In the rapidly evolving world of engineering and technology, the choice of motor type can significantly impact the performance and efficiency of any project. Compact DC motors have emerged as a preferred option among engineers and designers thanks to their numerous advantages. According to Dr. Emily Grant, a leading expert in motor technology, "Compact DC motors offer a unique blend of efficiency, versatility, and size that is unmatched in the current market." This statement encapsulates the reason why many professionals are turning to compact DC motors for their applications.

The benefits of utilizing compact DC motors extend far beyond their physical dimensions. Their lightweight and space-saving design not only makes them easier to integrate into smaller projects, but they also deliver robust performance, high speed, and precise control. This combination of features positions compact DC motors as an ideal solution for automotive, robotics, and consumer electronics applications. As we delve deeper into the key benefits of choosing compact DC motors, it becomes evident that they represent a smart investment for future-focused engineering endeavors, enhancing both innovation and efficiency.

Compact DC motors have gained significant traction in modern applications, primarily due to their unique advantages that cater to the evolving demands of industries. One of the key benefits of these motors is their high power-to-weight ratio. According to a report by the International Electrotechnical Commission, compact DC motors typically offer up to 30% more efficiency in restricted spaces compared to traditional alternatives. This efficiency allows engineers to incorporate motors into designs where space is at a premium, enabling more innovative products across sectors such as robotics and automotive engineering.

Moreover, the versatility of compact DC motors enhances their appeal in various applications. They can be easily integrated into automation systems and are well-suited for tasks requiring precise speed and torque control. A study by the IEEE highlighted that automation using compact motors can boost production efficiency by up to 25%, translating into substantial cost savings. Additionally, their lightweight design contributes to lower energy consumption, making them an eco-friendly choice in an era where sustainability is increasingly prioritized by businesses and consumers alike. This combination of efficiency, flexibility, and environmental consideration positions compact DC motors as a preferred solution in modern engineering projects.

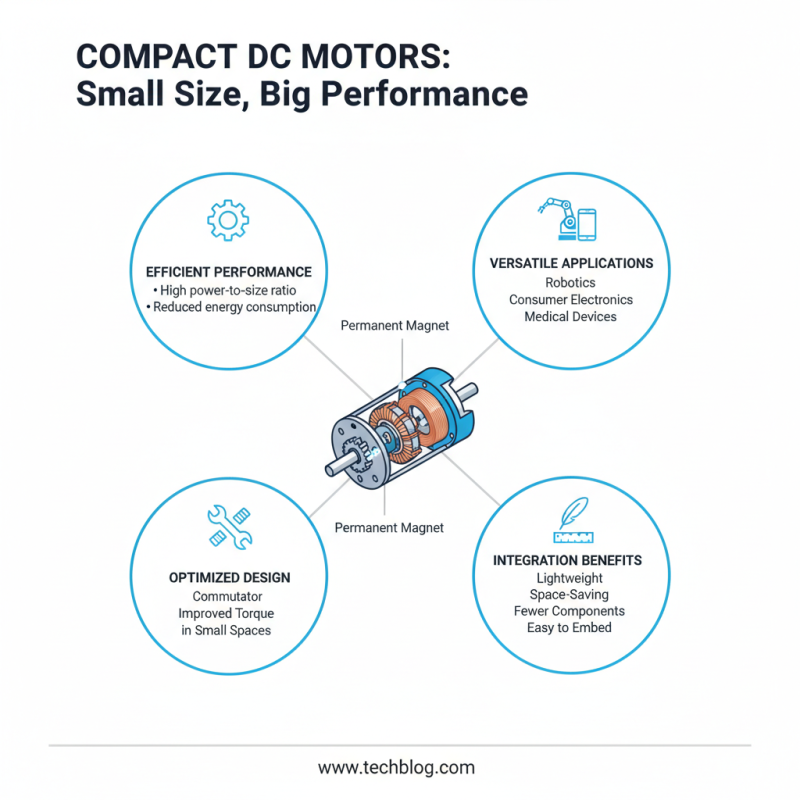

Compact DC motors are engineered to deliver efficient performance in a small form factor, making them an ideal choice for various applications, from robotics to consumer electronics. The design of these motors typically involves a permanent magnet and a commutator, which convert electrical energy into mechanical motion. This configuration not only enhances their efficiency but also allows for improved torque generation in limited spaces. As they are lightweight and have fewer components, compact DC motors can be integrated easily into systems where weight and size are critical constraints.

Functionality-wise, compact DC motors excel due to their ability to provide precise control over speed and positioning. They can be easily modulated using pulse-width modulation (PWM) techniques, which enables fine-tuning of performance according to the demands of the project. Additionally, their simple installation and maintenance requirements make them practical for both prototype development and large-scale production. With their versatility and reliable operational characteristics, compact DC motors are a staple in innovative designs that require high performance without compromising spatial efficiency.

Compact DC motors are increasingly recognized for their energy efficiency, making them a preferred choice for environmentally conscious projects. These motors are designed to convert electrical energy into mechanical energy with minimal losses, which translates to lower energy consumption during operation. Their high efficiency not only reduces power requirements but also contributes to decreased greenhouse gas emissions. This is particularly significant in applications where multiple motors are used, as the cumulative energy savings can lead to a substantial reduction in a project's overall carbon footprint.

Moreover, the compact size of these motors means they can be integrated into a variety of applications without occupying excessive space. This versatility allows for the design of more efficient systems that optimize resource use. By utilizing compact DC motors, engineers can create more sustainable products that align with modern environmental standards. The reduced power consumption and smaller size also lead to less heat generation, further improving overall system performance and longevity. Incorporating these motors into future projects not only benefits the environment but also enhances the feasibility and sustainability of technological solutions.

Compact DC motors are renowned for their versatility, making them indispensable across various industries. These motors can be found in applications ranging from automotive systems to consumer electronics. In the automotive sector, compact DC motors power essential functions like power windows, seat adjustments, and windshield wipers, enhancing user convenience and safety. Their lightweight design allows for efficient integration into tight spaces, making them ideal for modern vehicle engineering.

In the industrial realm, compact DC motors contribute significantly to automation and robotics. Their precise control and responsiveness make them perfect for tasks such as conveyor belt systems, robotic arms, and manufacturing machinery. These motors facilitate smooth and accurate operations, leading to increased productivity and decreased downtime. Additionally, in the medical field, compact DC motors play a critical role in devices like surgical tools and patient care equipment, where reliability and efficiency are paramount. This broad range of applications highlights the adaptability of compact DC motors, demonstrating their value across diverse sectors.

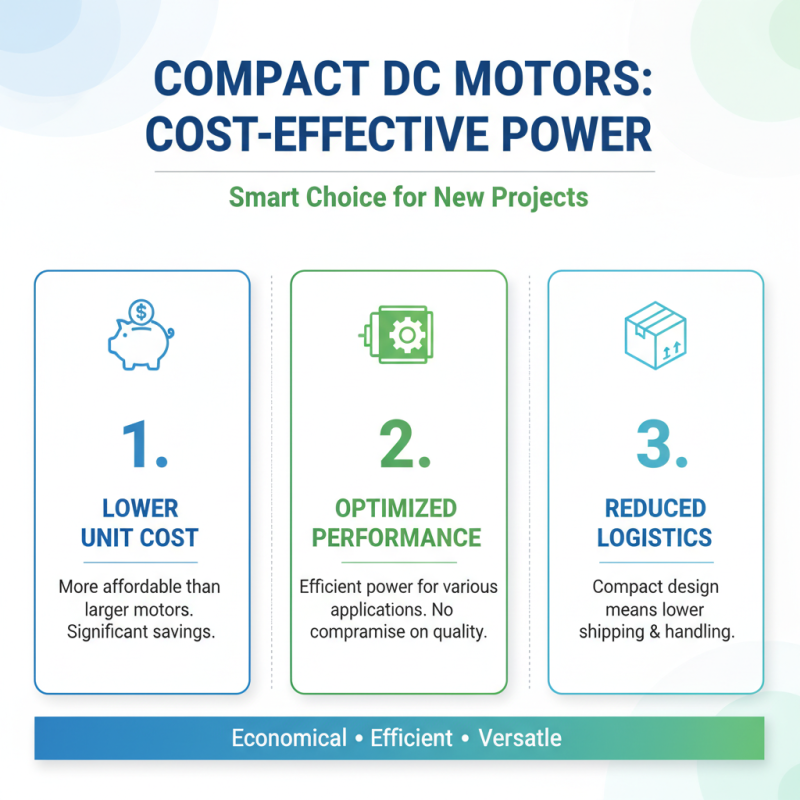

When embarking on a new project, budget considerations are often at the forefront of decision-making processes. Compact DC motors stand out as a cost-effective solution, especially when weighed against the demands of various applications. These motors are typically more affordable than their larger counterparts, allowing for significant savings without compromising on performance. Additionally, their compact design results in lower shipping and handling costs, making them an economical choice for manufacturers and hobbyists alike.

Furthermore, the efficiency of compact DC motors contributes to long-term financial benefits. Unlike larger motors, which might consume more energy or require extensive maintenance, compact DC motors often operate effectively within tighter power budgets. This translates to lower energy bills and reduced operational costs over the lifespan of the project. By adopting compact DC motors, one can achieve a balance of quality and cost, ensuring that the project remains within budget while still meeting performance and reliability expectations.