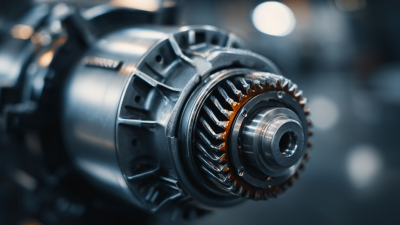

Selecting the right motor for your project is crucial, especially when it comes to applications requiring significant power and efficiency. The High Torque BLDC Motor has emerged as a popular choice due to its superior performance characteristics compared to traditional brushed motors. With advantages such as lower maintenance, higher efficiency, and a more compact design, these motors are ideally suited for a wide range of applications, from robotics to automotive technologies.

However, choosing the correct High Torque BLDC Motor can be a challenging task, as there are various factors to consider, including torque requirements, speed, size, and operational environment. Understanding the specific needs of your project is essential to ensure optimal performance and reliability. This introduction aims to guide you through the key considerations and parameters that will help you make an informed decision, ultimately leading to the successful implementation of your design.

High torque BLDC (Brushless DC) motors have emerged as essential components in various applications due to their reliability, efficiency, and performance. These motors are particularly utilized in areas requiring high starting torque and smooth operation, such as robotics, automotive systems, and industrial automation. According to a report by Research and Markets, the global brushless DC motor market is projected to reach $28.5 billion by 2027, underscoring the growing reliance on high torque capabilities across multiple sectors.

One significant advantage of high torque BLDC motors is their high power-to-weight ratio, making them suitable for lightweight and compact applications. For instance, in the aerospace industry, the high torque output allows engineers to design lighter aircraft components without sacrificing performance or safety. Moreover, their ability to provide constant torque over a wide range of speeds makes them ideal for precision applications, such as CNC machines and electric vehicles, where efficiency and control are crucial. The increasing trend towards automation and the demand for more efficient drive systems fuel the adoption of these motors, reflecting a shift in industrial practices toward enhanced energy efficiency and reduced operational costs.

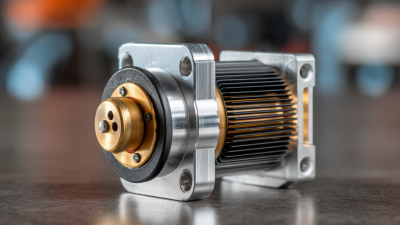

When selecting a high torque BLDC motor for your project, there are several key specifications to consider to ensure optimal performance. One of the most crucial factors is the torque rating, which determines the motor's ability to drive the load effectively. A higher torque rating allows the motor to handle increased load, making it essential for applications requiring significant force. Additionally, consider the motor's efficiency, which impacts power consumption and operational costs. A motor that operates efficiently will reduce energy waste and prolong battery life in portable applications.

Another important specification is the voltage rating, which influences the motor's power output and compatibility with your system. Ensure that the voltage matches your project requirements to prevent operational issues. The motor's speed range is also critical; understanding the required RPM (rotations per minute) for your application will help you select a motor that meets performance expectations.

**Tips:** Always evaluate the operational environment of the motor. Factors such as temperature, humidity, and exposure to dust or moisture can affect motor performance. Additionally, consider the control method you plan to use, as some motors may require specific controllers for optimal operation. Finally, taking time to review and compare different motors will help you make an informed decision that aligns with your project’s goals.

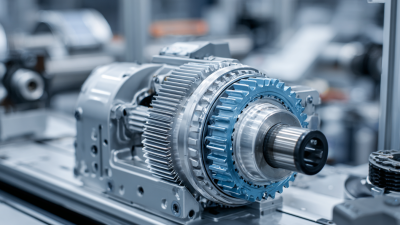

When evaluating torque requirements for your specific project, the first step is to understand the task that the motor needs to perform. This involves assessing the load conditions, including the weight of the components being moved and the type of motion required—whether it is constant, variable, or involves rapid starts and stops. By calculating the total torque needed to overcome inertia and friction, you can identify the baseline torque that your motor must provide to ensure efficient operation.

Another crucial aspect is to consider the operational environment of the application. Factors such as temperature, humidity, and potential physical obstructions can influence motor performance. High torque applications often face varying conditions, so ensuring that the motor can deliver consistent performance under these variables is essential. Additionally, any safety margins should be taken into account to prevent motor strain and to accommodate unforeseen load increases during operation. By thoroughly evaluating these factors, you can better select a high torque BLDC motor that aligns with the specific demands of your project.

When selecting a high torque Brushless DC (BLDC) motor for your project, it's crucial to compare various motor types based on performance metrics such as efficiency, torque density, and thermal management. BLDC motors are known for their high efficiency, often exceeding 90%, which is significantly higher than that of brushed motors. This efficiency is crucial for applications where power conservation is essential, such as electric vehicles and robotics. According to industry reports, the global market for BLDC motors is expected to grow at a CAGR of over 9% from 2021 to 2026, driven by their superior performance characteristics and increasing adoption in various sectors.

One of the key performance indicators in selecting a BLDC motor is torque density, which refers to the amount of torque produced per unit of motor volume. High torque density motors enable more compact designs and can contribute to reducing the overall weight of the application. Research shows that certain configurations of BLDC motors can achieve torque densities around 3.5 Nm/L, making them suitable for demanding applications like industrial automation and aerospace. Additionally, thermal management plays a significant role, as efficient heat dissipation ensures consistent performance and longevity. Effective cooling systems can enhance motor performance and reliability by maintaining optimal operating temperatures, thus preventing overheating during high-load conditions.

As you evaluate different types of BLDC motors, it is important to consider these performance metrics to ensure that the selected motor aligns with your project requirements. The integration of simulation tools and motor performance data can greatly assist in making an informed decision, ensuring a successful outcome for your application.

When sourcing a high torque BLDC motor for your project, the first step is to clearly define your project's requirements. Consider factors such as the desired torque output, speed range, and application environment. A detailed specification will help you narrow down your options and identify motors that can meet your performance criteria. It’s also helpful to assess the compatibility of the motor with existing systems and components to ensure seamless integration.

Budgeting is another critical aspect of selecting the right BLDC motor. Begin by determining the overall budget for the motor and related components. It's essential to account for not just the initial purchase price, but also potential costs related to installation, maintenance, and any additional accessories that may be required. Researching multiple suppliers can provide insight into price variations and help you find the best deal without compromising quality. Additionally, considering the long-term operational costs, such as efficiency and longevity, will aid in making a more financially sound decision in the long run.

This chart illustrates the torque performance of different high torque BLDC motors. It highlights the torque values (in Nm) for each motor model, aiding in the selection process based on project requirements.