In today's fast-paced technological landscape, the demand for efficient and versatile components is ever-increasing, particularly in the realm of Compact DC Motors. According to a recent report by Allied Market Research, the global DC motor market was valued at approximately $22 billion in 2020 and is projected to reach around $35 billion by 2028, growing at a CAGR of 6.8%. This surge in growth underscores the significance of selecting the right motor for various applications, including robotics, automotive systems, and consumer electronics. Compact DC Motors not only offer higher efficiency but also facilitate designs that require a smaller footprint without compromising performance. As engineers and designers embark on their next projects, understanding the essential factors in selecting these motors becomes imperative to ensure reliability and optimize performance. This blog will explore five critical tips to guide you in choosing the best Compact DC Motors for your specific needs.

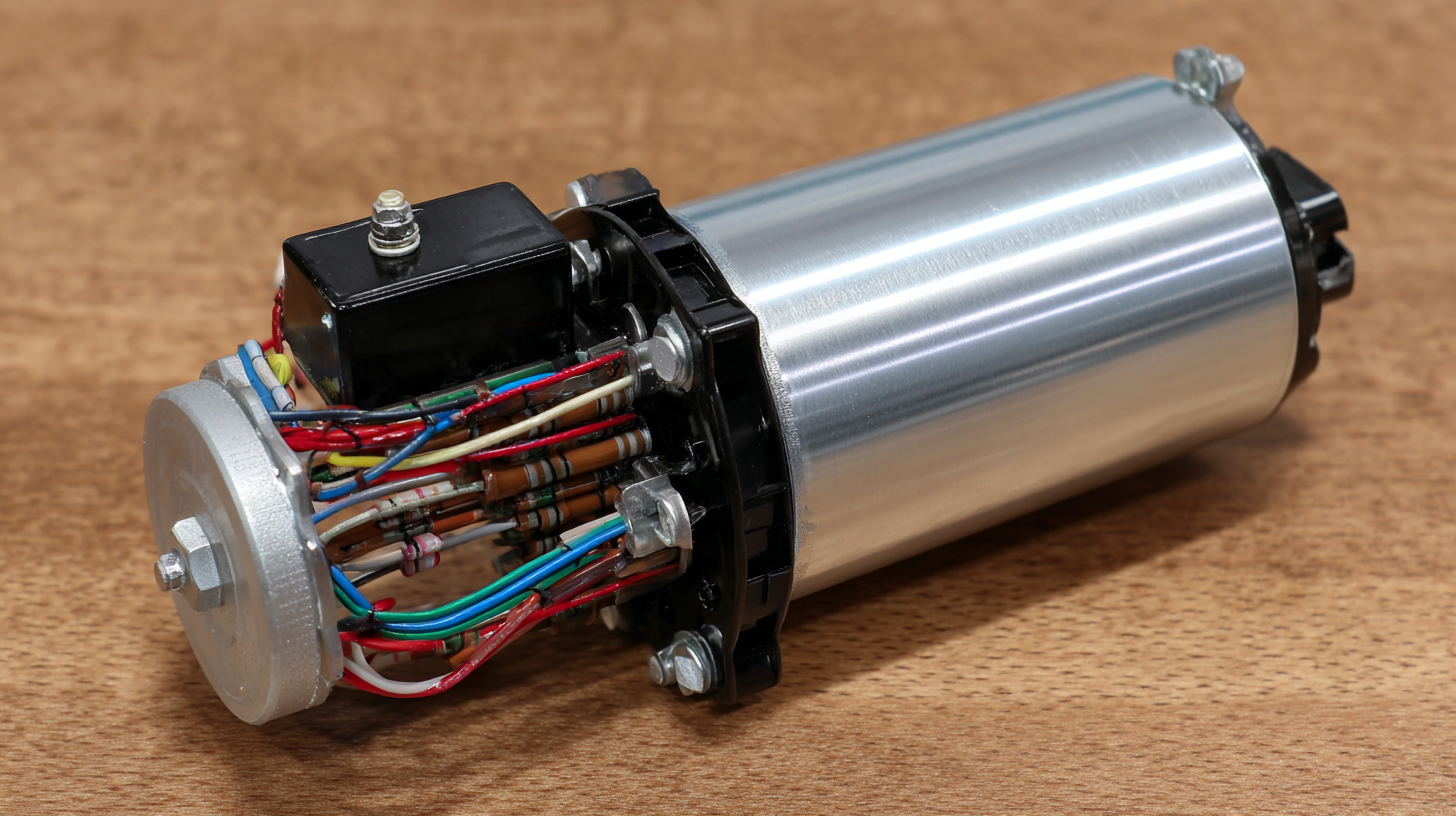

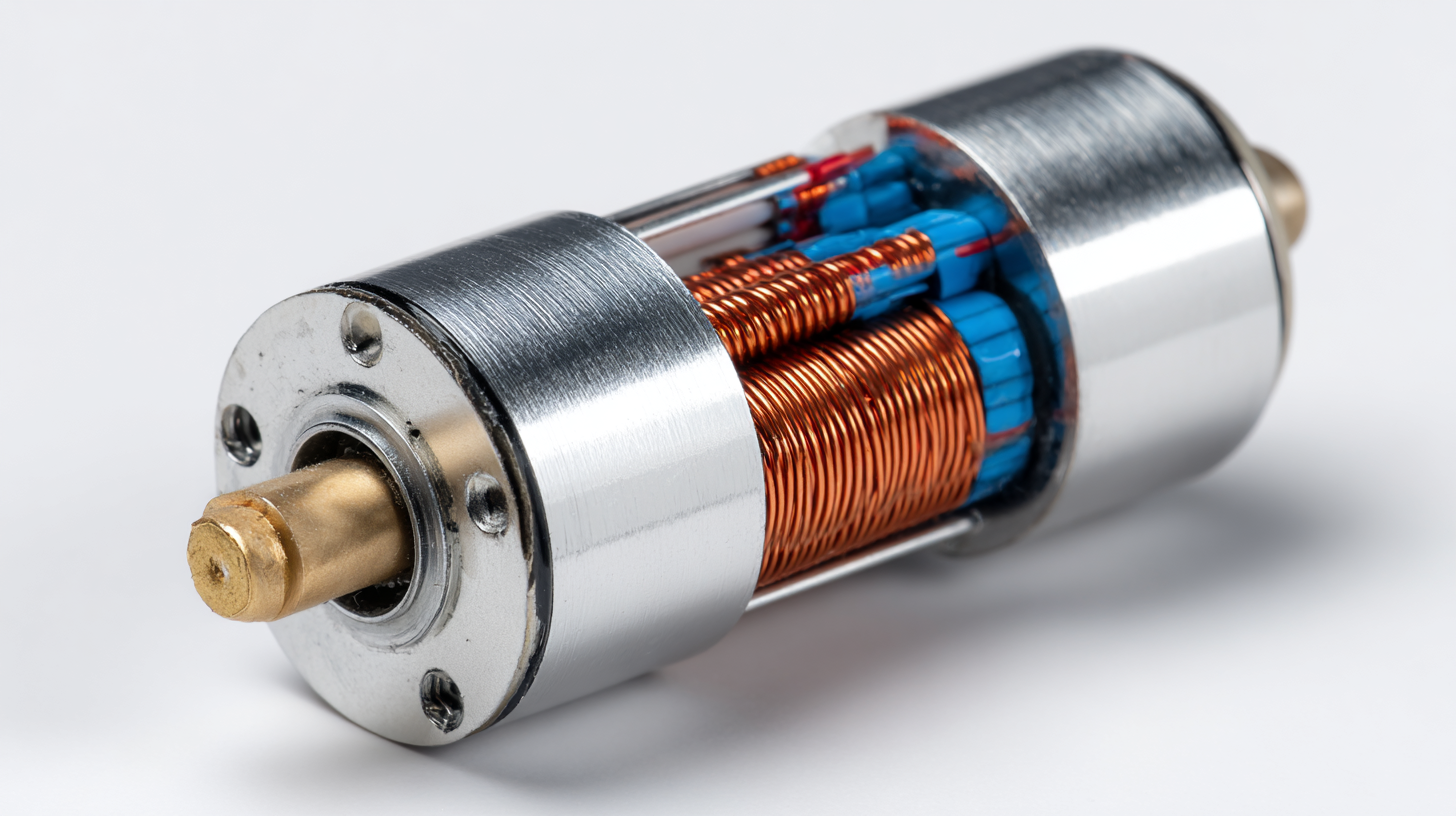

When embarking on a project that requires compact DC motors, it's crucial to grasp the variety of options available. Broadly, compact DC motors come in brush and brushless types, each presenting unique advantages. Brush DC motors are favored for their simplicity and ease of control, making them ideal for applications requiring straightforward speed regulation. Conversely, brushless DC motors offer higher efficiency and longevity, making them suitable for more demanding environments, such as robotics or drones, where power and reliability are critical.

Additionally, sizes and torque ratings are essential factors to consider when selecting a motor for your specific needs. Compact motors are designed to fit in tight spaces, but choosing the right combination of size, torque, and speed is vital for optimal performance. Always review the motor's specifications against your project's requirements to ensure you make an informed decision. Understanding these distinctions will enable you to select the suitable motor type that seamlessly integrates into your design and enhances its functionality.

When selecting compact DC motors for your next project, understanding key specifications is crucial to ensure optimal performance. First and foremost, consider the motor's voltage and current ratings. According to recent industry reports, motors with a voltage range of 6V to 24V are popular in compact applications due to their versatility and efficiency. Additionally, the current rating will dictate the power output and thermal performance, making it critical to match it with your project’s requirements.

Another significant specification is torque and speed characteristics. For instance, in humanoid robotics, actuators—that is, compact DC motors—need to provide precise control over movement. It has been noted that torque values can vary widely, but motors offering a torque range of 0.5 to 2 Nm are often suitable for achieving realistic motion. Furthermore, evaluating the motor's efficiency and noise levels is essential, especially in applications like industrial automation, where performance consistency and auditory disruption can impact overall system effectiveness. With motors being integral to automation processes, focusing on these specifications will lead to better decision-making for your projects.

When selecting a compact DC motor for your project, understanding the torque and speed requirements is crucial. Torque, measured in Newton-meters (Nm), indicates the rotational force the motor must provide. Applications may vary extensively: for instance, a robotic arm might require a peak torque of around 1.5 Nm, while small drone motors typically need about 0.1–0.5 Nm. According to a recent industry report by the International Journal of Robotics Research, efficient torque performance can significantly enhance a robot's operational capabilities and battery life.

Speed, on the other hand, is expressed in revolutions per minute (RPM) and dictates how quickly the motor can perform its tasks. For most applications, such as in automated conveyor systems, a speed range of 50 to 1000 RPM is common. In critical applications like medical devices, the required speeds might be lower but must remain consistent to ensure precise functionality. A report from the IEEE Transactions on Industrial Electronics suggests that accurately calculating both torque and speed requirements can lead to a 15% increase in efficiency across various applications, underscoring the importance of these parameters in motor selection.

When selecting compact DC motors for your next project, evaluating their efficiency and power consumption is crucial. Efficiency is a measure of how well a motor converts electrical energy into mechanical energy. High-efficiency motors can reduce power usage, ultimately leading to cost savings and better performance in your application. Consider looking for motors with efficiencies above 85%, as this typically translates into less heat generation and longer operational life.

Power consumption is another key factor to examine closely. It's important to analyze the motor's rated current and voltage to ensure that it meets your project's energy requirements without excessive draw. Additionally, consider the motor's operating conditions, such as load and speed, as these can significantly influence its power consumption. By selecting a motor that balances both efficiency and power needs, you can ensure reliable operation while minimizing energy costs, making it a wise choice for various applications ranging from robotics to small appliances.

| Motor Type | Voltage (V) | Power (W) | Efficiency (%) | No-load Current (A) | Torque (Nm) |

|---|---|---|---|---|---|

| Permanent Magnet Motor | 12 | 20 | 85 | 0.5 | 0.1 |

| Brushless DC Motor | 24 | 50 | 90 | 0.3 | 0.3 |

| Coreless DC Motor | 6 | 10 | 80 | 0.4 | 0.05 |

| Planetary Gear Motor | 12 | 30 | 82 | 0.2 | 0.2 |

| Standard DC Motor | 9 | 15 | 75 | 0.6 | 0.1 |

When embarking on a project that requires compact DC motors, budgeting and sourcing effectively can make a substantial difference in your project's success. According to the market analysis by Research and Markets, the global DC motor market is projected to grow at a CAGR of 5.5% from 2022 to 2028. This growth signifies an increasing competition among suppliers, which can ultimately benefit project developers in terms of cost and availability.

One essential tip for budgeting is to start by understanding the specific motor requirements of your project. Look for options that balance performance with budget constraints. For instance, consider the motor’s voltage, torque, and speed specifications to avoid overspending on unnecessary features. Additionally, websites like Alibaba and ThomasNet can help source competitive quotes from multiple suppliers, ensuring you get the best possible deal.

Another critical aspect is to keep an eye on seasonal sales and bulk purchase discounts. Manufacturers often provide better pricing when you order in larger quantities or during promotional periods. Research shows that purchasing during off-peak seasons could save you up to 20% on costs, making it an optimal time to stock up on the components you need. By strategically navigating these elements, you can effectively manage your budget while securing reliable compact DC motors for your next project.