Choosing the right BLDC servo motor can be challenging. As John Smith, an industry expert, once stated, "The key is to match specifications with application needs." This advice reflects how crucial it is to understand your project requirements.

BLDC servo motors are often favored for their efficiency and precision. However, not every motor fits every project. Consider the torque, speed, and size. Each project demands different specifications. Understanding these elements can be a turning point in your design process.

Many factors can complicate this choice. It’s easy to overlook power supply or compatibility issues. These oversights can lead to unexpected setbacks. Reflecting on past projects can provide valuable insights. Consider what worked and what didn’t. This helps in making a more informed decision.

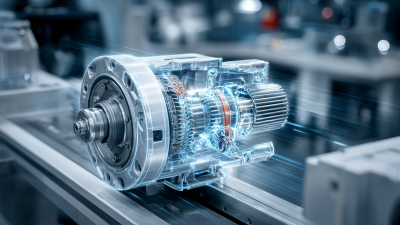

Understanding BLDC Servo Motors: Basics and Applications

BLDC (Brushless Direct Current) servo motors are popular due to their efficiency and reliability. These motors use electronic commutation instead of mechanical brushes. This design helps reduce wear and tear, enhancing longevity. They are crucial in various applications, including robotics and automation. Thus, understanding their basics can lead to better project outcomes.

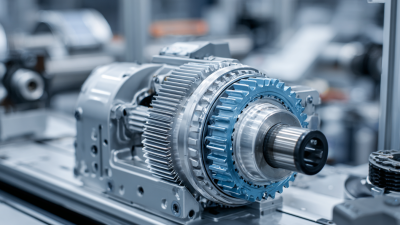

Here are some tips when selecting a BLDC servo motor. First, consider your torque and speed requirements. Motors have different specifications based on their design. Matching the motor's rating to your project's needs is crucial. Also, be mindful of the operating environment. Dust, moisture, and temperature can affect performance.

Another crucial factor is driver compatibility. Ensure that the motor aligns with your controller. Sometimes, mismatches can result in inefficiencies or failures. Testing the motor under real conditions reveals hidden issues. Frequent adjustments may be necessary as projects evolve. Taking these details into account will lead to better performance and fewer frustrations.

| Parameter | Description | Value Example |

|---|---|---|

| Voltage | The operating voltage of the motor | 24V |

| Continuous Torque | The maximum continuous torque the motor can deliver | 0.5 Nm |

| Peak Torque | The maximum torque for short durations | 1.2 Nm |

| Speed | The maximum rotational speed of the motor | 3000 RPM |

| Encoder Type | Type of encoder for feedback | Incremental |

| Protection Class | The protection level against dust and water | IP65 |

| Weight | The weight of the motor | 1.5 kg |

| Operating Temperature | The temperature range where the motor operates | -20°C to +60°C |

Choosing the right BLDC (Brushless DC) servo motor can be a daunting task. Key specifications greatly influence the performance of your project. Torque specifications are critical. High torque is needed for heavy loads. Ensure you assess the required torque for your application. Additionally, consider the motor's speed. Different applications may require varying speeds. Match the speed rating to your project's needs.

Another important aspect is the motor’s size and weight. A compact design can save space but might limit power. Weigh the trade-offs between size and performance. Check the voltage range as well. Not all motors can operate at the same voltage. Operating outside the specified range can damage the motor.

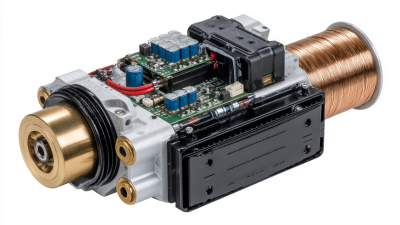

Look closely at feedback systems. Some motors offer encoders for precise position control. Others may not, affecting your project’s accuracy. Not all systems require high precision. However, consider future needs, too. You might need more accuracy later on. Lastly, be mindful of your budget. Finding a balance between quality and cost is tricky. Not every expensive motor guarantees superior performance. Careful consideration of each specification will guide you to the right choice.

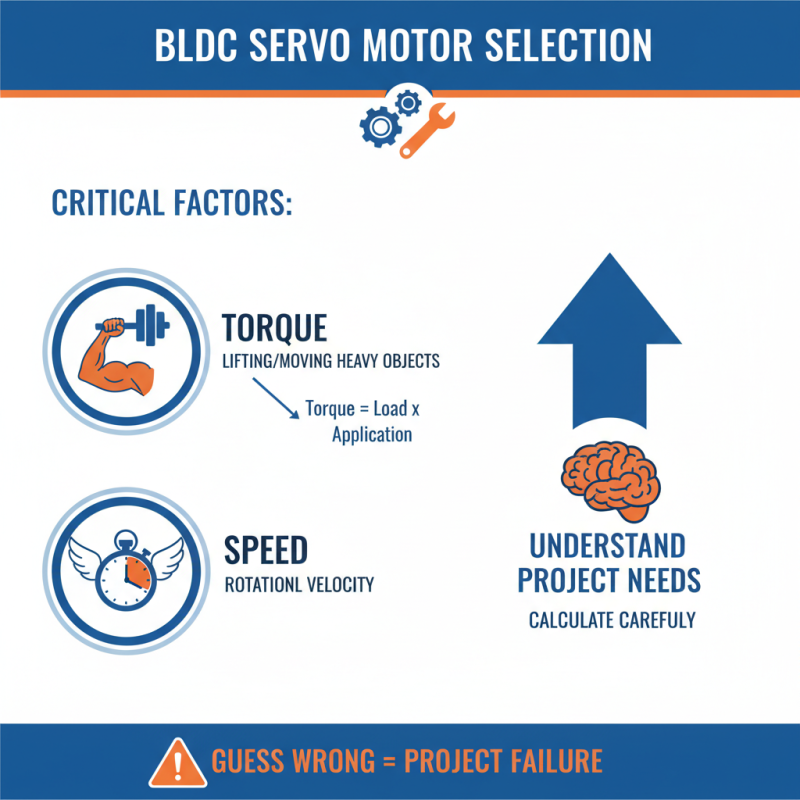

When choosing a BLDC servo motor, torque and speed are critical factors. Understand your project's specific needs. Torque determines how much weight your motor can handle. It’s essential for tasks that require lifting or moving heavy objects. Calculate the needed torque based on the load and the application. If you guess wrong, your project may fail.

Speed is equally important. It refers to how fast the motor can turn. If your application requires rapid movement, select a motor with high RPM ratings. Conversely, some projects need slower, more controlled movements. Finding balance is key. A high-speed motor might not provide enough torque for heavy loads.

Consider the environment too. Operating conditions can impact performance. An outdoor project may need motors resistant to dust and moisture. Always reflect on these choices. Rushing the selection can lead to unforeseen issues later. Make adjustments based on real-time feedback and test results. Use prototyping to address potential shortcomings before finalizing your design.

When selecting a BLDC servo motor, evaluating control methods is crucial. Different applications demand various control strategies such as torque control or position control. The control method should align with your project's requirements. For example, a position control method can benefit robotics, allowing precise movements. Torque control is essential for applications needing consistent force output, like conveyor systems.

Tips: Always test your control strategy. Small adjustments can optimize performance. You might find that your initial choice doesn't suit the motor's capabilities.

Compatibility with your existing system is another key factor. Ensure that the motor interfaces well with your system's voltage and current ratings. Different systems also use various communication protocols. Make sure the motor can work with your controller. This could save time and costs later.

Tips: Review your system's specs thoroughly. Consider challenging compatibility issues beforehand. Ignoring these can lead to performance problems.

When budgeting for BLDC servo motors, it's essential to consider various cost factors. The initial price is just one aspect. Factors such as efficiency, lifespan, and application requirements significantly impact total expenses. A recent industry report indicates that high-efficiency models can reduce energy costs by up to 30%. This saving can offset a higher initial investment over time.

Installation costs also deserve attention. Precision bonding and alignment are crucial for optimal performance. Skimping on installation may lead to increased downtime and maintenance, causing unexpected costs. Some sources estimate that improper installation can inflate operational costs by an additional 15-20%.

Maintenance and replacement parts should not be overlooked. Regular maintenance can prevent costly failures, yet the initial costs may seem high. The balance between upfront and long-term costs requires careful evaluation. Companies often underestimate long-term expenses, leading to budget overruns. Planning for these factors can ensure a more accurate budget.