The demand for high-performance motors in various industrial applications is surging, driven by the need for greater efficiency and reliability. High Torque Brushless DC Motors have emerged as a critical solution in this context, offering significant advantages over traditional brushed motors. According to a recent report by ResearchAndMarkets, the global market for brushless DC motors is projected to reach $25.2 billion by 2025, with a compound annual growth rate (CAGR) of 10.8%. These motors are particularly valuable in sectors requiring precise control and high torque delivery, including robotics, electric vehicles, and manufacturing automation. Their design minimizes energy losses, resulting in enhanced performance and extended operational lifetimes, making them an attractive option for modern engineering challenges. By unlocking the potential of High Torque Brushless DC Motors, industries can not only improve efficiency but also push the boundaries of what is achievable in motion control applications.

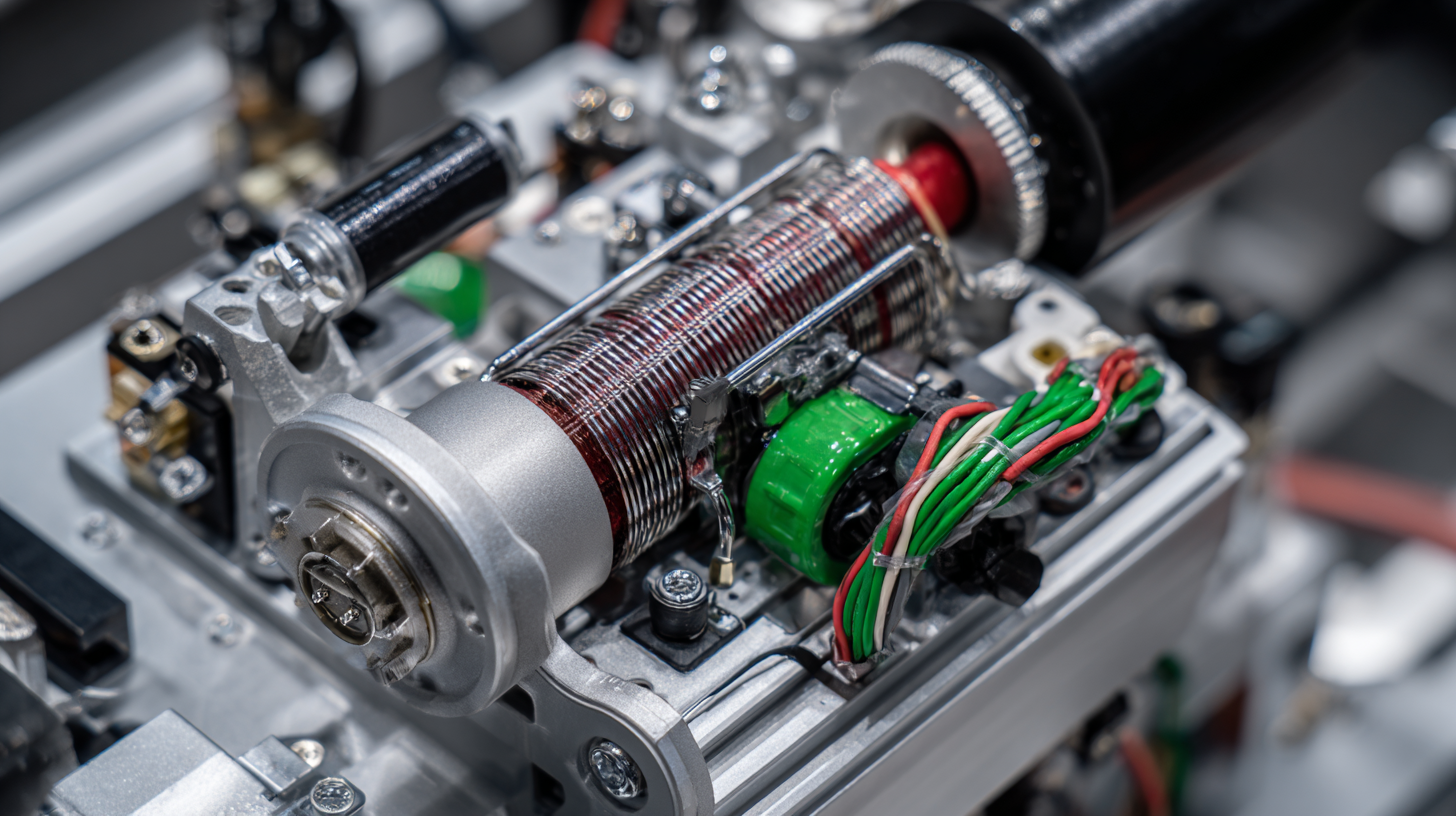

High torque brushless DC motors have emerged as a transformative technology in various applications due to their unique design and performance advantages. One of the key features of these motors is their ability to deliver substantial torque at low speeds. This characteristic is particularly beneficial in scenarios that require precise control and reliable performance, such as robotics, automation systems, and electric vehicles. The absence of brushes in these motors not only reduces mechanical wear but also enhances efficiency by minimizing energy losses.

Another significant benefit is their impressive thermal management. High torque brushless DC motors generate less heat compared to traditional brushed motors, allowing for prolonged operation without the risk of overheating. This attribute makes them ideal for high-demand applications where consistent performance is crucial. Additionally, their inherent efficiency translates to lower operational costs, as less energy is wasted during operation. As industries continue to seek innovative solutions for improved performance, high torque brushless DC motors stand out as a powerful option for enhancing productivity and efficiency across a range of applications.

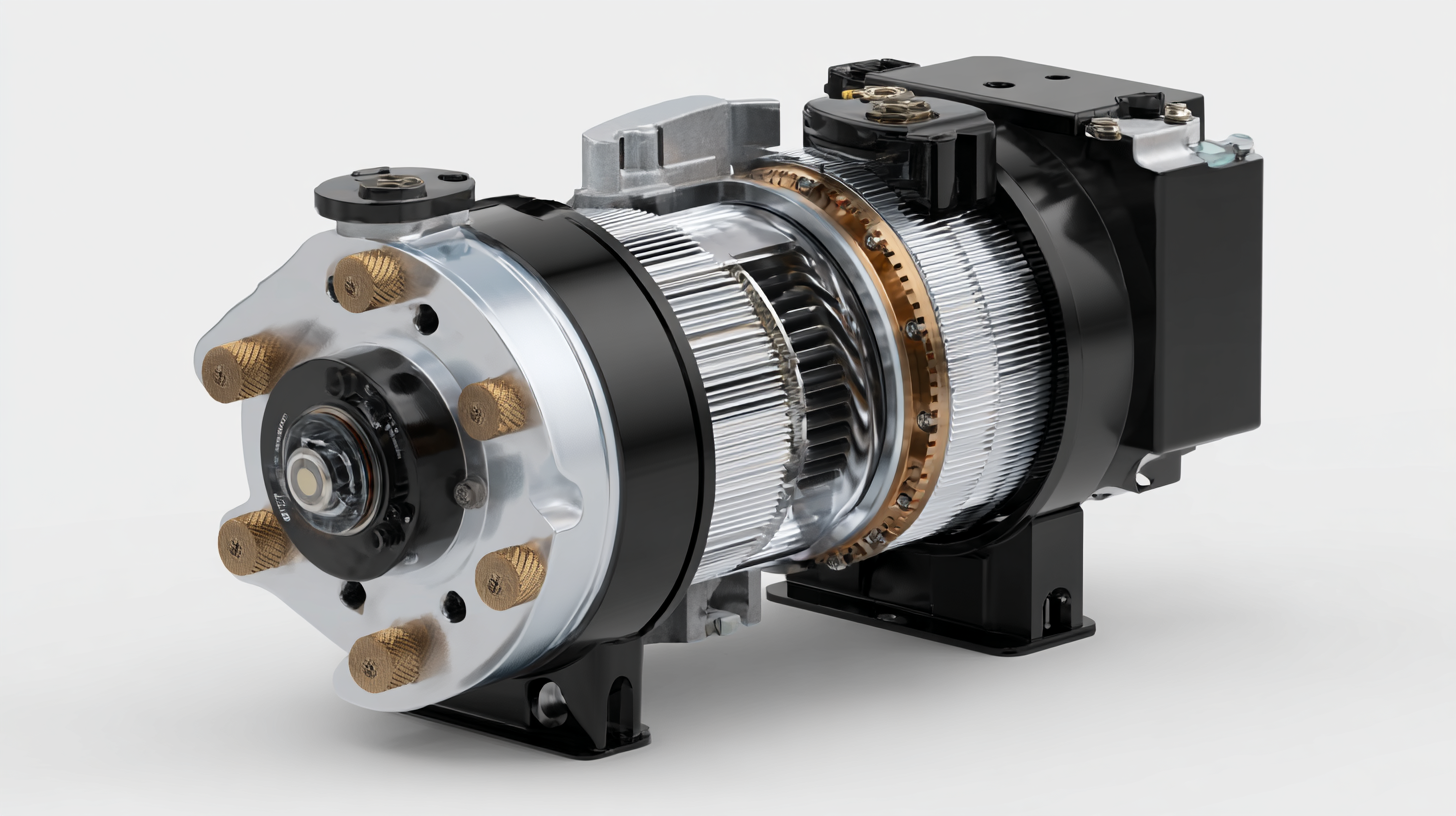

When selecting the right high torque brushless DC motor for specific applications, it's essential to consider various factors such as performance, efficiency, and environmental conditions. The global brushless DC motor market is anticipated to grow at a CAGR of 8.1% between 2025 and 2030, reaching an estimated USD 20.68 billion by 2030. This growth is largely driven by the increasing demand for high-performance motors across diverse sectors, including industrial automation and aerospace.

In industrial settings, the choice of motor can significantly impact operational efficiency. For instance, motors with enhanced torque density, such as the latest developments tailored for tough environments, can provide equivalent performance to larger motors but within a more compact design. Additionally, applications in specialized fields like aerospace benefit from the precision and durability of both slotted and slotless brushless motors, ensuring optimal performance under challenging circumstances. Therefore, understanding the requirements of your specific application is crucial for selecting the appropriate motor that maximizes both performance and efficiency.

High torque brushless DC motors are revolutionizing various industries by providing superior efficiency and performance. To truly leverage the capabilities of these motors, optimizing their operation is essential. This involves addressing several factors, from proper sizing to thoughtful integration within systems.

One key tip for maximizing efficiency is to ensure that the motor is appropriately matched to its load. Underloading or overloading the motor can lead to inefficiencies and reduced lifespan. Additionally, regular maintenance, including cleaning and periodic checks on connections, can prevent performance degradation over time.

Another important aspect is to utilize advanced control strategies. Implementing algorithms such as Field Oriented Control (FOC) can significantly enhance performance by maintaining optimal torque and minimizing losses. Adjusting the operational parameters to match specific applications can also lead to improved efficiency. By focusing on these aspects, users can unlock the full potential of high torque brushless DC motors.

When it comes to installing high torque brushless DC motors, adherence to best practices is crucial for optimizing performance and ensuring long-lasting efficiency. First, selecting the right mounting surface and orientation is essential. A stable and rigid mounting platform minimizes vibrations that could impair motor operation. Additionally, motors should be mounted in a way that allows for proper heat dissipation, considering the ambient temperatures of the installation environment.

Another important aspect is the electrical connections. Proper wiring that adheres to the manufacturer's specifications will prevent potential issues such as overheating or signal loss. Utilizing high-quality connectors and ensuring secure connections can significantly enhance the reliability of the motor system. It's also advisable to implement a thorough testing phase after installation, where you can monitor the motor’s performance under load conditions to ensure everything operates within the expected parameters. This proactive approach can help identify potential issues early, facilitating smoother and more efficient operation in the long run.

Operating high torque brushless DC motors presents several challenges that can impact performance and efficiency. One common issue is thermal management. These motors tend to generate significant heat during operation, which can lead to overheating and eventual failure if not properly managed. Implementing effective cooling systems, such as heat sinks or forced air cooling, can mitigate this issue and extend the lifespan of the motor.

Another challenge is achieving precise control over torque output. High torque brushless DC motors require advanced control algorithms to maintain optimal performance under varying load conditions. Depending on the application, using field-oriented control (FOC) or other sophisticated techniques can help improve responsiveness and maintain desired torque levels. Additionally, proper tuning of the motor controller is essential to minimize overshoot and stabilize performance in dynamic conditions, ensuring the motor operates efficiently and reliably.