The evolution of brushless direct current (Bldc) servo systems has marked a significant milestone in the realm of automation and control technologies. These advanced systems are recognized for their exceptional performance, reliability, and efficiency, making them an ideal choice for a wide range of industrial applications. With the capacity to provide precise motion control and high responsiveness, Bldc servo systems are increasingly being employed in robotics, aerospace, and manufacturing sectors, enhancing both productivity and operational efficiency.

Understanding the underlying principles and components of Bldc servo systems is crucial for engineers and designers aiming to leverage these technologies effectively. These systems operate on the fundamental concepts of electromagnetic principles, utilizing advanced control algorithms to optimize motor performance. By addressing key parameters such as torque, speed, and positional accuracy, Bldc servo systems enable enhanced control capabilities, thus accommodating the demands of modern automation processes. This introduction aims to provide an overview of Bldc servo technology, emphasizing its advantages and potential applications in various fields, ultimately showcasing how these systems contribute to improved performance and operational efficiency.

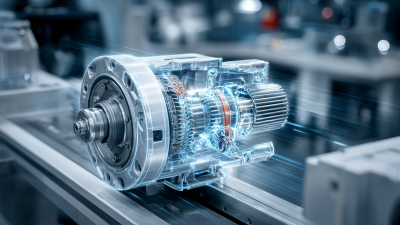

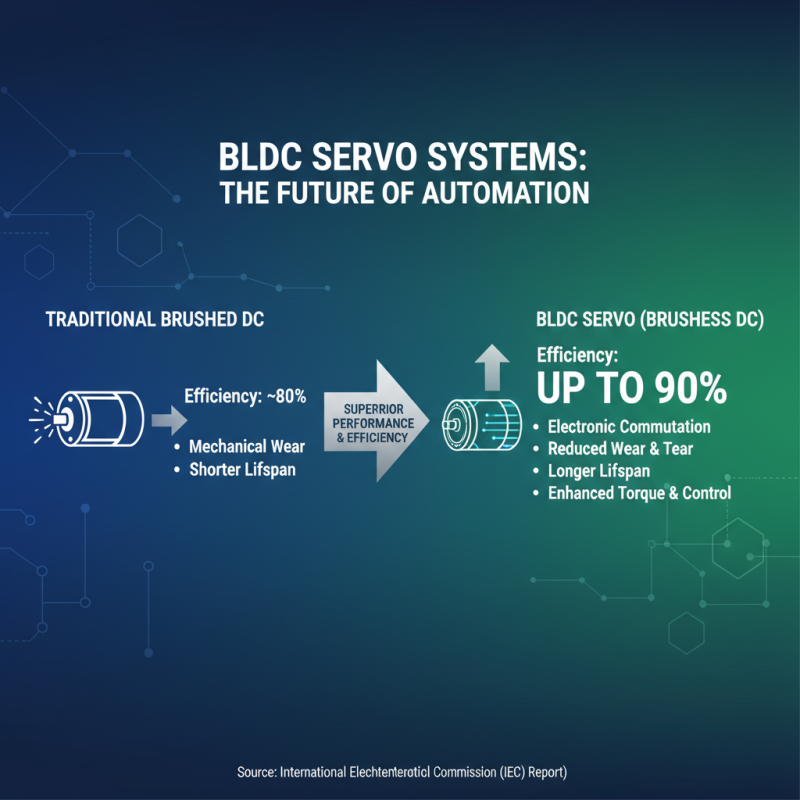

BLDC (Brushless DC) servo systems are at the forefront of modern automation and robotics, offering superior performance and efficiency compared to traditional servo motors. These systems rely on electronic commutation instead of mechanical brushes, resulting in reduced wear and longer lifespans. A key component of BLDC servo systems is the rotor, which is typically designed with permanent magnets. This configuration allows for enhanced torque output and better speed control. According to a recent report by the International Electrotechnical Commission (IEC), the efficiency of BLDC motors can reach up to 90%, significantly outperforming brushed counterparts, which often max out around 80% efficiency.

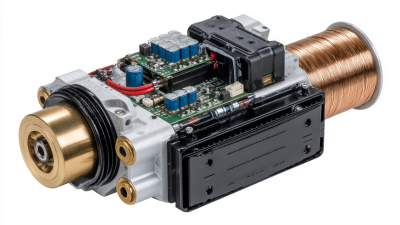

Another critical component is the controller, which utilizes sophisticated algorithms to optimize the performance of the motor based on real-time feedback. This controller adjusts the voltage and current supplied to the motor, ensuring that it operates within its optimal range. With advancements in digital signal processing (DSP), these controllers can respond to changes in load and speed almost instantaneously. A study published by the Institute of Electrical and Electronics Engineers (IEEE) indicates that precise control can lead to a 20% increase in energy efficiency, making BLDC servo systems a preferred choice in applications that require high reliability and performance, such as aerospace and industrial automation.

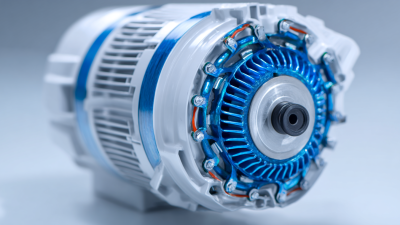

Brushless DC (BLDC) servo motors have become integral in various applications due to their superior performance and efficiency. The principle of operation relies on the interaction between the magnetic field produced by the stator and the rotor, which often contains permanent magnets. As an electric current flows through the windings of the stator, it generates a rotating magnetic field. This field induces torque in the rotor, causing it to spin. The speed and position of the motor can be precisely controlled by varying the supply of current through sensors or advanced control algorithms, making BLDC motors ideal for high-performance applications.

Tips: When designing systems using BLDC servo motors, consider selecting a suitable controller that can handle the motor’s specific requirements. Ensure the controller includes feedback mechanisms such as encoders for precise control. Also, thermal management is crucial; ensure there is adequate cooling to maintain efficiency and avoid overheating.

Another significant aspect of BLDC servo motors is their efficiency compared to their brushed counterparts. The absence of brushes reduces wear and energy losses, resulting in longer operational life and lower maintenance costs. Additionally, regenerative braking capabilities allow these motors to return energy to the power source during deceleration, enhancing overall system efficiency.

Tips: Be mindful of the power supply specifications to avoid voltage spikes, which can lead to motor failure. Furthermore, implementing robust programming practices for motor control will optimize performance and reduce downtime.

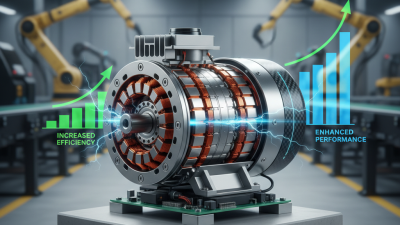

This chart illustrates the performance metrics of Brushless DC (BLDC) Servo Motors, showcasing key parameters such as torque, speed, efficiency, and response time. These dimensions provide insights into the operational advantages offered by BLDC systems for enhanced performance and efficiency.

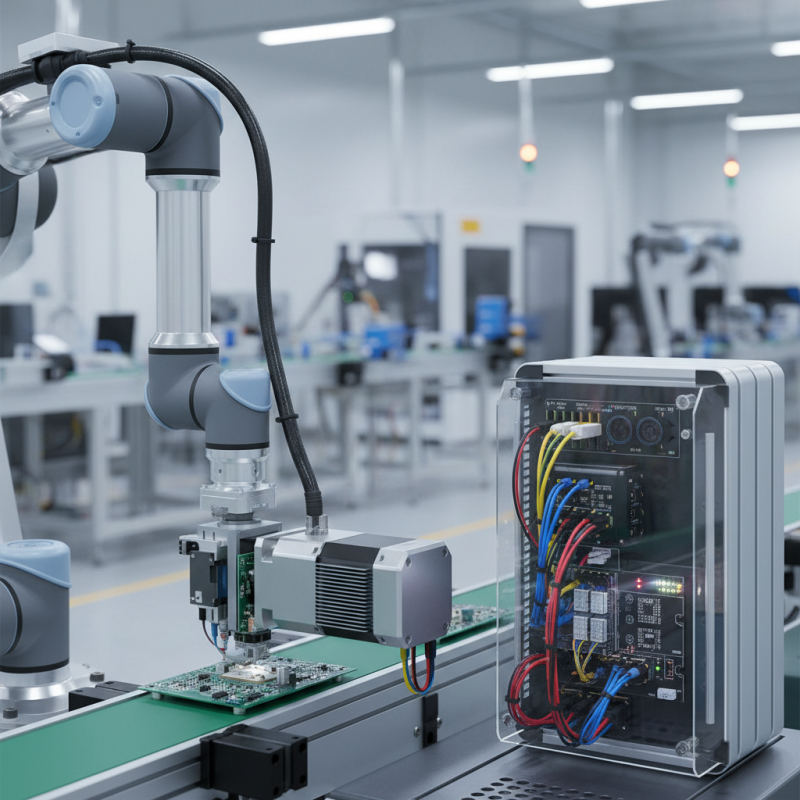

BLDC (Brushless DC) servo systems are revolutionizing industrial applications by providing enhanced performance and efficiency. These systems are known for their high torque-to-weight ratio, which allows for quicker acceleration and deceleration. According to a recent report by Research and Markets, the global BLDC motor market is projected to grow at a CAGR of 14.2% from 2021 to 2026, illustrating the increasing reliance on this technology in various sectors such as robotics, automotive, and manufacturing.

One of the primary advantages of BLDC servo systems is their energy efficiency. Traditional DC motors can have significant energy losses due to friction and heat, whereas BLDC motors minimize these losses, contributing to reduced operational costs. Additionally, these systems provide precise control of speed and position, which is crucial in applications requiring high accuracy, such as CNC machines and robotic arms. A study by the Electric Power Research Institute highlights that implementing BLDC motors can lead to energy savings of up to 30%, making them a sustainable choice for companies aiming to lower their carbon footprint.

Tip: When considering BLDC servo systems for your industrial application, look for systems that offer integrated feedback mechanisms. This can significantly enhance precision and responsiveness, reducing the risk of errors in critical processes. Another valuable tip is to conduct a lifecycle cost analysis to better understand the long-term benefits of transitioning to BLDC systems compared to traditional motors.

When considering the performance and efficiency of BLDC (Brushless DC) servo systems, several key factors play a critical role. One of the most important is the control strategy employed. A well-optimized control algorithm can significantly enhance the responsiveness and precision of the system, allowing for smoother operation and better energy management. For instance, field-oriented control (FOC) is often favored for its ability to provide superior torque response and efficiency by aligning the torque and magnetic fields.

Another vital factor is the quality of the components used in the system. High-performance sensors, durable bearings, and robust power electronics contribute immensely to the system's reliability and longevity. Choosing components that minimize friction and energy loss can lead to enhanced overall efficiency.

**Tips:** When selecting components, aim for those that offer low resistance and high thermal stability to reduce energy waste. Regular maintenance also ensures that all parts are functioning optimally, thus prolonging the system's life and efficiency.

Lastly, the integration of feedback mechanisms plays a pivotal role in optimizing performance. By utilizing encoders or other sensors, the system can dynamically adjust its operations to maintain optimal performance under varying loads and speeds. This real-time adaptability not only improves efficiency but also ensures consistent performance across diverse applications.

**Tips:** Implementing advanced feedback systems can help in early detection of inefficiencies, allowing for timely adjustments before they escalate into larger issues.

| Factor | Description | Impact on Performance | Impact on Efficiency |

|---|---|---|---|

| Motor Design | Factors such as rotor structure and winding configuration. | Affects torque generation and speed response. | Efficient designs reduce energy losses. |

| Controller Algorithm | Type of control strategy used (e.g., PID, FOC). | Improves responsiveness and positional accuracy. | Higher efficiency through optimized control. |

| Feedback System | Sensors used for feedback (e.g., encoders, resolvers). | Enhances accuracy in position and speed control. | Improves overall system efficiency through precise control. |

| Power Supply | Quality and stability of the voltage supplied. | Directly impacts motor performance under load. | Stable supply enhances energy usage efficiency. |

| Thermal Management | Methods used to dissipate heat (e.g., heatsinks, fans). | Prevents overheating and maintains performance levels. | Effective thermal management preserves efficiency. |

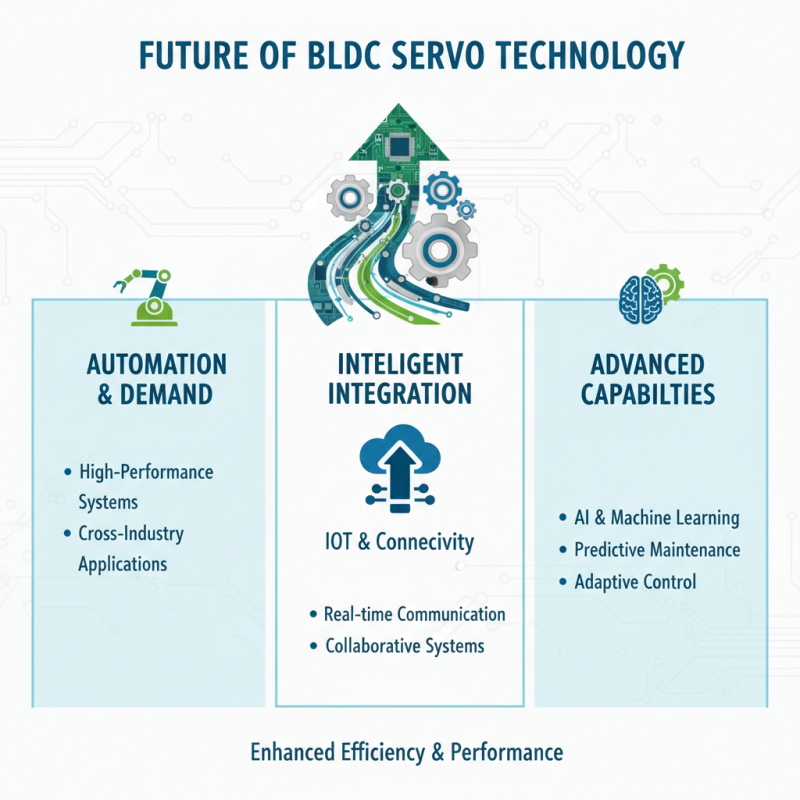

The future of BLDC (Brushless Direct Current) servo technology is shaped by advancements in automation and the demand for high-performance systems across various industries. Enhanced integration capabilities with IoT (Internet of Things) are paving the way for more intelligent servo systems that can communicate and collaborate in real time. These systems are expected to employ advanced algorithms and machine learning techniques, allowing for predictive maintenance and adaptive control strategies that improve overall performance and efficiency.

In addition to smart connectivity, innovations in materials and design are driving the evolution of BLDC servo systems. The development of lighter and more durable components enables better thermal management and more compact designs. Furthermore, advances in battery technology and energy harvesting techniques will significantly extend operational life and reduce downtime in applications, particularly in robotics and automation. With these innovations, BLDC servo systems are set to enhance productivity while minimizing energy consumption, establishing themselves as essential tools in the quest for sustainable and efficient industrial processes.