In the evolving landscape of automation and robotics, the choice of motor technology is crucial. Frameless torque motors stand out as a preferred solution for precision applications. According to a recent industry report, frameless motors boast efficiency rates exceeding 90%, outperforming traditional designs. This efficiency translates into reduced energy consumption and lower operating costs.

Frameless torque motors are compact and versatile. Their design allows for direct integration into systems, saving valuable space. This aspect is increasingly important in advanced manufacturing setups where every inch counts. Moreover, they offer high torque density, enabling faster response times and improved performance. Data indicates that applications using these motors experience up to 30% higher throughput.

However, it is essential to consider the limitations. The initial costs may be higher than other motor types. This could be a barrier for some businesses. While frameless torque motors present clear advantages, decision-makers must weigh performance benefits against upfront investment. Ultimately, careful consideration can lead to optimized solutions in various sectors, from medical devices to aerospace.

Frameless torque motors are gaining traction in industrial applications due to their numerous advantages. These motors provide high torque density, enabling compact designs. According to a recent industry report, frameless motors can deliver torque outputs up to 20 Nm per square centimeter. This means more power in less space, which is crucial for manufacturers looking to optimize machinery designs.

Another benefit is their direct integration into systems. By eliminating the need for a gearbox, these motors reduce the overall mechanical complexity. They can directly drive loads, leading to improved efficiency. Reports suggest that using frameless motors can improve system efficiency by 30%. This reduction in components also minimizes wear and tear. However, some engineers may face challenges in heat management since frameless motors often require distinct cooling solutions.

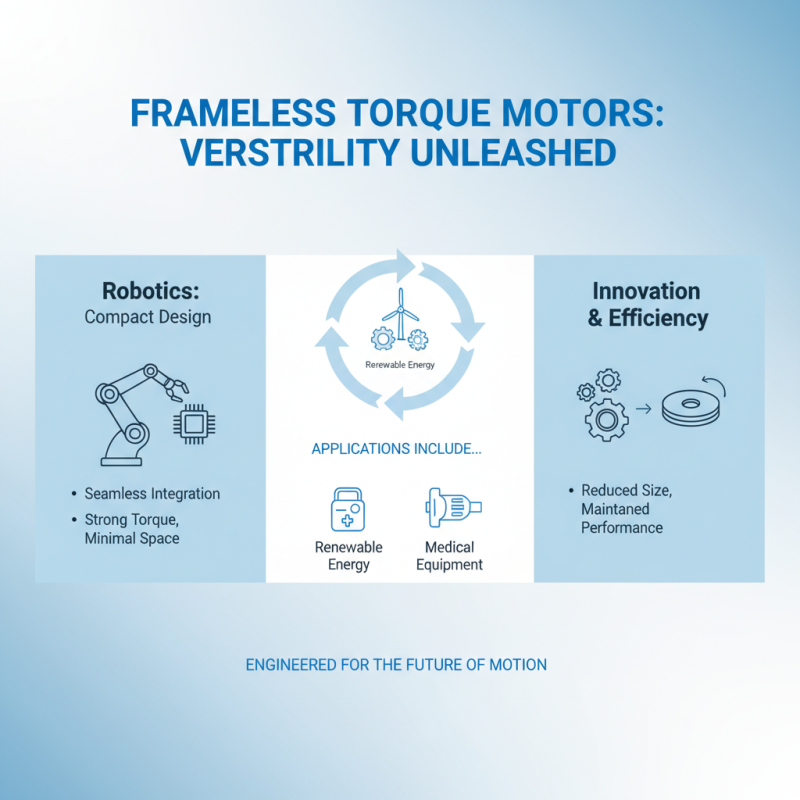

Additionally, the adaptability of frameless torque motors allows them to cater to various applications, from robotics to aerospace. Their design flexibility can lead to custom solutions. Yet, not every application may benefit from this technology. Integration costs could be high, especially in older systems. Companies must consider whether the investment aligns with their operational goals. Moving forward, the decision to use frameless torque motors should be carefully weighed against these factors.

Frameless torque motors are gaining traction in various applications. They differ significantly from conventional motors. For example, frameless designs allow for greater flexibility in installation. This can lead to reduced overall system weight, important in aerospace and medical devices.

One key advantage is their efficiency. According to industry reports, frameless torque motors offer up to 90% efficiency, compared to 80% for conventional motors. That’s a significant increase. These motors also provide superior torque density. When space is at a premium, frameless designs excel. They can fit into tighter spaces while delivering high performance.

**Tip:** Consider your application’s space constraints when choosing between motor types. Ensure that you evaluate the mounting options thoroughly.

However, frameless motors can be more complex. Controllers may require specific tuning for optimal performance. This could result in additional costs and learning curves for engineers. Understand this trade-off before making a decision.

**Tip:** Consult with experts during the selection process. Their insights can guide you in addressing design complexities.

In conclusion, frameless torque motors present notable advantages. Yet, they may also require thoughtful planning to integrate seamlessly into your systems.

| Feature | Frameless Torque Motors | Conventional Motors |

|---|---|---|

| Size and Weight | Compact and lightweight design | Bulkier and heavier |

| Torque Density | High torque output in a small package | Lower torque output for size |

| Integration | Easily integrated into existing systems | Requires more space and complex installation |

| Heat Generation | Lower heat generation during operation | Higher heat generation requiring cooling systems |

| Cost | Higher initial investment | Lower initial purchase cost |

| Efficiency | Higher efficiency and performance | Generally lower efficiency |

| Application Flexibility | Highly adaptable to various applications | Limited flexibility in specific applications |

Frameless torque motors are gaining traction due to their unique specifications. When considering torque, these motors can deliver significantly higher outputs than traditional designs. Reports indicate that some frameless motors achieve torque densities exceeding 5 Nm/kg. This allows for compact designs without sacrificing performance.

Speed is another critical factor. Frameless torque motors often operate efficiently at high RPMs. They can reach speeds of over 6000 RPM in specific applications. This high-speed capability enables them to excel in precision tasks like robotics and CNC machinery. However, achieving such speeds can bring challenges in heat management and lifecycle.

Efficiency remains paramount. Many frameless motors achieve efficiency ratings of up to 90%. This reduces energy consumption and operational costs. Yet, some applications may struggle to maintain this efficiency under variable loads. Continuous monitoring and adjustments are necessary to avoid loss of performance. The data clearly shows that while frameless torque motors offer promising specifications, their implementation requires careful consideration.

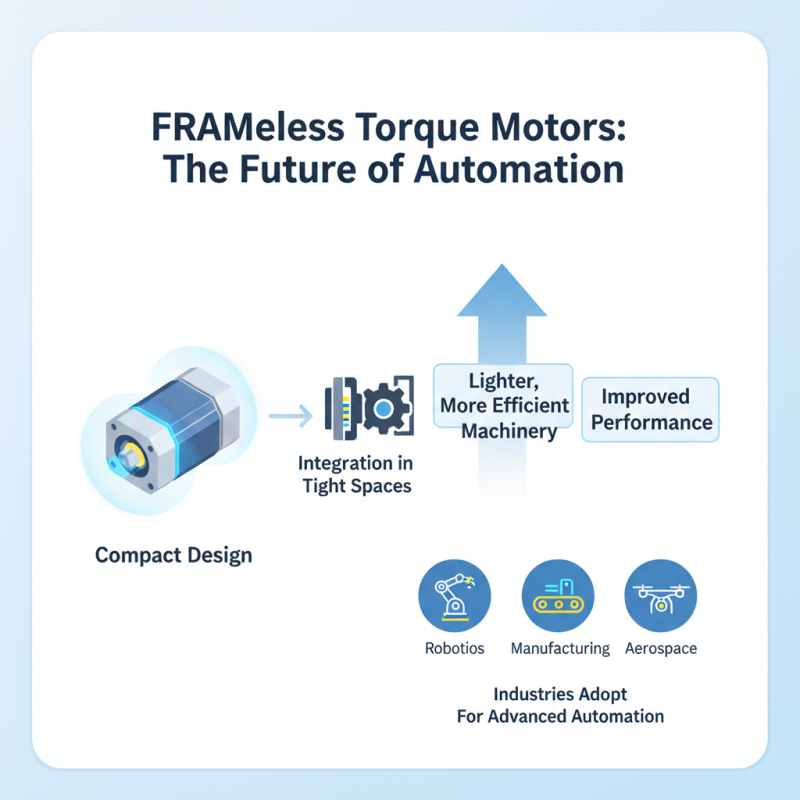

Frameless torque motors are gaining traction in the automation sector. Their compact design allows for integration in tight spaces. This trend is driven by the demand for lighter, more efficient machinery. Industries are turning to these motors for improved performance.

One significant aspect is the growing need for precise control. Frameless torque motors provide high torque and low inertia. This makes them suitable for robotics and CNC machines. With automation on the rise, companies seek reliable components. Yet, not all applications will benefit equally. It's essential to assess specific needs carefully.

Tips: Consider your application environment. Does it require high precision, or is speed more critical? Evaluate power requirements versus size constraints. This will guide your motor selection effectively. Be open to experimenting. Sometimes, the best solution isn't the most obvious. Embrace trial and error as part of the learning process.

Frameless torque motors have shown remarkable versatility across various applications. In robotics, these motors provide a compact design that integrates seamlessly into machines. The ability to create strong torque with minimal space allows for innovative designs and efficient movement. An example is an advanced robotic arm that performs delicate tasks. Engineers noted a significant reduction in size while maintaining performance.

In aerospace applications, frameless torque motors help in controlling critical systems. One case study illustrated their role in stabilizing UAVs. The motors enabled precise adjustments to the flight control surfaces, enhancing stability during flight. However, challenges arose in integrating these motors with existing hardware, requiring careful recalibration.

**Tip:** When considering frameless torque motors, focus on installation space and alignment. Misalignment can lead to performance issues. Also, pilot testing is crucial to gauge system compatibility before full implementation.

In manufacturing, frameless torque motors are used in conveyor systems. They improve efficiency by reducing energy consumption while maintaining speed. A case study showed notable energy savings during peak operations. Yet, some operators reported difficulties in workload management. Striking a balance between speed and precision can be tricky.

**Tip:** Always assess maintenance needs. Regular checks can prevent unexpected downtime. In high-demand environments, plan for potential delays in sourcing replacement parts.