When embarking on a project that requires power and precision, selecting the right motor is crucial. D.C. motors, especially those boasting high torque, stand out for their reliability and efficiency. The term "Dc Motor High Torque" often appears in discussions on optimal choices for various applications. From robotics to manufacturing, high torque DC motors can significantly enhance performance.

High torque motors generate a substantial amount of rotational force. This ability enables them to handle heavier loads with ease. Whether it's a small gadget or a large machinery component, these motors are versatile. However, choosing one isn't always straightforward. You might face challenges in matching the motor's specifications to your project needs. Understanding the power requirements and load conditions is essential.

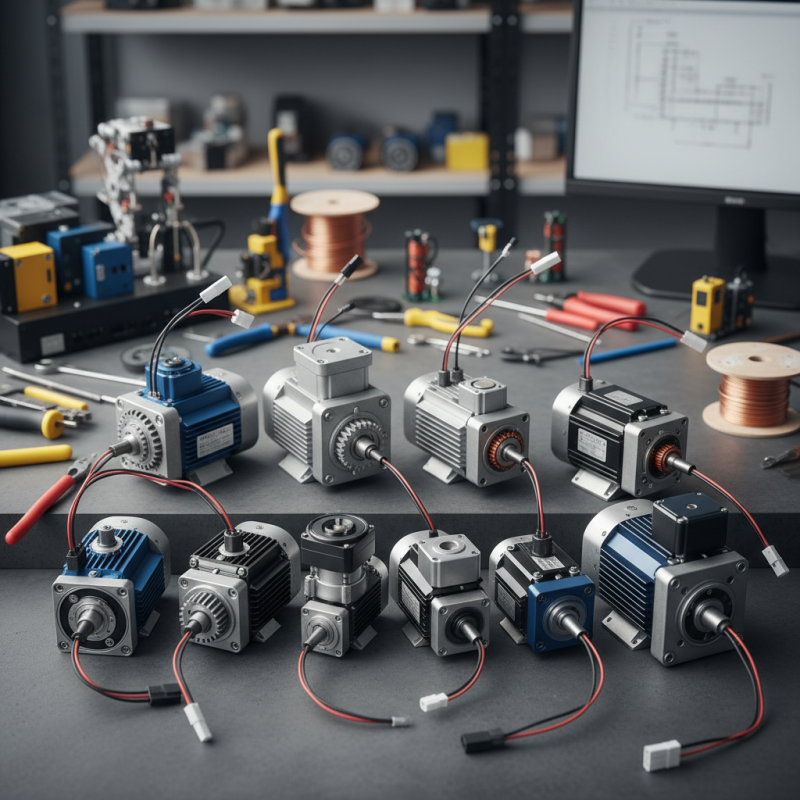

There are numerous options available, each with distinct features. This variety can be overwhelming, leading to potential mistakes in selection. It's vital to reflect on your project's unique demands and constraints. Let's explore the top 10 high torque DC motors suitable for your next endeavor. By doing so, we can avoid common pitfalls and ensure optimal outcomes.

High torque DC motors are essential in various applications. They provide the power needed for mechanical tasks. These motors are used in robotics, automotive systems, and industrial machinery. Reports indicate that high torque motors can deliver torque up to 5 Nm or more. This capability makes them ideal for heavy lifting tasks.

When selecting a high torque motor, consider your project requirements. Power ratings and efficiency are crucial. Look for motors with a torque-speed curve that fits your needs. Not all motors perform well in every scenario. Testing different models can help identify the best fit.

Tip: Always examine the motor's thermal management. High torque can lead to overheating. Protecting your motor from excessive heat prolongs its lifespan. Be mindful of the workload you put on your motor. Overworking it can reduce efficiency and damage components.

High torque DC motors have diverse applications. They can be found in conveyor systems and robotic arms. Each application may require different specifications. Researching industry standards is recommended. Doing so can guide you in making informed decisions.

Torque is crucial when selecting a DC motor for your projects. It determines how much rotational force the motor can generate. A motor with high torque can handle heavier loads without stalling or slowing down. This aspect is vital for applications like robotics and conveyor systems, where precise movement is key.

According to industry reports, motors capable of delivering upwards of 1 Nm of torque are becoming popular for many engineering applications. This high torque is necessary for tasks that require strength and reliability. In contrast, low torque motors often struggle under load, leading to inefficiency. When considering torque, remember that it's not just about power; it’s about the motor's ability to maintain consistent performance.

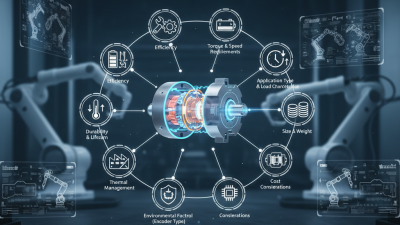

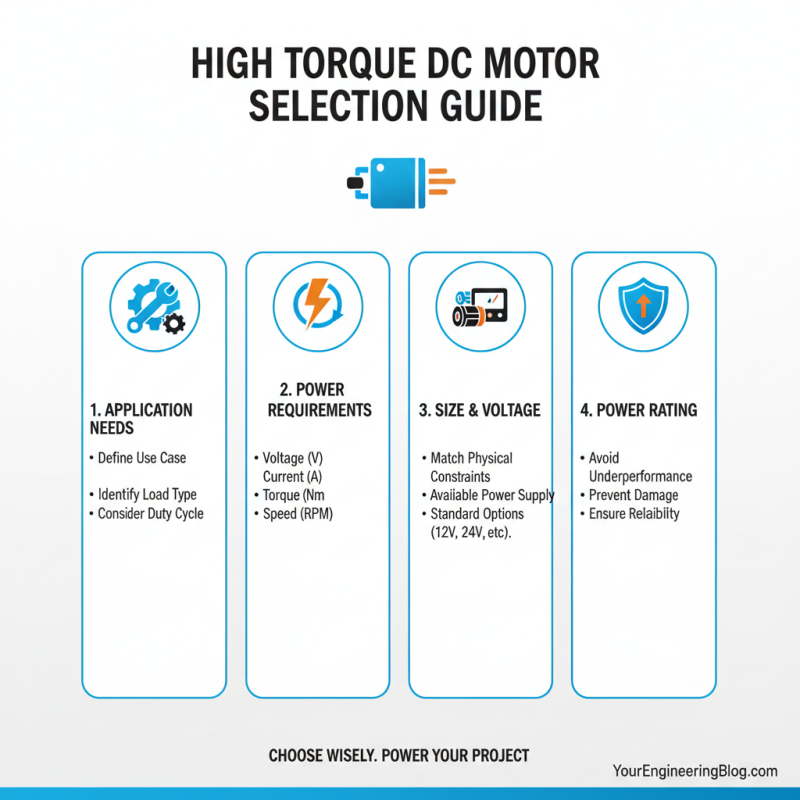

When selecting a high torque DC motor, consider the application’s specific needs. Understanding the power requirements is crucial. High torque motors come in various sizes and voltages. Choose one that aligns with your project. Evaluating the power rating helps avoid underperformance or damage.

Another important factor is the speed range. Too high of a speed might lead to instability. Conversely, too low may hinder functionality. The motor’s physical dimensions also matter. Ensure your chosen motor fits within the project's constraints. Adequate space for heat dissipation is necessary, so check for that too.

Durability is a key aspect to reflect on. Look for motors built with high-quality materials. Testing under real conditions can reveal performance issues. Find motors with feedback systems, as they provide better control. This can improve efficiency in your project. Ultimately, take your time to assess all these factors thoroughly. The right choice can make or break your project’s success.

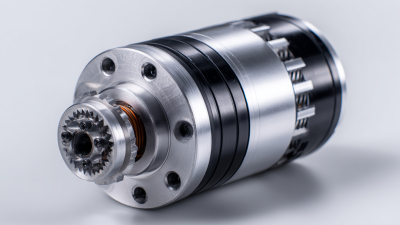

When selecting a high torque DC motor for your project, understanding key features is crucial. Look for motors with robust construction, as durability often correlates with performance. Ensure the motor has a suitable voltage and current rating for your needs. High torque motors often feature gearboxes, multiplying their output power. This is essential for applications requiring significant strength.

One tip is to match the motor's torque ratings with your project requirements. Calculate the load to avoid overloading the motor. Overloading can lead to inefficiencies and failures. Consider the application’s duty cycle; continuous use can heat up motors significantly. Excess heat can reduce the motor's lifespan.

Many high torque motors come with specific mounting options. This can simplify installation but may also limit flexibility. Evaluate your design to ensure compatibility. If unsure, consult datasheets. Be meticulous about the specifications. Each detail can affect performance. Sometimes, a slightly lower torque motor can work better in a lighter application.

High torque DC motors are evolving rapidly. Their applications are expanding across various industries. Robotics is one significant area. These motors provide the necessary power for precise movements. Manufacturers are pushing the limits on torque output. This enables new designs and functionalities.

Technological advancements focus on efficiency and control. Sensor integration enhances performance. This allows for real-time adjustments. In many cases, designers struggle with balancing torque and speed. It's crucial to select the right specifications for your project. Failure to do so can lead to inefficiencies.

Another interesting trend is the rise of compact designs. Smaller motors with high torque are becoming popular. They take up less space but still provide robust performance. However, not all compact models work efficiently in every application. Users must be cautious when choosing these motors. Always consider the specific project demands and environment.