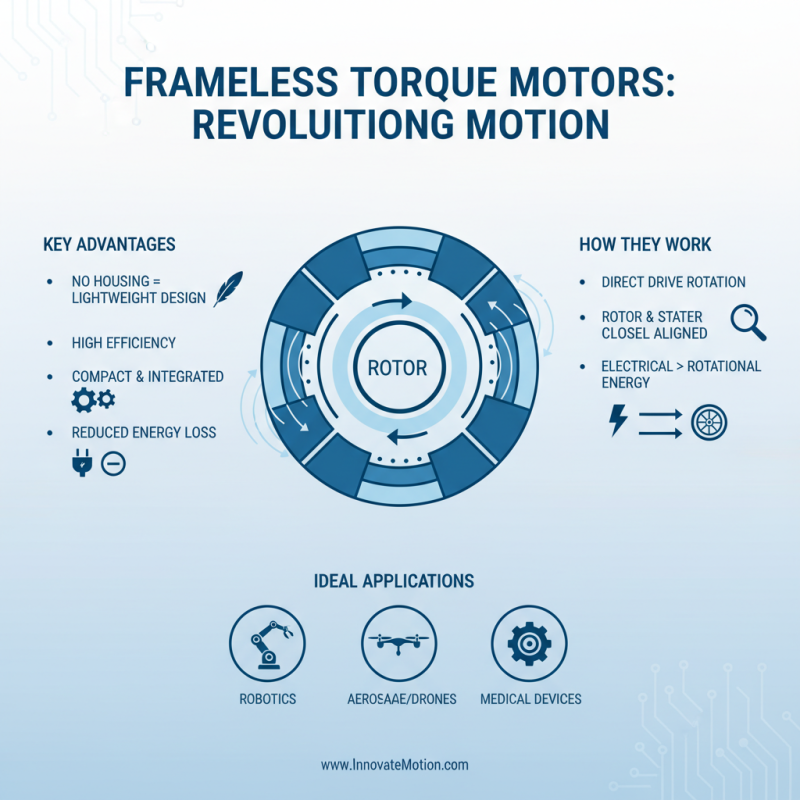

Frameless torque motors are innovative devices that transform electrical energy into rotational motion. Unlike traditional motors, they have no housing. This allows for a lightweight design, making them ideal for various applications. Their construction includes a rotor and stator, aligned closely to enhance efficiency. The close coupling between parts reduces energy loss and increases performance.

Tips for optimal performance include ensuring proper alignment during installation. Misalignment can lead to inefficiencies and increased wear. Regular maintenance checks are crucial. They help identify issues early, before they escalate. Additionally, pay attention to the motor’s operating temperature. Overheating can diminish performance and shorten lifespan.

Understanding these components leads to better usage. These motors require precise control for optimal output. Always consult technical documents for specifications. This can prevent mistakes that compromise efficiency. Reflecting on past experiences with similar devices can reveal important lessons for improvement.

Frameless torque motors are increasingly popular in industrial applications. These motors offer impressive torque density and compact design. They excel in precision tasks, making them ideal for robotics and automation. To fully benefit from them, understanding key performance metrics is essential.

Key performance metrics include torque output, efficiency, and thermal management. Torque output should match the application’s requirements. If it falls short, the system may stall. Efficiency impacts energy consumption; lower efficiency can lead to overheating. Thus, it’s vital to monitor temperature levels during operation.

Here are some tips for optimal usage. Ensure proper alignment to minimize wear. Regularly check electrical connections for signs of corrosion. Vibration can indicate imbalance; address it early. Don’t forget to evaluate load conditions periodically. Adjust settings based on real-time performance data. Small tweaks can enhance overall functionality. Maintaining awareness helps achieve better results.

When using a frameless torque motor, paying attention to operating conditions is crucial. Temperature plays a significant role in performance and longevity. High temperatures can lead to overheating, which may damage internal components. Keeping the motor at an optimal temperature ensures smoother operation and greater efficiency.

Load conditions also impact motor health. Overloading can strain the system, resulting in reduced lifespan. It is essential to assess load requirements carefully. Regular checks can help maintain stability and reveal potential issues early. These small adjustments may prevent costly breakdowns.

Ignoring these factors might seem harmless initially. However, even minor miscalculations can lead to significant problems over time. Learn to monitor both temperature and load. Doing so can enhance performance and prolong the motor's lifespan. Remain vigilant about these details; they can save headaches later on.

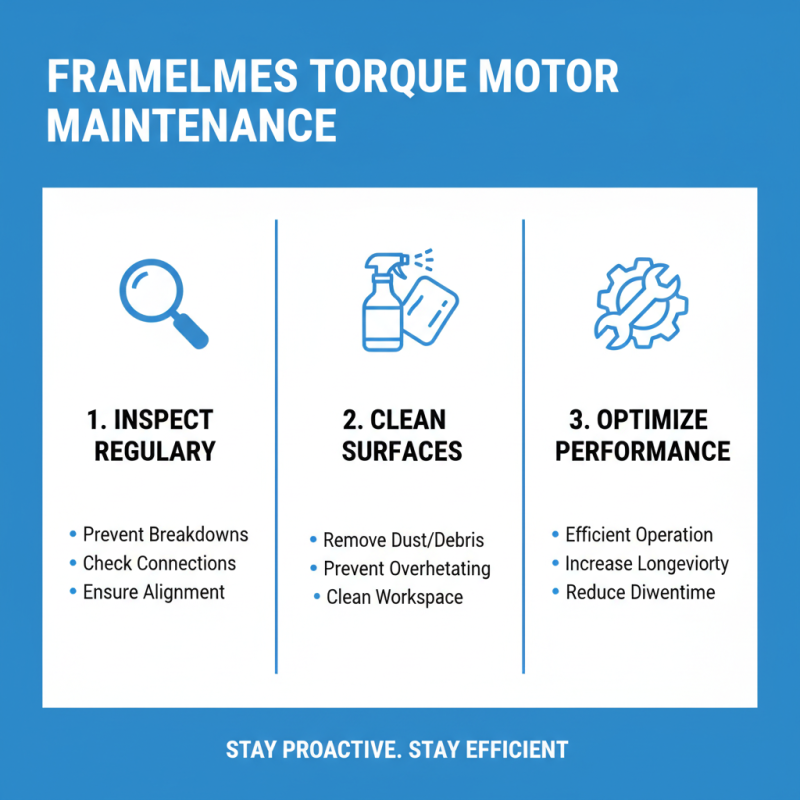

Maintaining frameless torque motors is essential for efficient operation. Regular inspections prevent unexpected breakdowns. Check connections, clean surfaces, and ensure proper alignment. Dust and debris can cause overheating. A clean workspace is crucial for longevity.

Lubrication is key. Use the right type of grease, but don't overdo it. Too much can attract dirt. A simple visual check can save you from bigger issues down the line. Dirt can wear out components quickly, decreasing performance.

Pay attention to temperature levels. Running hot can shorten the motor's lifespan. Install temperature sensors for real-time monitoring. Be mindful of load conditions; excessive loads can strain the motor. If you notice unusual sounds or vibrations, investigate immediately. These are signs that maintenance is needed.

In recent years, torque motors have undergone significant advancements, particularly in their applications across various industries. According to a report by MarketsandMarkets, the global torque motor market is projected to reach $8.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.6%. This growth is driven by increasing automation and the demand for precision engineering in manufacturing.

Emerging trends highlight the integration of torque motors with smart technology. Internet of Things (IoT) capabilities allow for real-time monitoring and control, greatly enhancing operational efficiency. However, the challenge lies in ensuring compatibility with existing systems. Many companies face integration issues due to legacy equipment, which can hinder performance improvements.

Another notable trend is the shift towards eco-friendly designs. Manufacturers are now focusing on reducing energy consumption. According to a study by the International Energy Agency, improving motor efficiency could cut global energy demand by 10%. Yet, achieving this requires significant R&D investment. The pursuit of innovation often leads to inconsistent results, reminding us that while technology evolves, overcoming legacy obstacles remains a critical area for reflection.

| Dimension | Specification | Optimal Usage Tips | Emerging Trends |

|---|---|---|---|

| Torque Output | 1.5 - 20 Nm | Ensure proper load alignment | Integration with IoT systems |

| Speed Range | 100 - 5000 RPM | Monitor temperature for longevity | Developments in wireless control |

| Efficiency | 85% - 95% | Use high-quality bearings | Advancements in cooling technologies |

| Size | 40 mm - 150 mm | Compact design for space-saving | Flexible mounting options |

| Weight | 0.5 - 5 kg | Optimize weight distribution | Lightweight materials |