In today's rapidly advancing technological landscape, DC brushless motors have emerged as a critical component across various industries, from consumer electronics to automotive applications. Renowned expert Dr. Emily Carter, a leading figure in motor technology, emphasizes the importance of this innovation by stating, "The efficiency and reliability of DC brushless motors are revolutionizing the way we power devices." These motors eliminate the need for brushes, resulting in less wear and extended lifespan, which is vital for applications where durability is paramount.

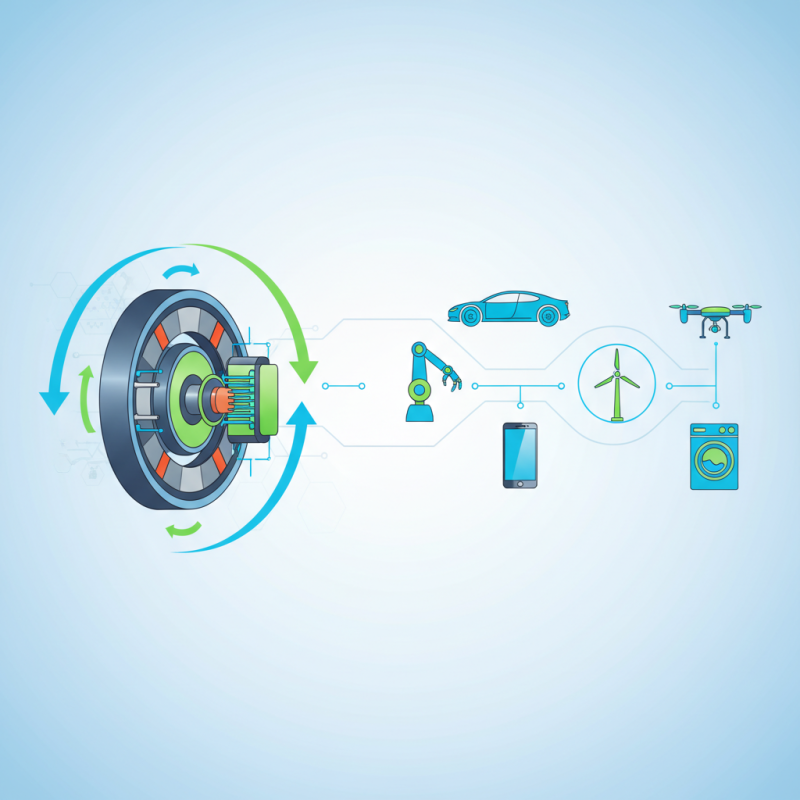

The growing emphasis on energy efficiency and high performance has led to a significant increase in the adoption of DC brushless technology. Their ability to provide precise control and efficient operation makes them an ideal choice for a wide array of applications, including robotics, aerospace, and renewable energy systems. As industries continue to seek sustainable and effective solutions, understanding DC brushless motors becomes essential not only for engineers and designers but also for anyone involved in the development of modern technologies. This guide aims to delve into the intricacies of DC brushless motors, their operational principles, and their transformative applications, providing comprehensive insights into this innovative technology.

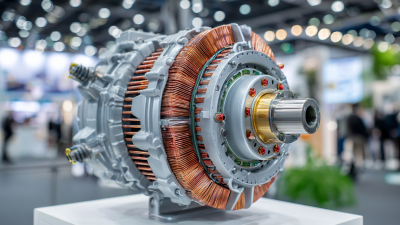

DC brushless motors have become increasingly popular in various applications due to their efficiency and reliability. Unlike traditional brushed motors, which use brushes to conduct electricity to the motor windings, brushless motors rely on electronic controllers to switch the current, providing a significant reduction in mechanical wear and tear. This design allows for higher speeds, improved torque, and extended lifespan, making them ideal for applications where durability and performance are critical.

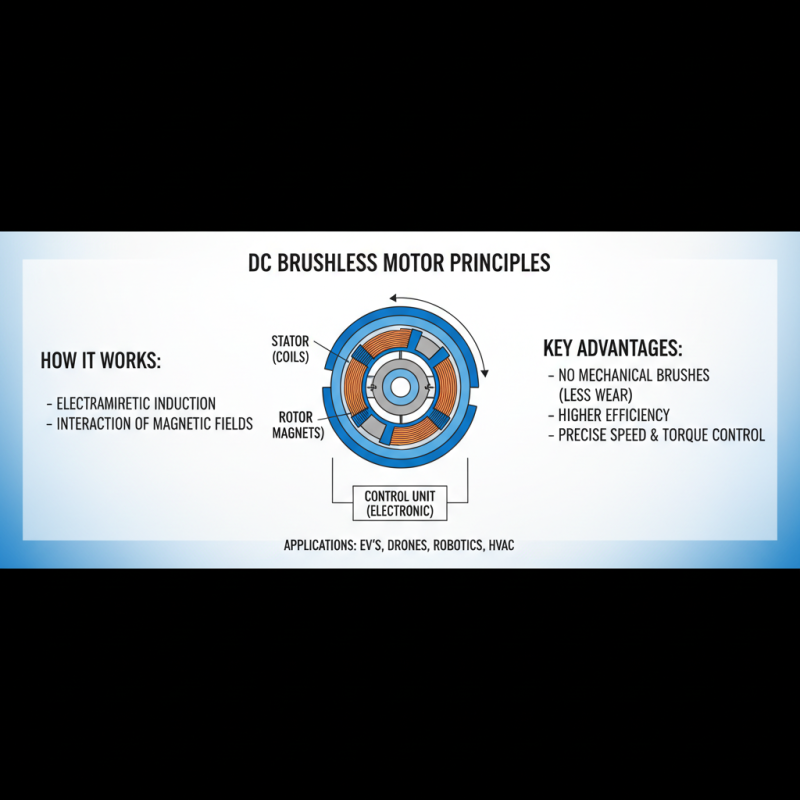

Understanding the basic components of a DC brushless motor is essential for grasping how they work. These motors consist of a rotor with permanent magnets and a stator with windings. The interaction between the magnetic fields generated by the stator and the rotor produces rotational motion. The electronic controller plays a crucial role in determining the motor’s speed and position by modulating the current supplied to the stator windings, ensuring smooth performance across various speeds. This technology has found applications in robotics, drones, electric vehicles, and various industrial machines, emphasizing its versatility and efficiency in modern machinery.

| Parameter | Description | Typical Values |

|---|---|---|

| Voltage | Operating voltage range for typical applications | 5V - 48V |

| Current | Current requirement based on load | Up to 10A |

| Speed | Operational speed measured in RPM | 1000 - 30000 RPM |

| Efficiency | Energy conversion efficiency of the motor | 80% - 95% |

| Torque | Output torque provided by the motor | 0.1 - 50 Nm |

| Applications | Typical applications where DC brushless motors are used | Robotics, Drones, HVAC systems, Electric Vehicles |

DC brushless motors operate on the principle of electromagnetic induction, where the interaction between magnetic fields produces rotational motion. Unlike traditional brushed motors, brushless designs eliminate the wear and tear associated with mechanical brushes, resulting in higher efficiency and lower maintenance requirements. The core components of a DC brushless motor include a stator, rotor, and a control unit that regulates the electrical supply to the motor. This electronic control allows for precise management of speed and torque, providing enhanced performance in various applications.

The functioning of a brushless motor revolves around the use of permanent magnets on the rotor and coils wound around the stator. When an electric current flows through the coils, it generates a magnetic field that interacts with the rotor's magnets, causing it to spin. The control unit adjusts the timing of the current in the coils, maintaining continuous rotation and optimizing performance. This setup not only enhances efficiency but also minimizes heat generation and noise, making DC brushless motors ideal for applications requiring reliability and precision, such as in robotics, electric vehicles, and aerospace technologies.

DC brushless motors are widely used in various applications due to their efficient operation and minimal maintenance requirements. At the core of these motors are several key components that work in harmony to ensure optimal performance. The most significant component is the rotor, which contains permanent magnets and rotates within the motor.

The arrangement and strength of these magnets directly influence the motor's torque and efficiency, making the design of the rotor crucial for high-performance applications.

Another essential component is the stator, which houses the winding coils. These coils produce a magnetic field when electricity is supplied, causing the rotor to turn. The configuration of the stator windings can vary, affecting the motor's speed and performance characteristics.

Additionally, controllers play a vital role in managing the power supplied to the motor. They ensure that the magnetic fields are synchronized properly, allowing for smooth operation and precise speed control. By understanding these key components, engineers can design and utilize DC brushless motors more effectively across industries ranging from aerospace to domestic appliances.

DC brushless motors are increasingly popular in various applications due to their unique advantages. One of the main benefits is their efficiency. These motors generate less heat compared to their brushed counterparts, which leads to lower energy consumption and prolonged operational life. Additionally, they require less maintenance since they do not have brushes that wear out over time. This characteristic results in lower operational costs and reduced downtime, making them ideal for applications where reliability is crucial, such as in electric vehicles and robotics.

However, there are also disadvantages to consider when using DC brushless motors. The initial cost is generally higher due to their more complex design and the need for additional electronic components for controlling the motor's operation. This can be a barrier for some smaller applications where budget constraints are a significant factor. Furthermore, while they can provide precise control over speed and torque, the control systems required can also add complexity to the overall design and implementation. Thus, while DC brushless motors offer many benefits, it is essential to weigh these against their higher cost and complexity for specific applications.

DC brushless motors have become integral across various industries due to their efficiency, reliability, and low maintenance requirements. One prominent application is in the field of HVAC systems, where these motors are used in fans and compressors. The precise control they offer leads to improved energy savings and quieter operation, making them essential in residential and commercial heating, ventilation, and air conditioning systems. Their ability to maintain consistent speed and torque enhances overall system performance.

Another significant application is found in the automotive industry, where DC brushless motors drive electric vehicles and hybrid systems. These motors facilitate smooth acceleration and energy regeneration, maximizing battery efficiency. Additionally, they are utilized in electronic power steering systems, providing drivers with enhanced control and responsiveness.

Beyond automotive, brushless motors are also prevalent in robotics and automation, where their compact design and high torque output support precise movements in robotic arms and conveyor systems. This versatility underscores the critical role of DC brushless motors in advancing technology across multiple sectors.