Choosing the right industrial BLDC motor can be challenging. According to John Smith, an expert in electric motor technology, "Selecting the proper motor is vital for operational efficiency." Understanding various factors is crucial to making an informed decision.

Industrial BLDC motors are utilized in numerous applications, from robotics to HVAC systems. Key considerations include efficiency, torque, and compatibility with existing systems. Often, users neglect the importance of matching motor specifications to their unique requirements. The wrong choice can lead to performance issues and increased costs.

Cost should not be the only focus. Quality and reliability are equally essential. Many buyers overlook these aspects, leading to regret down the line. Taking the time to thoroughly evaluate each option can save significant trouble in the future.

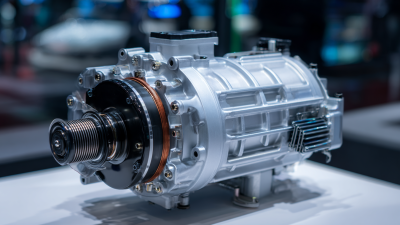

Understanding industrial BLDC (Brushless DC) motors is key for selecting the right one for your application. These motors operate efficiently, with typical efficiencies ranging from 85% to over 90%. This is crucial in industries aiming to reduce energy costs. The design of BLDC motors minimizes energy loss, leading to longer service life and lower maintenance.

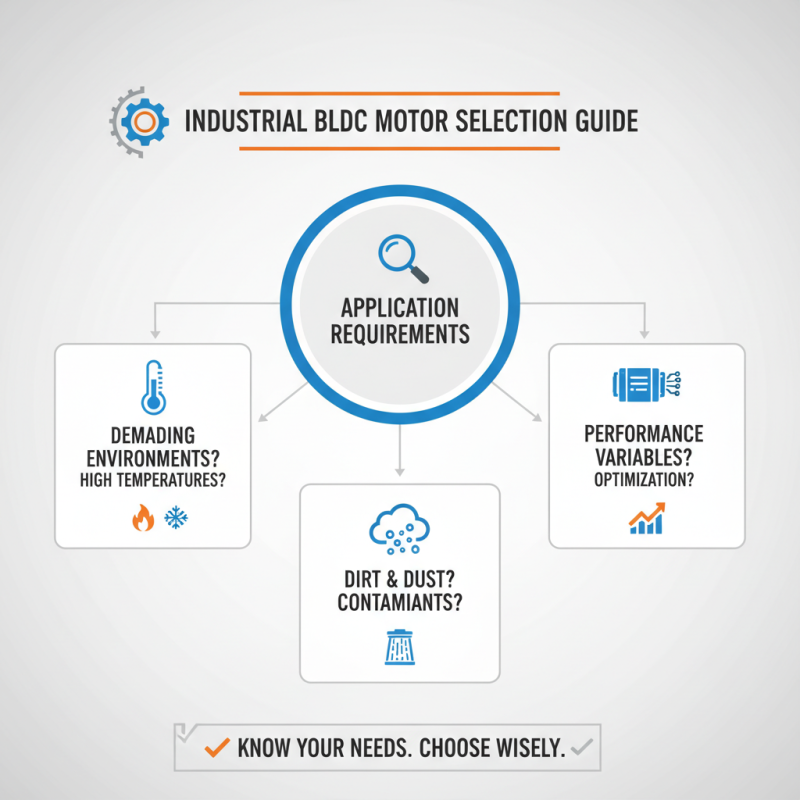

When choosing a BLDC motor, consider torque and speed requirements. For instance, applications that need precise control often benefit from high-torque motors. It’s also important to evaluate the environmental conditions where the motor will operate. Factors like temperature and humidity can affect performance and durability. Industry reports indicate that improper conditions can lead to up to 30% more wear on mechanical components.

Additionally, look into the control systems. The integration of sensors can enhance motor performance but may add to complexity. A lack of understanding here could result in inefficiencies. Sometimes, a simpler system could be more reliable, reinforcing the importance of matching the motor's capabilities with the application requirements. Balancing these aspects can significantly impact productivity and operational costs.

When selecting the right industrial BLDC motor, understanding your application requirements is crucial. This process begins with a careful evaluation of the motor's intended use. Are you dealing with demanding environments? High temperatures or dust might affect performance. Knowing these variables helps narrow down options significantly.

Torque and speed requirements are other essential factors to consider. Different applications require varying torque levels. For instance, a conveyor belt may need high torque at low speeds. On the contrary, a fan might prioritize high-speed operation. Aligning the motor specifications with application needs is vital. However, balancing these can be tricky. Too much torque might lead to inefficiency, while too little could hinder performance.

Don't forget about the power source. Consider how much energy the operation will consume. Think about conservation and efficiency as well. Matching voltage and phase requirements should not be overlooked. Sometimes, the perfect motor isn't apparent at first glance. Engaging in reflection about your choices can uncover better paths. This might lead to insights you hadn't considered.

When selecting a brushless DC (BLDC) motor, several key features deserve your attention. The motor’s efficiency is crucial, as it directly affects performance and energy consumption. Look for motors that provide high torque density while minimizing losses during operation. Understanding the efficiency rating can help you gauge its potential effectiveness in your application.

Another important aspect is speed control. Many applications require precise speed adjustments. Ensure the motor supports various control modes, like PID or PWM. It’s essential to analyze the motor's responsiveness to ensure it meets your specific operational requirements. Also, pay attention to the noise levels, as some applications require quieter operations.

Don’t forget about size and weight limitations. A compact design might be necessary for some installations, but smaller motors can sometimes sacrifice power. Strike a balance between power output and physical dimensions. Lastly, consider the cooling mechanisms. Proper heat management is vital for longevity and stable performance. This can prevent overheating and ensure reliability in demanding environments.

When choosing the right industrial BLDC motor, understanding the types and specifications is crucial. There are three main types: inner rotor, outer rotor, and disc motors. Each type has distinct characteristics that affect performance. For instance, inner rotor motors often provide higher speeds and torque, making them suitable for applications needing quick acceleration. In contrast, outer rotor designs excel in applications where efficiency is a priority, operating cooler and quieter.

Specifications such as commutation methods and efficiency ratings play a vital role in selecting the appropriate motor. According to industry reports, efficiency can vary widely, with some high-performance models reaching over 90%. This is significant when energy costs account for a substantial portion of operational expenses. Additionally, the torque-to-weight ratio is a crucial factor; a higher ratio generally indicates better performance in compact designs. However, achieving optimal torque can lead to trade-offs in size and weight that are worth considering.

Overall, understanding these nuances can navigate the complexities of BLDC motor selection. While one might focus solely on power output or cost, overlooking crucial specs like thermal management or noise levels can lead to operational inefficiencies. Balancing these factors requires careful thought and analysis.

When budgeting for an industrial BLDC motor, precise planning is crucial.

Determine your total budget before sourcing.

Consider all costs, including installation and maintenance.

This foresight helps avoid overspending later.

Even small expenses can add up quickly.

One tip is to compare prices from different suppliers.

Take time to research various manufacturers.

Look for hidden costs in quotes.

This transparency can save you money.

Also, consider the total cost of ownership.

Cheaper motors might lead to higher energy bills over time.

Another point is to examine the specifications carefully.

Don't just focus on price; performance matters too.

A low upfront cost might mean poorer efficiency or shorter lifespan.

Always ask for performance data to make informed decisions.

Ignoring these details can lead to regrets later.