As the world continues to evolve with technological advancements, the role of automation in various industries is becoming increasingly prominent. Servo motors, recognized for their precision and efficiency, are at the forefront of this revolution. Industry expert Dr. Emily Carter, a leading authority in motion control systems, emphasizes the significance of servo motors in the future of automation: “The integration of servo motors into automated systems not only enhances performance but also opens the door to unprecedented levels of innovation.”

In the context of manufacturing, robotics, and other applications, servo motors provide the agility and accuracy needed to meet the demands of modern processes. With the ongoing shift toward smart factories and Industry 4.0, understanding the intricacies of servo motor technology is essential for businesses looking to stay competitive. As we delve into the top five insights regarding the future of automation with servo motors, we uncover the transformative impact these components will have on industries ranging from automotive to healthcare.

The implications of advanced servo motor technology extend beyond mere efficiency; they encompass adaptability, scalability, and enhanced productivity. As companies begin to harness these capabilities, it is clear that servo motors will play a pivotal role in shaping the landscape of automation and driving the next wave of industrial evolution.

The industrial automation landscape is undergoing a significant transformation, driven largely by the advancements in

servo motor technology. By facilitating precise control in machinery,

servo motors are playing a crucial role in enhancing productivity and operational efficiency. As per recent market reports,

the global low-voltage electric vehicle market is projected to expand from

$67.1 billion in 2025 to

$100.8 billion by 2032, indicating a robust CAGR of 7.05%.

This surge reflects an increasing reliance on automated solutions, where servo motors are integral to optimizing performance

in various applications.

The industrial automation landscape is undergoing a significant transformation, driven largely by the advancements in

servo motor technology. By facilitating precise control in machinery,

servo motors are playing a crucial role in enhancing productivity and operational efficiency. As per recent market reports,

the global low-voltage electric vehicle market is projected to expand from

$67.1 billion in 2025 to

$100.8 billion by 2032, indicating a robust CAGR of 7.05%.

This surge reflects an increasing reliance on automated solutions, where servo motors are integral to optimizing performance

in various applications.

In Germany, the energy-saving vehicle market is also set to see impressive growth, anticipated to reach substantial shares

with a CAGR of 6.1% from 2025 to 2035. This boom underscores the pivotal

function of automation, enabling manufacturers to develop innovative products while significantly cutting operational costs.

It's evident that as companies grapple with production efficiency and labor costs, technologies such as servo motors become

central to navigating these challenges.

Tips: Invest in servo motor technology that offers

scalability and flexibility

to adapt to varying production needs. Additionally, keep an eye on developments in robotics, as recent expos have

highlighted breakthrough technologies poised to revolutionize manufacturing processes, making efficient automation more

accessible than ever.

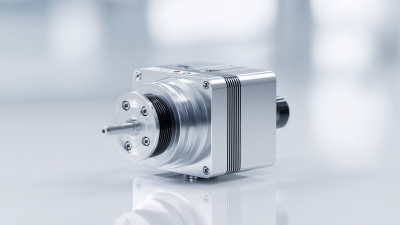

The advancements in servo motor technology are pivotal in enhancing automation efficiency across various industries. According to a recent report by Markets and Markets, the global servo motor market is projected to reach $10.4 billion by 2025, growing at a CAGR of 6.2% from 2020. This growth is largely driven by the increasing demand for process automation in manufacturing, coupled with the need for high precision and speed in operations. Modern servo motors are designed to provide greater accuracy in control systems, which facilitates smoother operations and minimizes downtime.

Furthermore, innovations such as the integration of IoT in servo motors are revolutionizing automation practices. A study from Technavio reveals that the adoption of IoT-enabled servo motors can enhance operational efficiency by up to 30%. These smart motors allow real-time data collection and monitoring, enabling predictive maintenance and reducing the risk of unexpected failures. As businesses continue to seek streamlined operations, the evolution of servo motors is set to play a crucial role in driving the next wave of automation efficiency.

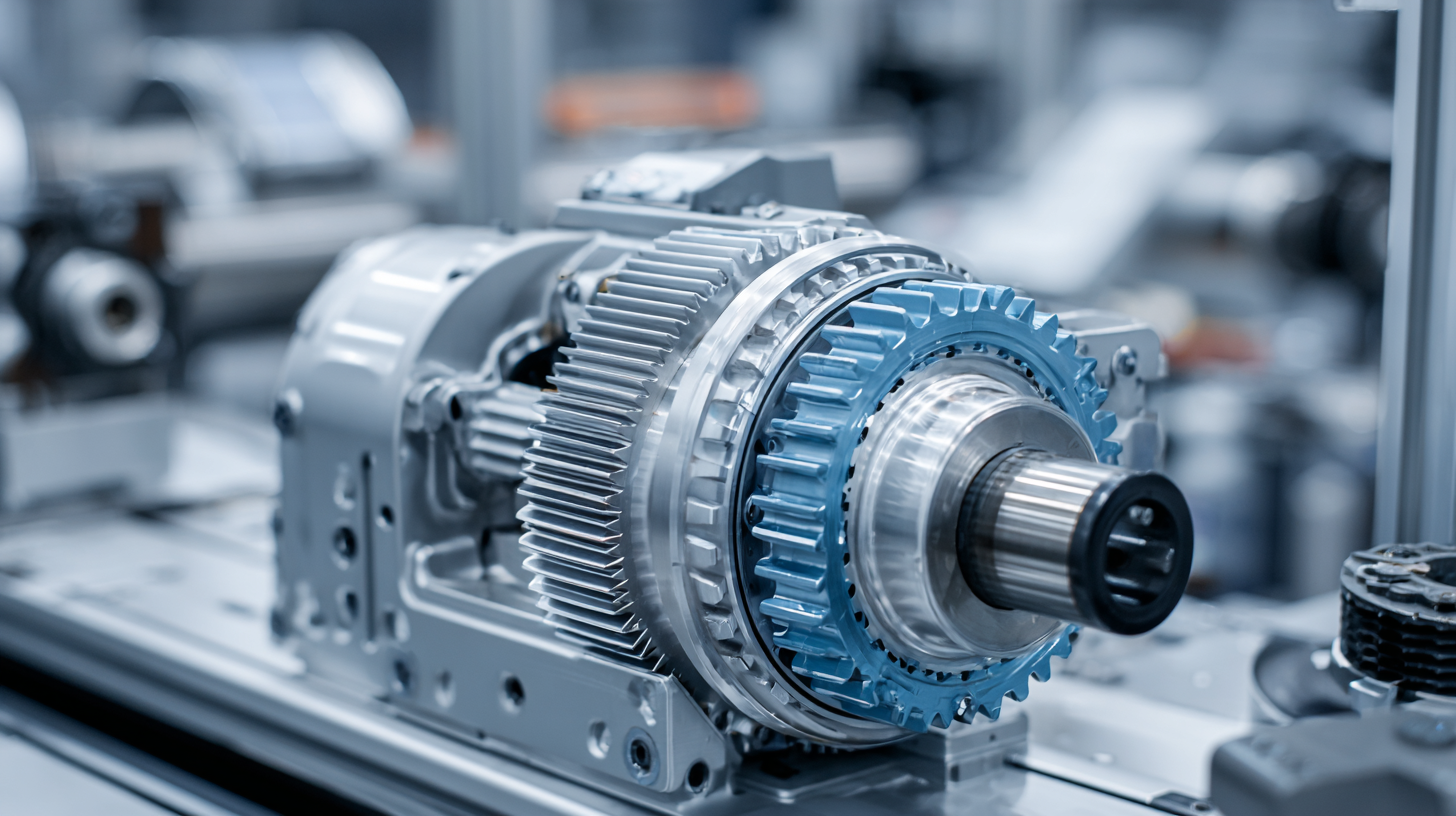

Servo motors are becoming increasingly crucial across various industries due to their precision and reliability in automation. In sectors such as manufacturing, robotics, and automotive, servo motors facilitate the accurate control of movement, enhancing productivity and efficiency. As indicated by the projected growth of the global computer vision market, expected to reach $25.41 billion in 2024 and further expand to $175.72 billion by 2032, industries are continuously integrating advanced technologies, including servo motors, to streamline operations and improve performance.

In the aerospace sector, servo motors are essential for controlling flight systems, where reliability is paramount. Similarly, in the healthcare industry, precision is vital for robotic surgical instruments, which heavily rely on servo motors to ensure careful and exact operations. Reports suggest that the market for artificial intelligence in industrial applications will grow significantly, with an expected CAGR of 32.4% from 2023 to 2030, demonstrating the increasing reliance on intelligent systems that integrate servo motor technology.

**Tip:** When choosing a servo motor for your application, consider factors such as torque requirements, speed, and control fidelity to ensure optimal performance for specific industry needs. Always refer to the latest market trends and forecasts to stay ahead in technology adoption.

This chart illustrates the application of servo motors across various industries, highlighting the importance of servo motors in modern automation technology. Manufacturing and automotive industries lead in their usage, while aerospace and healthcare also utilize these advanced technologies significantly.

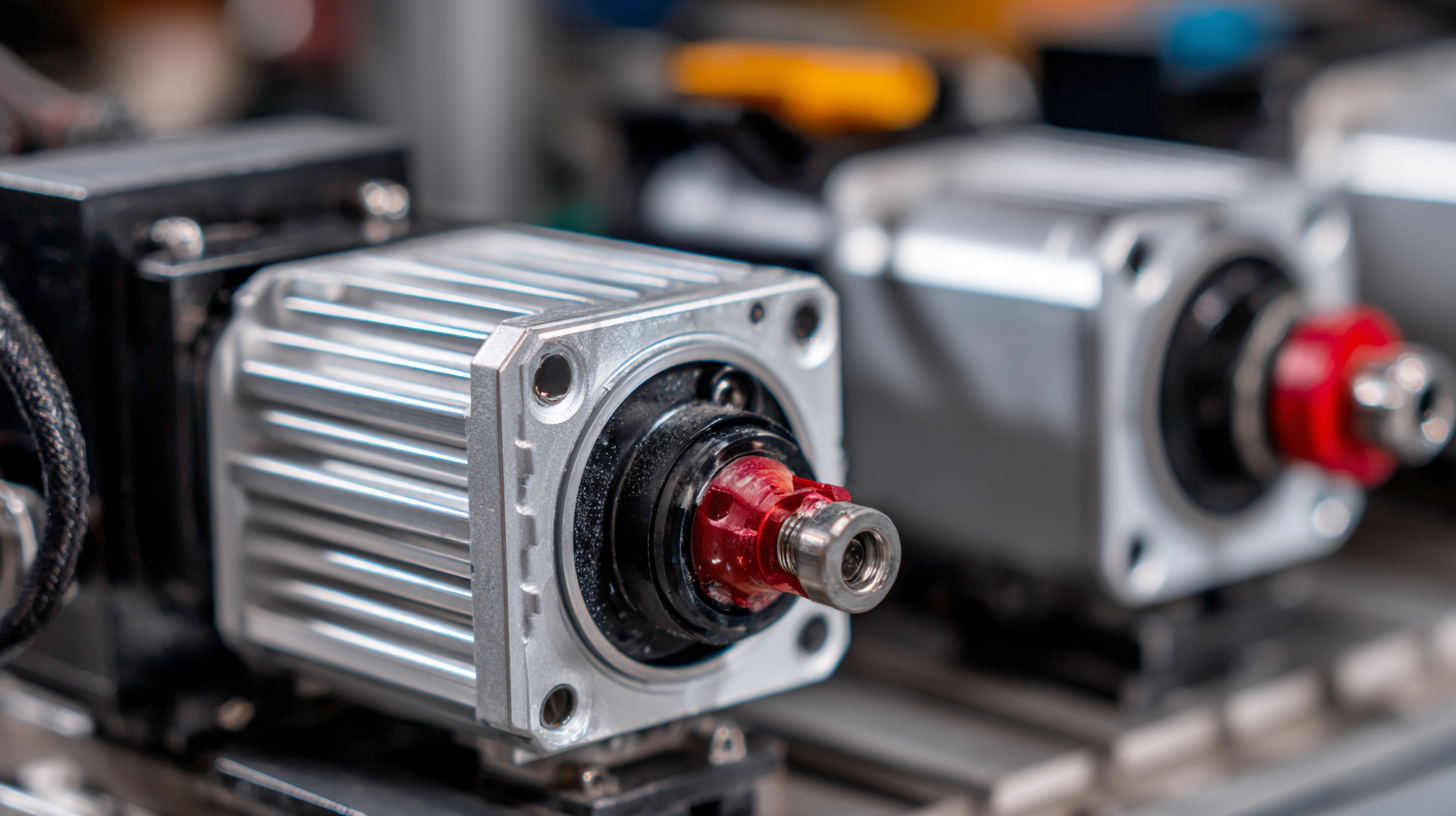

The implementation of servo motor automation presents various challenges that industries must navigate to leverage its advantages fully. One of the primary obstacles is ensuring adaptive, real-time control in environments that are highly variable and temperature-sensitive. For instance, in a manufacturing setting, variations in production demands can complicate the automation process. Companies like Rutland Plastics have faced such challenges head-on by integrating servo-based motion and programmable logic controls to enhance precision during heat-staking automation. This allows for more flexibility and efficiency, mitigating the risks associated with traditional automation methods.

Another significant challenge is the initial cost of transitioning to servo motor systems. While the global integrated servo motor market is projected to grow significantly, the investment required for upgrading existing machinery can deter some organizations. However, with the rising demand for precision in automation applications, including robotics for aquaculture and underwater inspections, the long-term benefits—such as reduced maintenance costs and improved safety—often outweigh these initial expenditures. As industries continue to embrace servo technology, finding effective solutions to these challenges will be crucial in shaping the future of automation.

| Dimension | Description | Challenges | Solutions |

|---|---|---|---|

| Cost | Initial investment in servo motor systems can be high. | Budget constraints and ROI concerns. | Phased implementation and financing options. |

| Integration | Need for compatibility with existing systems. | Technical challenges in interfacing. | Utilizing middleware and adapters for compatibility. |

| Training | Operators may need new skills to manage servo systems. | Resistance to change and learning curve. | Investing in training programs and workshops. |

| Maintenance | Servo motors require regular maintenance for optimal performance. | Downtime during maintenance and repair. | Implementing predictive maintenance and schedules. |

| Performance | Servo motors provide precise control and efficiency. | Achieving desired performance parameters can be difficult. | Optimizing settings and continual monitoring. |

The integration of artificial intelligence (AI) and machine learning into servo systems marks a significant evolution in automation technology. These advanced algorithms enable servo motors to adapt to varying operational conditions and optimize their performance, leading to improved efficiency and precision. By analyzing data in real-time, AI can predict maintenance needs, reduce downtime, and enhance the overall reliability of servo-driven applications.

Tips: When implementing AI in servo systems, ensure that data collection processes are robust and that the algorithms are trained with relevant datasets. This allows for more accurate predictions and better decision-making capabilities.

Moreover, the future trends indicate a potential for even more complex interactions between servo motors and AI-driven systems. As machine learning continues to evolve, servo motors will likely become smarter, learning from past operations to improve future performance. This synergy not only paves the way for smarter manufacturing but also enhances the capabilities of robotics and automation across various industries.

Tips: Staying updated with advancements in AI technology is crucial for engineers and manufacturers. Regularly participating in workshops and following industry publications can provide insights into the latest trends and best practices.