The efficient performance of machinery is paramount in today's competitive industrial landscape, and Bldc Servo Motor technology has emerged as a key player in optimizing this performance. According to a report by Markets and Markets, the global servo motors and drives market, which includes Bldc technologies, is projected to reach USD 14.72 billion by 2025, growing at a CAGR of 6.29% from 2020. This growth is driven by the increasing demand for precision and reliability in automation across various sectors, such as manufacturing and robotics.

Bldc Servo Motors offer advantages such as higher efficiency, durability, and reduced maintenance costs, making them ideal for applications that require high-speed and precise motion control. By leveraging these advanced motor technologies, businesses can enhance productivity, reduce energy consumption, and achieve greater operational excellence.

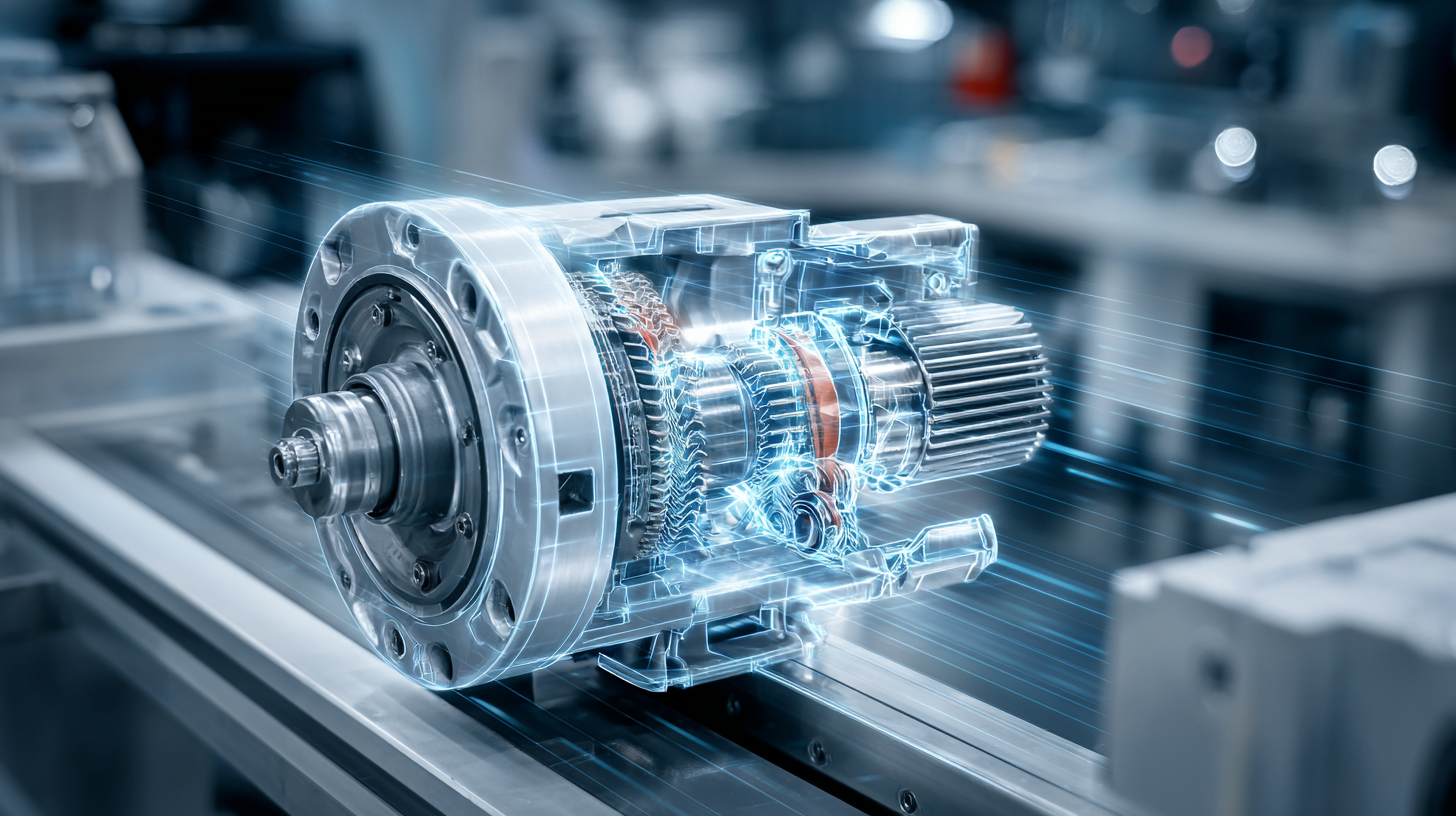

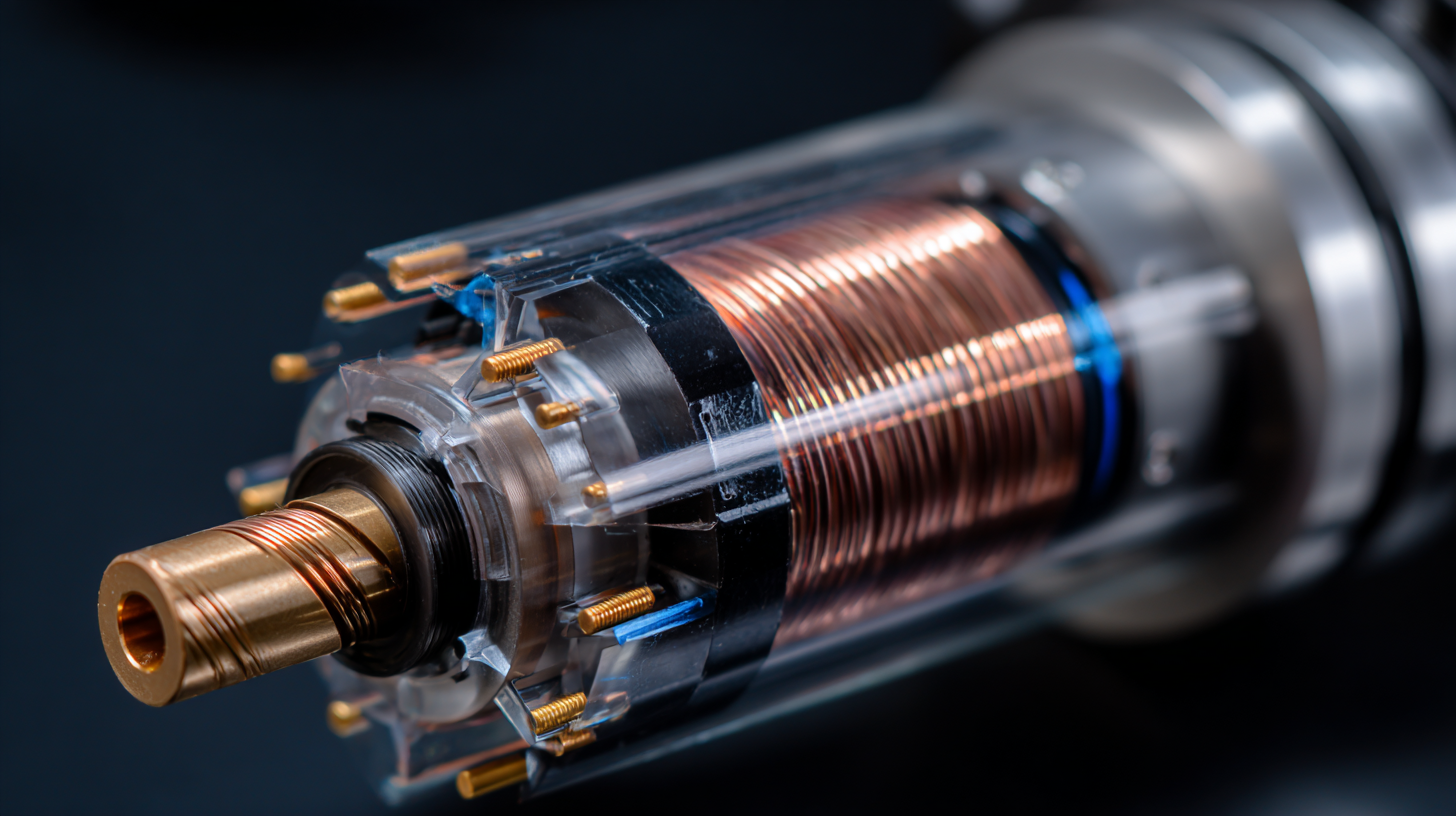

BLDC (Brushless Direct Current) servo motor technology has revolutionized the way machinery operates by providing high efficiency and precision. Understanding the fundamentals of this technology is crucial for optimizing machinery performance. BLDC motors use electronic commutation instead of mechanical brushes, which reduces wear and tear, leading to longer lifespans and lower maintenance costs. This technology also enhances control over speed and torque, making it ideal for applications that require high-performance automation, such as robotics and CNC machines.

The design of BLDC servo motors allows for excellent control and adaptability, responding rapidly to changes in operational demands. They are equipped with sensors that monitor rotor position, enabling precise control over motor movement. Moreover, the integration of advanced algorithms allows for improved torque production and energy efficiency. By leveraging these benefits, manufacturers can achieve smoother operation and increased productivity in their machinery, ultimately leading to improved output and reduced downtime. Understanding these fundamental aspects of BLDC servo motors is essential for any professional looking to enhance machinery performance and stay competitive in today's fast-paced industrial landscape.

The integration of Brushless DC (BLDC) servo motors into machinery offers significant advantages that enhance performance and efficiency. One of the primary benefits is their ability to provide precise control over motor functions. This precision translates into improved accuracy in operations, which is critical in sectors requiring high standards, such as robotics and automation. Additionally, BLDC motors are known for their superior torque-to-weight ratio, enabling machines to operate efficiently without excessive energy consumption, which is increasingly essential in today's energy-conscious environment.

Furthermore, the durability and low maintenance requirements of BLDC servo motors contribute to their growing popularity across various industries. Their lack of brushes reduces friction and wear, resulting in a longer lifespan and reduced downtime for machinery. As a result, manufacturers can achieve smoother operations and lower operational costs, making BLDC technology an attractive investment. This trend is reflected in the projected growth of the global brushless DC motor market, emphasizing the pivotal role these motors play in advancing machinery performance.

| Feature | Traditional Motors | BLDC Servo Motors |

|---|---|---|

| Energy Efficiency | Low (60-70%) | High (85-95%) |

| Control Precision | Medium | High |

| Maintenance Cost | High | Low |

| Noise Level | High | Low |

| Size/Weight | Large | Compact |

| Heat Generation | High | Low |

| Response Time | Slow | Fast |

When optimizing machinery performance with Brushless DC (BLDC) servo motors, several key factors come into play. First and foremost, it's essential to consider the motor's specifications, including torque, speed, and power efficiency. Selecting a motor that meets specific operational demands will enhance overall productivity and maintain energy efficiency, which can lead to significant cost savings. The right balance between these parameters ensures that machinery operates smoothly while providing the necessary force and speed for various applications, from simple tasks to complex industrial processes.

Another crucial factor is the control system used in conjunction with BLDC motors. Implementing advanced control algorithms can greatly improve responsiveness and accuracy in motion control. For instance, field-oriented control (FOC) can provide better torque performance and efficiency at various speeds. Additionally, integrating feedback systems such as encoders allows for real-time monitoring of performance, ensuring that the motor operates within optimal parameters for enhanced reliability. By focusing on these aspects—motor choice and control strategies—manufacturers can achieve exceptional performance and longevity from their machinery.

Maintaining and troubleshooting BLDC (Brushless DC) servo systems is critical for optimizing machinery performance. According to a report by Allied Market Research, the global market for servo motors, particularly BLDC types, is projected to reach $12 billion by 2025, driven by their efficiency and precision in applications ranging from robotics to conveyor systems. Regular maintenance practices are pivotal; for instance, keeping the motor and controller clean, ensuring proper lubrication of moving parts, and regularly checking for signs of wear can significantly prolong the lifespan of the equipment and prevent sudden failures.

In terms of troubleshooting, common issues can stem from electrical faults, such as inconsistent power supply or poor connections, which account for nearly 30% of servo system malfunctions, as reported by the International Society of Automation. Utilizing advanced diagnostic tools and software can help operators quickly identify and rectify these faults. Furthermore, implementing a predictive maintenance strategy, based on real-time data analytics, can enhance operational reliability, making it an essential practice in modern manufacturing setups where downtime can lead to significant cost implications.

The future of BLDC (Brushless DC) servo motor technology is set to redefine the landscape of machinery optimization. According to a report by ResearchAndMarkets, the global BLDC motor market is expected to grow to $41.6 billion by 2026, driven by increasing demand for energy-efficient solutions across various industries. This growth is primarily fueled by advancements in electronic control systems and the integration of IoT technologies, enabling precise control and monitoring of machinery performance. With the adoption of BLDC motors, industries can achieve significant energy savings and reduce maintenance costs due to their longer operational lifespans.

To optimize machinery performance effectively, users should consider implementing real-time data analytics. By leveraging predictive maintenance tools, organizations can foresee potential failures, thus minimizing downtime. Tips for optimizing machine efficiency include regularly calibrating servo motors to ensure peak performance and considering adaptive control strategies that respond to changing load conditions. Furthermore, investing in advanced sensor technology can provide crucial feedback for maintaining optimal operating conditions.

As we look ahead, the focus on sustainability will only amplify the adoption of BLDC servo motors. Reports indicate that by 2030, electric motors will account for almost 50% of total energy use in industrial processes. This shift not only emphasizes the need for greater energy efficiency but also encourages the development of more intelligent machinery. Embracing these trends will not only enhance operational efficiency but also contribute to eco-friendly practices in manufacturing.