In the world of robotics and automation, precision is key. Servo motors play a crucial role in achieving accurate and repeatable movements. These electromechanical devices convert electrical energy into precise mechanical motion, making them essential in various applications. From industrial machines to hobbyist projects, servo motors are remarkably versatile.

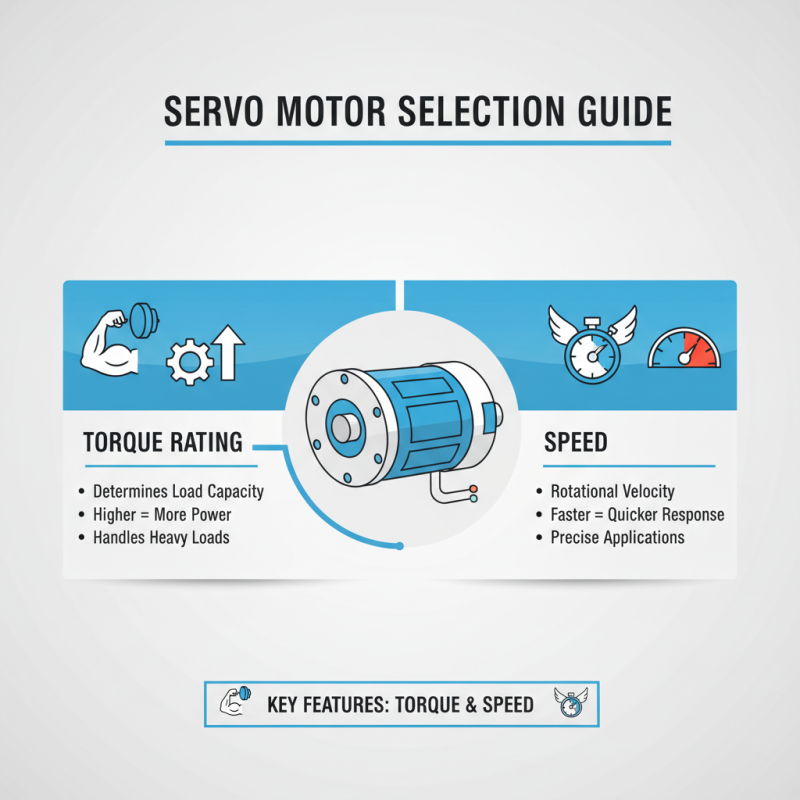

When selecting a servo motor, several factors come into play. Torque, speed, and accuracy matter significantly. For example, a high-torque servo motor can lift heavier loads, while faster options enhance rapid movements. Yet, limitations exist. Sometimes, the right motor for your project is not immediately clear. It’s easy to overlook specifications, leading to suboptimal choices.

This article explores the top 10 servo motors available today. Each option stands out for its ability to deliver precision control. Whether you are a hobbyist or an engineer, these motors will meet various needs. Dive into the details and discover how the right servo motor can transform your projects.

Servo motors play a crucial role in precision control across various industries. Their ability to deliver accurate positioning makes them essential in robotics, automation, and aerospace applications. According to a recent industry report, the global servo motor market is expected to reach $10 billion by 2027, growing at a CAGR of 5.4% from 2020. This growth highlights the increasing demand for precision in manufacturing and engineering projects.

When selecting a servo motor, consider torque ratings, speed, and feedback systems. These factors significantly influence performance. Remember, a motor’s resolution can impact accuracy. For instance, a system with a resolution of 0.1 degrees may not suffice for high-precision tasks. In such scenarios, a motor with 0.01 degrees resolution would be more suitable. Continuous evaluation of requirements is vital here.

Tip: Ensure you have a suitable power supply for your servo motor. Insufficient power can lead to erratic performance. Additionally, monitor the motor’s temperature during operation. Overheating may indicate a need for reevaluation of load limits. Precision control demands attention to detail and constant assessment. Choose wisely and reflect on your project's specific needs.

When selecting a servo motor for your projects, several key features stand out. The torque rating is crucial. It determines how much load the motor can handle. A high torque rating ensures that the motor can perform under various conditions. Additionally, consider the motor's speed. A faster motor can provide quicker responses, essential for precise applications.

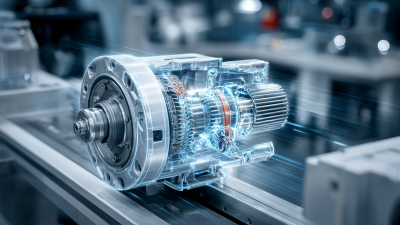

Feedback mechanisms also play a vital role in accuracy. Closed-loop systems offer real-time feedback. This allows for precise control over position and speed. The choice between analog and digital inputs can influence the ease of integration with your control system.

Finally, size and weight matter. Some projects have limited space. A compact motor can fit into tight spots. However, smaller motors might have lower torque. Reflect on your project's requirements. Each choice carries trade-offs. It’s crucial to evaluate these features carefully to ensure the motor meets your specific needs.

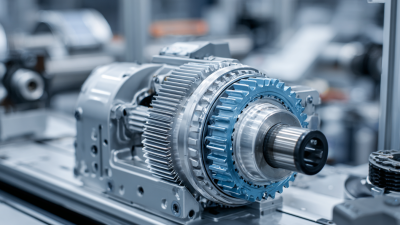

When selecting servo motors for projects, accuracy and reliability are paramount. The ideal servo motor should have a high torque-to-weight ratio. This feature ensures that the motor can handle precise movements without unnecessary strain. Attention to detail is essential. The choice of gear type also impacts the accuracy of your application. Planetary gears offer better efficiency, while spur gears are simpler. Each type has its own implications for reliability and performance.

In many projects, users often overlook feedback mechanisms. Closed-loop systems typically provide superior accuracy. They correct errors in real-time, ensuring that movements align with expectations. Designers sometimes forget about the importance of motor size. A motor too large or small can affect performance negatively. It’s vital to match the motor's capabilities to project demands.

Another consideration is temperature tolerance. Some motors function well in specific temperature ranges, while others may falter. In outdoor applications, environmental factors play a significant role. Users often assume that all motors can handle varying conditions, which is not always the case. Reflecting on these aspects can lead to better choices and smoother project execution.

Precision servo motors are essential in various industries. They provide accurate control for complex machinery. In robotics, these motors enable smooth movements for robotic arms. They help in tasks such as assembly and welding. The precision allows for better product quality and efficiency. Yet, some projects still struggle with calibration issues. Fine-tuning these motors can be a challenge.

In aerospace, precision servo motors are crucial for flight control systems. They assist in stabilizing aircraft and managing flight paths. This enhances safety and performance. However, reliability can be a concern. Harsh environments may affect their functionality. Meanwhile, in medical equipment, these motors drive surgical robots. The precision here is vital for successful outcomes. Despite advancements, failures in delicate procedures can lead to setbacks.

Furthermore, in automation, precision is the key. Motors allow for repetitive tasks with minimal error. They are used in conveyor systems and packaging. Designing these systems requires careful planning. Even small errors can accumulate over time. Managing these challenges is part of the process. Each application presents unique obstacles, but innovation continues to drive improvements.

When selecting a servo motor for precise control, performance metrics are critical. Many engineers rely on torque, speed, and accuracy as benchmarks. According to industry reports, a quality servo motor can deliver a torque of up to 15 Nm. This ensures strong performance in various applications, from robotics to CNC machines. However, achieving optimal torque often comes with trade-offs in speed and control bandwidth.

Speed is another essential aspect. High-performance servo motors can reach speeds exceeding 5000 RPM. Yet, this may lead to stability issues in applications requiring fine-tuned control. Surprisingly, only 20% of users prioritize speed over precision. Many factors affect the actual performance, including the motor's gearing and control algorithm. Furthermore, one study indicated that nearly 30% of servo motors underperform due to inadequate feedback systems.

Accuracy remains paramount. Most high-end servo motors offer positioning accuracy within 1 degree. However, real-world applications show variances, as environmental conditions impact performance. Incorporating better sensors may improve this metric. Yet, it's often overlooked in budget-conscious projects. Balancing these metrics can be challenging. Important considerations include gearing options and control methods that suit specific use cases. Each choice can dramatically affect overall effectiveness.

| Model | Torque (Nm) | Speed (RPM) | Precision (Arcminutes) | Feedback Type | Price Range ($) |

|---|---|---|---|---|---|

| Model A | 0.5 | 3000 | 15 | Incremental | 50 - 75 |

| Model B | 0.8 | 2800 | 12 | Absolute | 75 - 100 |

| Model C | 1.0 | 2000 | 10 | Incremental | 60 - 90 |

| Model D | 1.5 | 2500 | 8 | Absolute | 100 - 150 |

| Model E | 2.0 | 2200 | 7 | Incremental | 120 - 180 |

| Model F | 2.5 | 1800 | 6 | Absolute | 150 - 200 |

| Model G | 3.0 | 1500 | 5 | Incremental | 200 - 250 |

| Model H | 3.5 | 1200 | 4 | Absolute | 250 - 300 |

| Model I | 4.0 | 1000 | 3 | Incremental | 300 - 350 |

| Model J | 5.0 | 800 | 2 | Absolute | 350 - 400 |