In today's rapidly advancing technological landscape, the demand for efficient and reliable power solutions has never been greater, making the selection of the right Large Brushless Motors a critical factor for success across various applications. These high-performance motors stand out due to their ability to provide superior efficiency, reduced maintenance, and enhanced performance, making them ideal for industries ranging from robotics to electric vehicles. As you delve into the complexities of choosing the perfect large brushless motor for your specific needs, it's essential to understand the various types and specifications available in the market. This ultimate guide will walk you through everything you need to know, helping you navigate the intricacies of large brushless motors to ensure optimal selection and implementation for improved operational efficiency and long-term reliability.

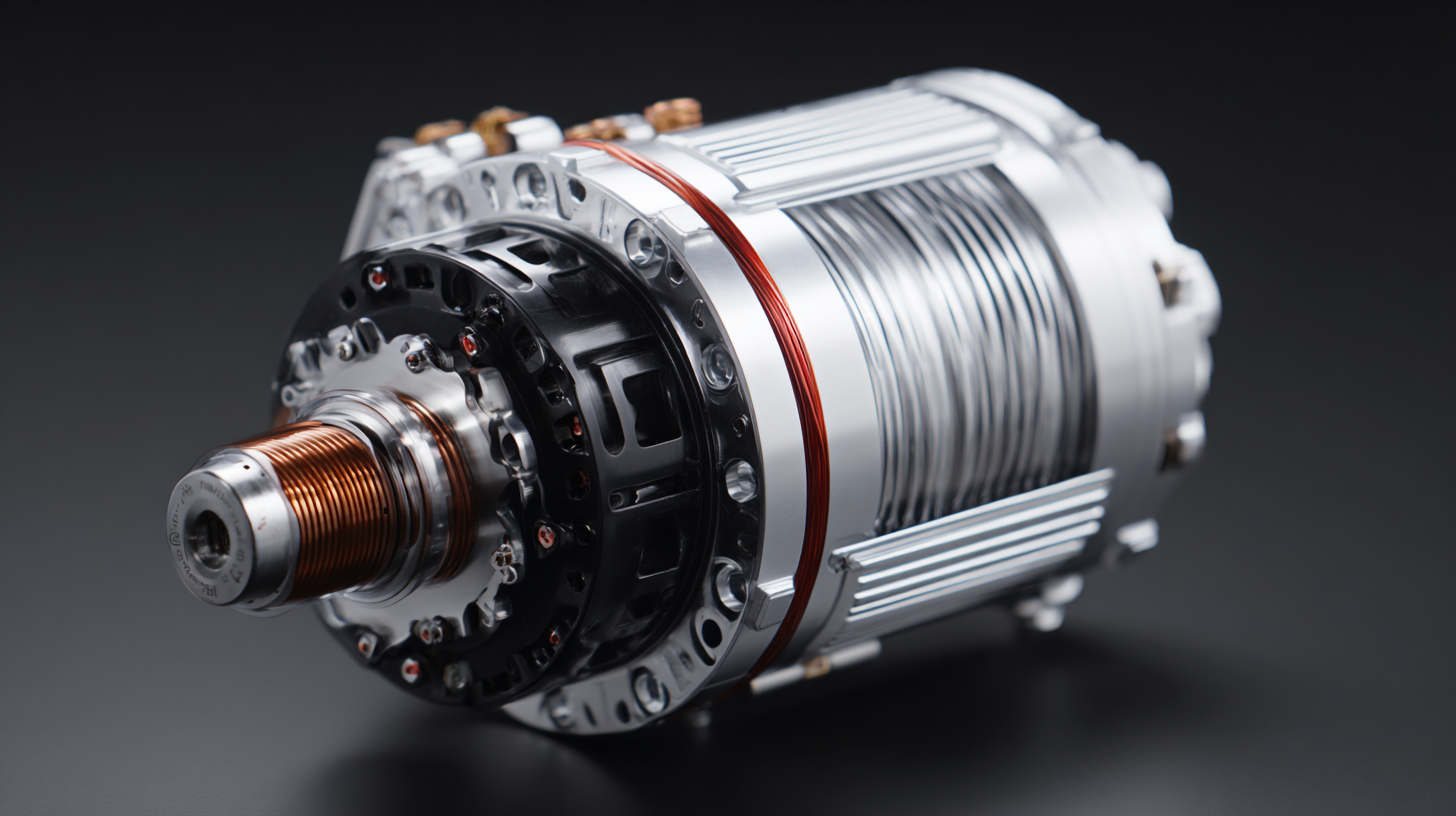

Large brushless motors are designed to offer superior performance and efficiency compared to their brushed counterparts. One of the key features of these motors is their construction, which eliminates brushes that typically wear out over time. This not only extends the motor's lifespan but also reduces maintenance costs, making them ideal for heavy-duty applications. Enhanced efficiency is another significant benefit, as large brushless motors can convert electrical energy to mechanical power with minimal losses, leading to lower operational costs and less heat generation.

Large brushless motors are designed to offer superior performance and efficiency compared to their brushed counterparts. One of the key features of these motors is their construction, which eliminates brushes that typically wear out over time. This not only extends the motor's lifespan but also reduces maintenance costs, making them ideal for heavy-duty applications. Enhanced efficiency is another significant benefit, as large brushless motors can convert electrical energy to mechanical power with minimal losses, leading to lower operational costs and less heat generation.

Moreover, large brushless motors provide better torque-to-weight ratios, allowing for greater power output without increasing size or weight. This characteristic is especially beneficial in applications requiring high performance in compact spaces, such as robotics, aerospace, and industrial machinery. Additionally, they offer smoother operation and quieter performance, which is essential in environments where minimal noise is critical. By understanding these key features and benefits, users can make informed decisions when selecting the right large brushless motors for their specific needs, ultimately enhancing efficiency and productivity in their operations.

When selecting large brushless motors, identifying the right specifications is critical to ensure enhanced efficiency in your applications. Key parameters such as power output, torque characteristics, and operating speed must align with the demands of your specific use case. According to a recent report by Research and Markets, the global brushless motor market is projected to reach USD 30 billion by 2025, driven by advancements in technology and increasing demand across various industrial sectors. This underscores the importance of choosing the right motor specifications to leverage modern innovations.

A significant aspect to consider is the motor's efficiency rating. Brushless motors often exhibit efficiencies of 85-95%, significantly higher than their brushed counterparts, which typically offer around 75-85%. This efficiency not only translates to lower energy costs but also improves the overall lifespan and reliability of the motor. Furthermore, understanding the thermal performance, control methods, and compatibility with your existing systems is essential. The International Electrotechnical Commission (IEC) emphasizes that selecting a motor tailored to the application can reduce energy consumption by up to 30%, showcasing the substantial impact of informed decision-making in motor selection.

| Motor Type | Rated Power (kW) | Voltage (V) | Efficiency (%) | Torque (Nm) | Speed (RPM) | Cooling Type | Weight (kg) |

|---|---|---|---|---|---|---|---|

| Permanent Magnet Brushless | 15 | 400 | 90 | 50 | 3000 | Air Cooled | 25 |

| Synchronous Brushless | 20 | 480 | 92 | 60 | 2500 | Liquid Cooled | 30 |

| AC Brushless Motor | 10 | 240 | 88 | 40 | 3500 | Natural Air | 20 |

| DC Brushless Motor | 25 | 360 | 91 | 75 | 2000 | Forced Air | 35 |

When evaluating brushless motors, understanding efficiency metrics is crucial to selecting the right model for your application. One of the primary metrics to consider is the motor's efficiency curve, which illustrates how efficiency varies with load. A brushless motor that maintains high efficiency across a wide range of loads is often preferable, as it indicates versatility and adaptability to different operating conditions. Additionally, pay attention to the efficiency rating at peak performance; a high peak efficiency can significantly enhance energy savings over time.

Another vital aspect to assess is the no-load current. A lower no-load current means that less power is consumed when the motor is not performing work, leading to greater overall efficiency. It's also important to evaluate the thermal performance; a motor that generates less heat during operation tends to have a longer lifespan and requires less energy for cooling. Finally, consider the torque-to-weight ratio; motors that provide higher torque with lower weight contribute to efficiency in both performance and energy consumption, making them an ideal choice for applications requiring robust yet lightweight solutions.

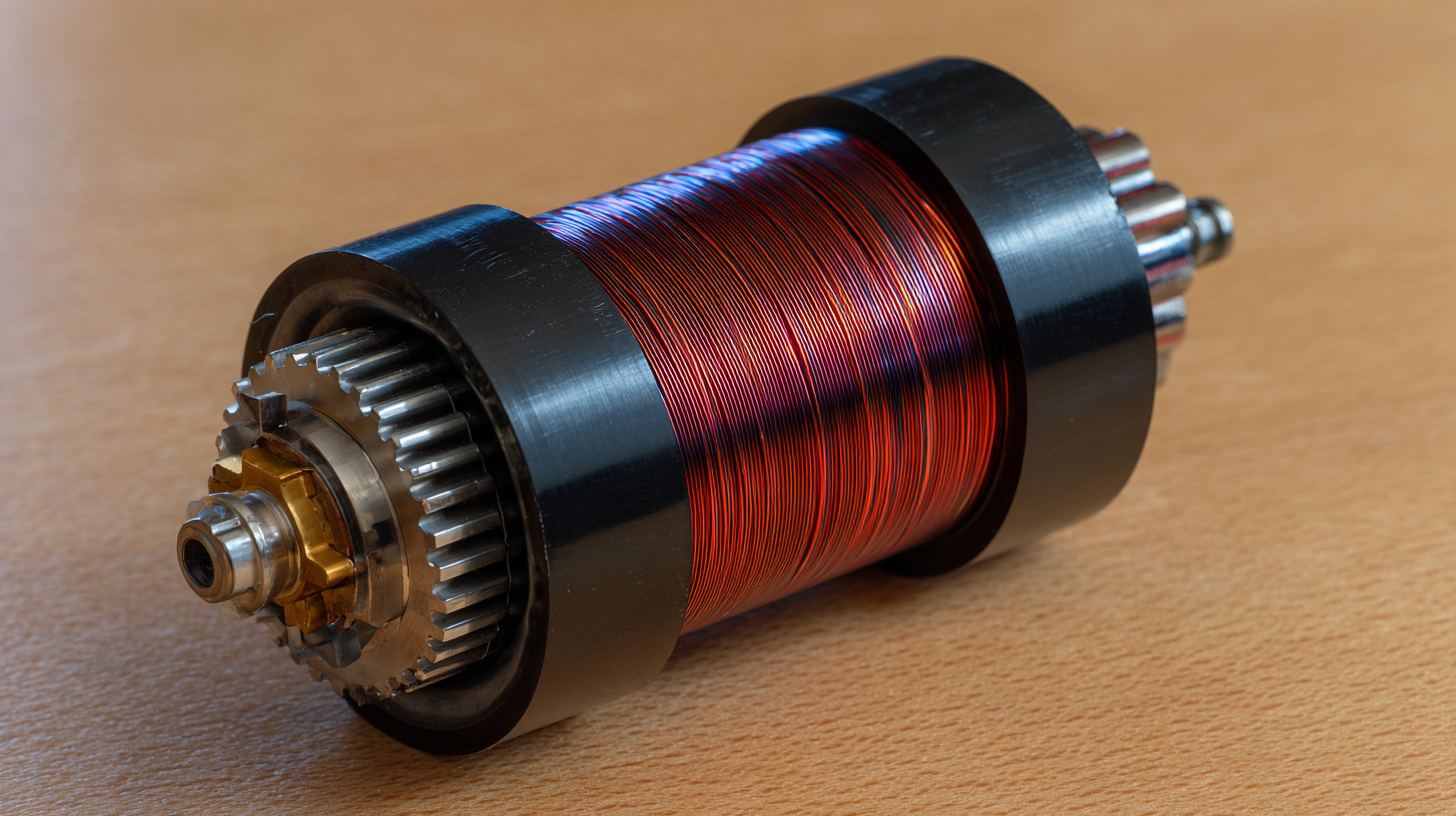

When selecting large brushless motors, understanding the different types available on the market is crucial for maximizing efficiency in applications ranging from industrial machinery to electric vehicles. According to the International Electrotechnical Commission (IEC), brushless motors are known for their high power-to-weight ratio and improved efficiency, often exceeding 90% compared to traditional brushed motors. This efficiency not only enhances performance but also contributes to lower operational costs, which is vital for businesses aiming to optimize their return on investment.

Among the various types of large brushless motors, Permanent Magnet Synchronous Motors (PMSMs) and Brushless DC Motors (BLDCs) are the most prominent. A report by Allied Market Research indicates that the global brushless motor market is projected to reach $32 billion by 2030, with PMSMs accounting for a significant share due to their superior torque characteristics and energy efficiency. Additionally, BLDCs are favored for their simple design and low maintenance, making them suitable for applications where reliability is paramount. By comparing these options, engineers can make informed decisions that align with their performance and efficiency goals, ensuring that they choose the right motor for their specific needs.

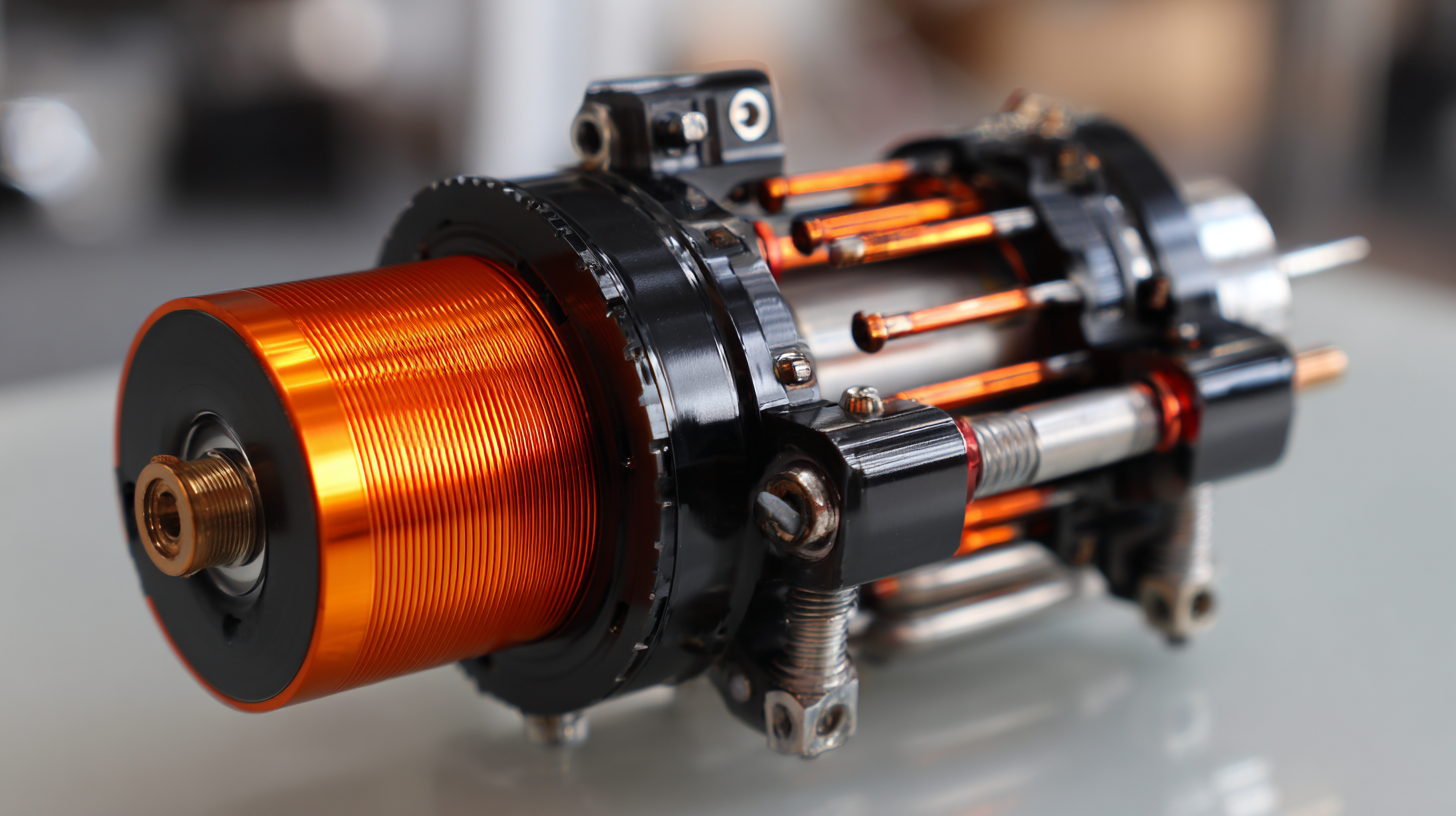

When implementing brushless motors, understanding best practices for installation and maintenance is crucial for maximizing efficiency and longevity. One of the primary considerations during installation is ensuring proper alignment and securing connections. Misalignment can lead to increased wear and tear, while loose connections might result in energy losses. Additionally, selecting the appropriate controller that matches the motor's specifications can significantly enhance performance, allowing for smoother operation and better torque management.

Regular maintenance is equally important for the optimal functioning of brushless motors. Scheduled inspections should focus on checking for signs of wear in bearings and other moving parts, as well as ensuring that the cooling systems are functioning properly to prevent overheating. Cleaning components to remove dust and debris can further prevent potential issues that could arise from contamination. Utilizing vibration analysis and thermal imaging can help detect problems early, allowing for timely interventions that can save on costly repairs and downtime. By adhering to these best practices, users can ensure their brushless motors operate at peak efficiency for an extended period.